Bearing saddle elastic pad and its preparation method and application

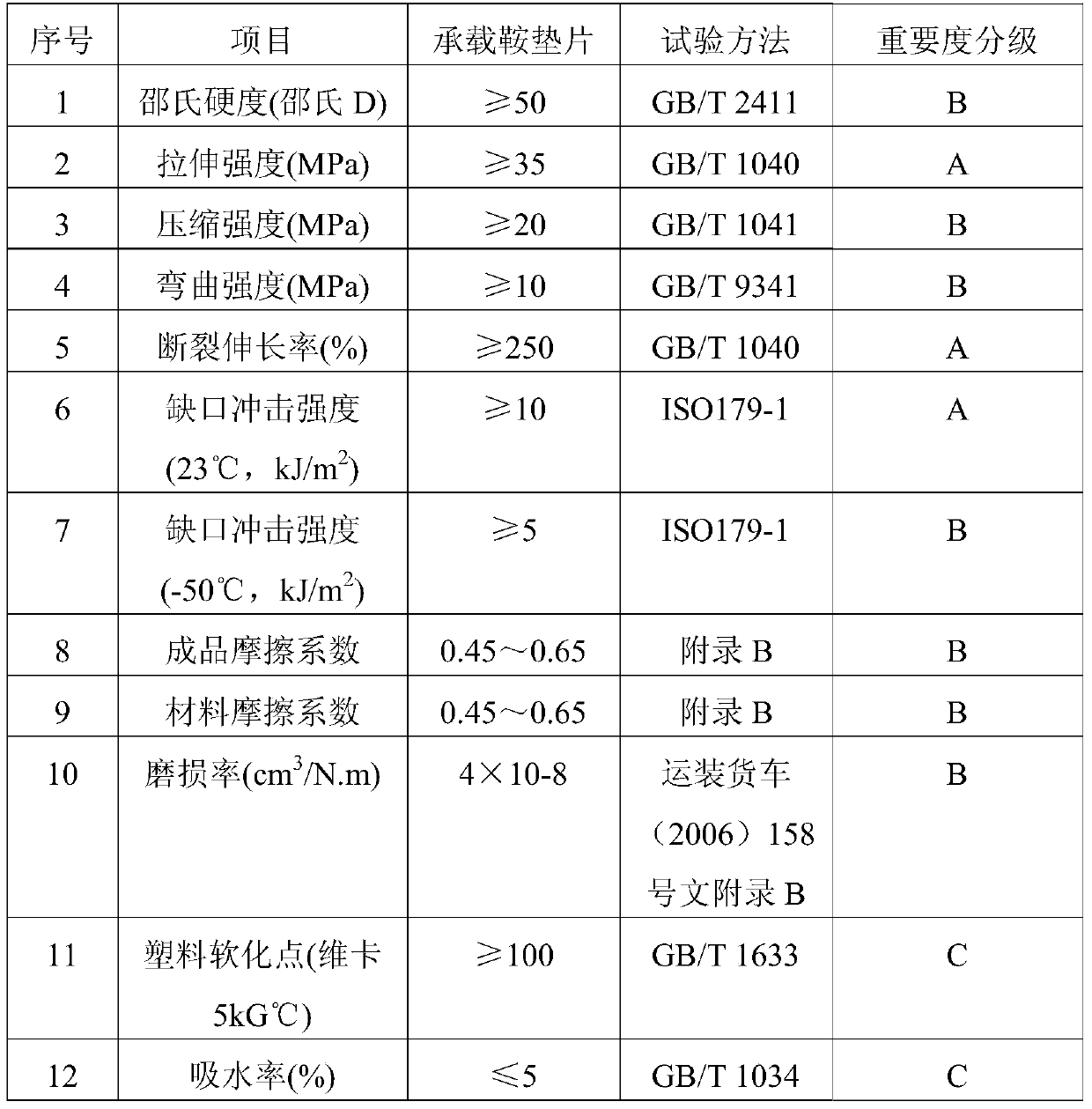

A technology for carrying saddles and elastic pads, applied in the field of elastic pads, can solve the problems of high assembly and production difficulty, insufficient improvement effect, insufficient improvement direction, etc., and achieves the effects of long service life, simple assembly and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

