Compartment elevator roller wheel

A technology of elevators and rollers, which is applied to elevators, transportation and packaging in buildings. It can solve the problems of being easily worn by foreign objects, the high unit price of standard bearings, and the high cost of van elevator rollers, and achieves low production costs and limitations. Small, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

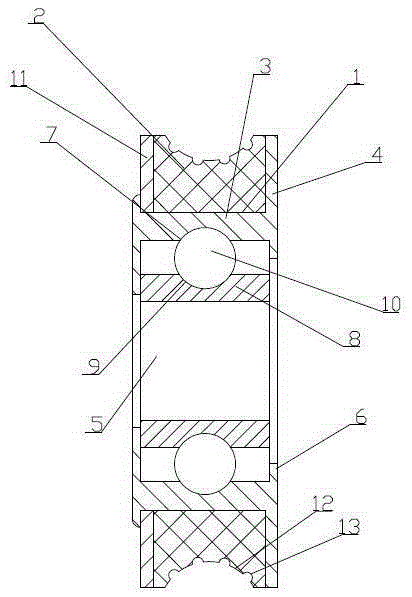

[0013] like figure 1 As shown in the figure, a van elevator roller provided in this embodiment includes a metal roller frame 1 and a non-metallic outer ring 2. The cross-section of the metal roller frame 1 is T-shaped, and the longitudinal portion 3 is a hollow structure, so The through hole 5 on the same side as the transverse part 4 on the longitudinal part 3 is provided with a limit ring 6 extending radially toward the through hole 5, and the inner hole wall of the through hole 5 is provided with a first stopper. The arc-shaped ring groove 7 is provided with a metal sleeve 8 in the above-mentioned through hole 5, and the outer surface of the metal sleeve 8 is provided with a second arc-shaped ring opposite to the above-mentioned first arc-shaped ring groove 7 groove 9, and balls 1110 are annularly distributed in the cavity formed by the first arc-sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap