Unmanned aerial vehicle body

A manufacturing method and unmanned aerial vehicle technology, which is applied to rotorcraft, motor vehicles, floats, etc., can solve problems such as insufficient endurance, blade damage, and large take-off weight, so as to achieve enhanced endurance and stability, and improve the overall structural strength , the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

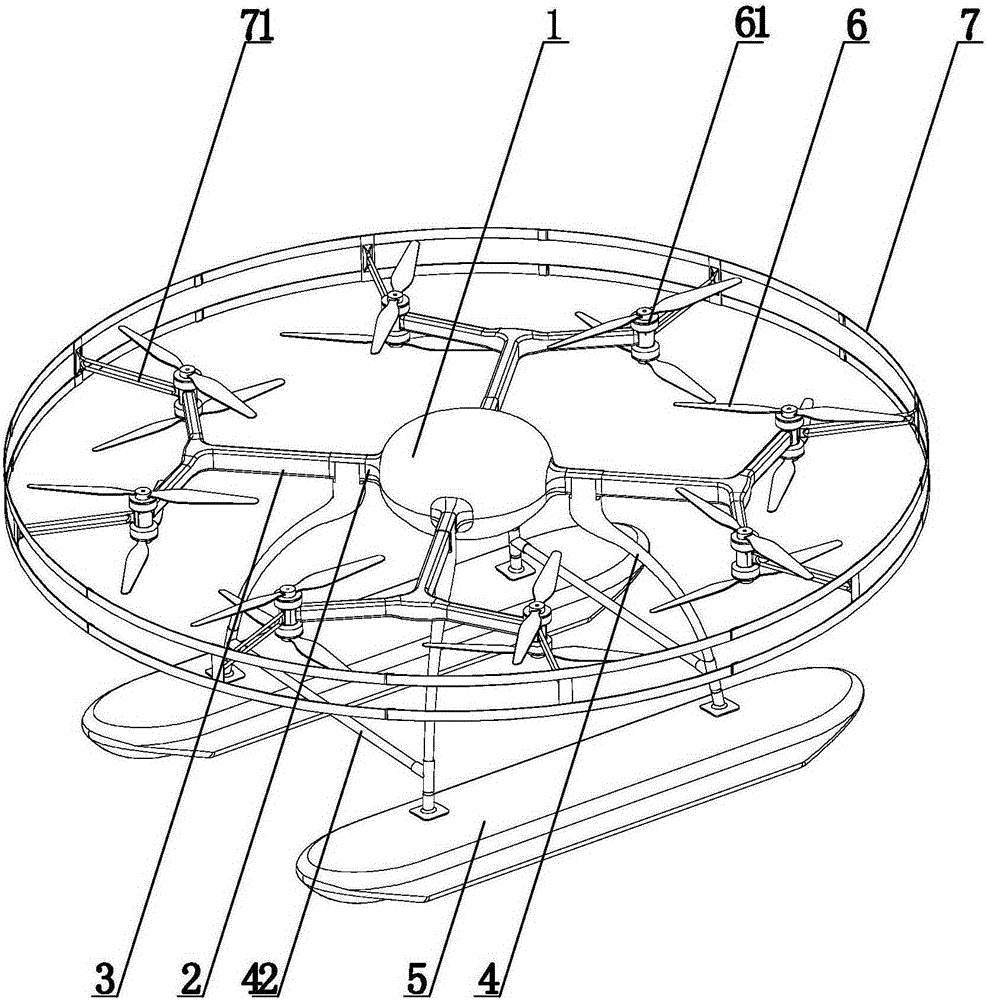

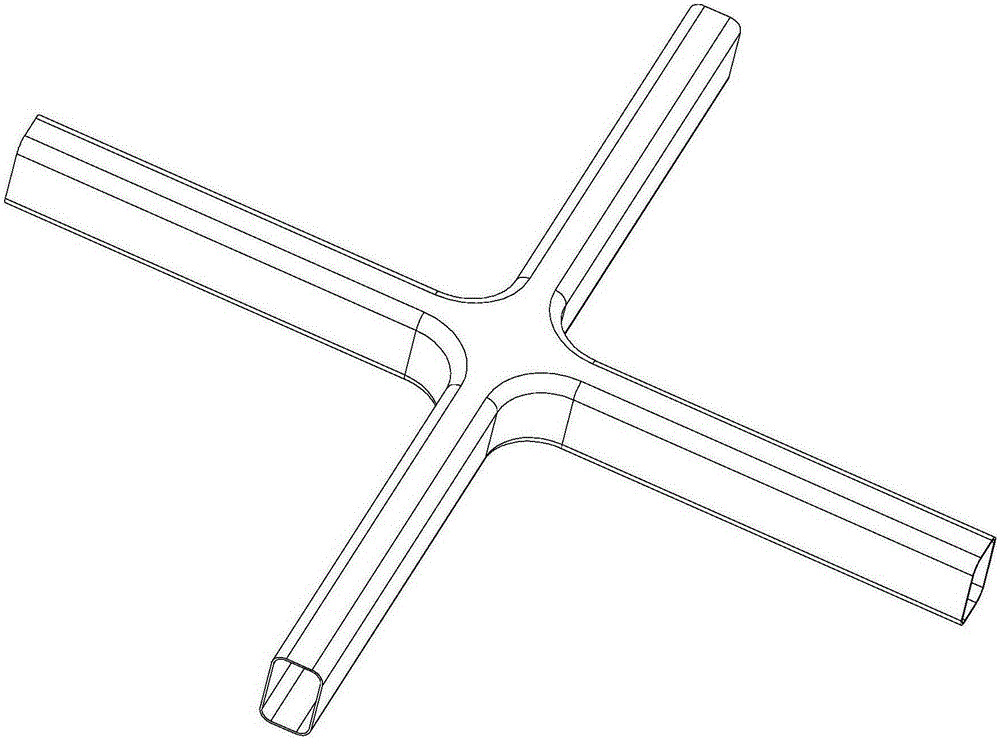

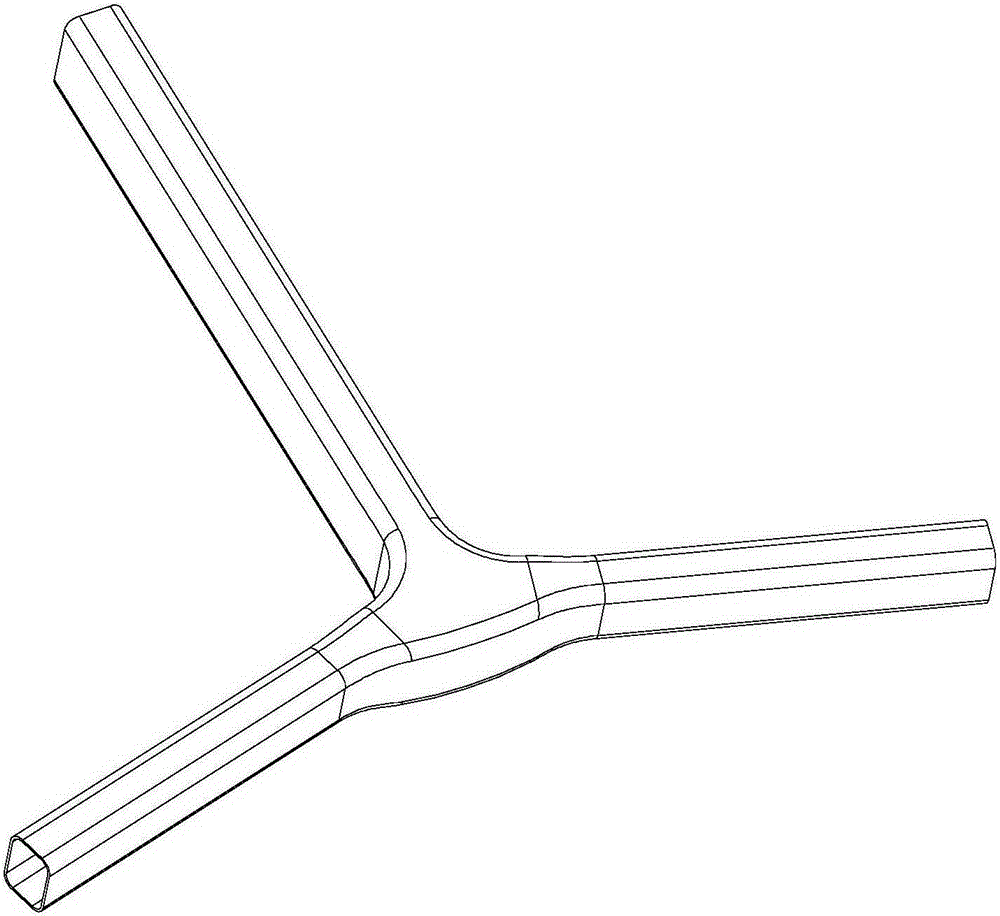

[0029] The drone body of this embodiment, combined with figure 1 , consists of cockpit 1, central support arm 2, cantilever 3, landing gear 4, buoys 5, rotor 6 and anti-collision ring 7, cockpit 1 is inside, anti-collision ring 7 is located outside the cockpit, buoys 5 are arranged in pairs, and are located at below the cockpit 1, which, combined with figure 2 , the central support arm 2 is provided with four, respectively symmetrically installed on the periphery of the cockpit 1, the central support arm 2 is a cross-shaped hollow structure; combined image 3 , each central support arm 2 corresponds to a cantilever 3, the cantilever 3 is a Y-shaped hollow structure, one end of the cantilever 3 is inserted into the central support arm 1, and the other two ends are connected to the inner periphery of the anti-collision ring 7 through the anti-collision support arm 71; The upper end of the landing gear 4 is connected with the central arm 2, and the lower end is fixed with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com