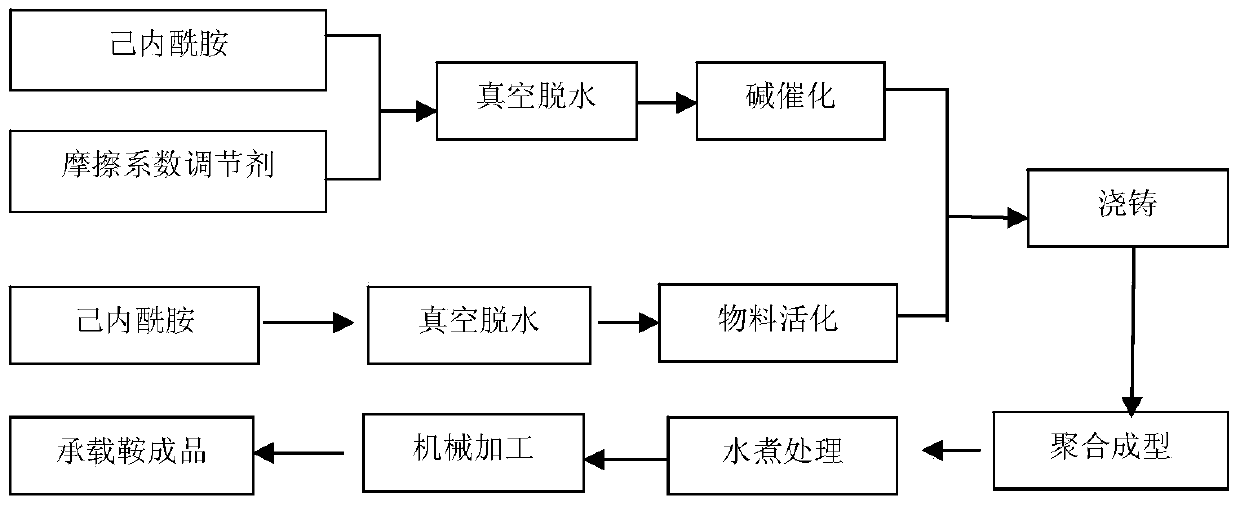

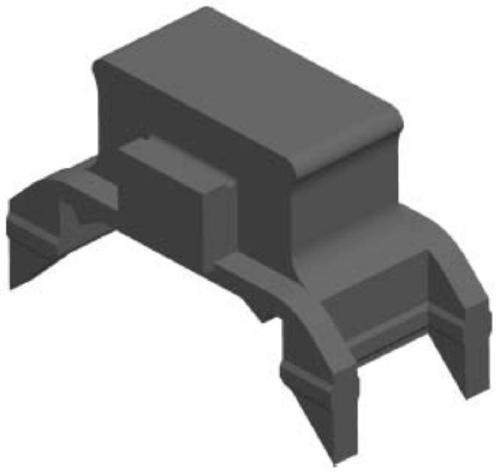

[0029] Such as figure 1 Shown, adopt following steps to prepare bearing saddle elastic pad of the present invention:

[0030] 1) Add 50 parts by weight of caprolactam and a friction coefficient modifier (hydroxyl-terminated polybutadiene liquid rubber) into the first reactor, and add another part of 50 parts by weight of caprolactam into the second reactor, melt and vacuum dehydrate for 10 minutes ;

[0031] 2) Add catalyst (sodium hydroxide) to the first reaction kettle, and vacuum dehydrate for 15 minutes;

[0032] 3) Add an activator (triphenylmethane triisocyanate) to the second reaction kettle, and vacuum dehydrate for 5 minutes;

[0033] 4) mixing the materials in the first reactor and the second reactor, injecting them into a molding mold, and polymerizing them into an integrated blank;

[0034] 5) The blank is boiled in water, and then machined into a bearing saddle elastic pad product. The saddle elastic pad prepared by the above method is used as a saddle elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com