How to obtain fine annealing temperature

A technology of annealing temperature and transition temperature, which is applied in the field of temperature acquisition, can solve the problems of inaccuracy and unspecific fine annealing temperature, and achieve the effect of improving uniformity and quality, and easy measurement and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

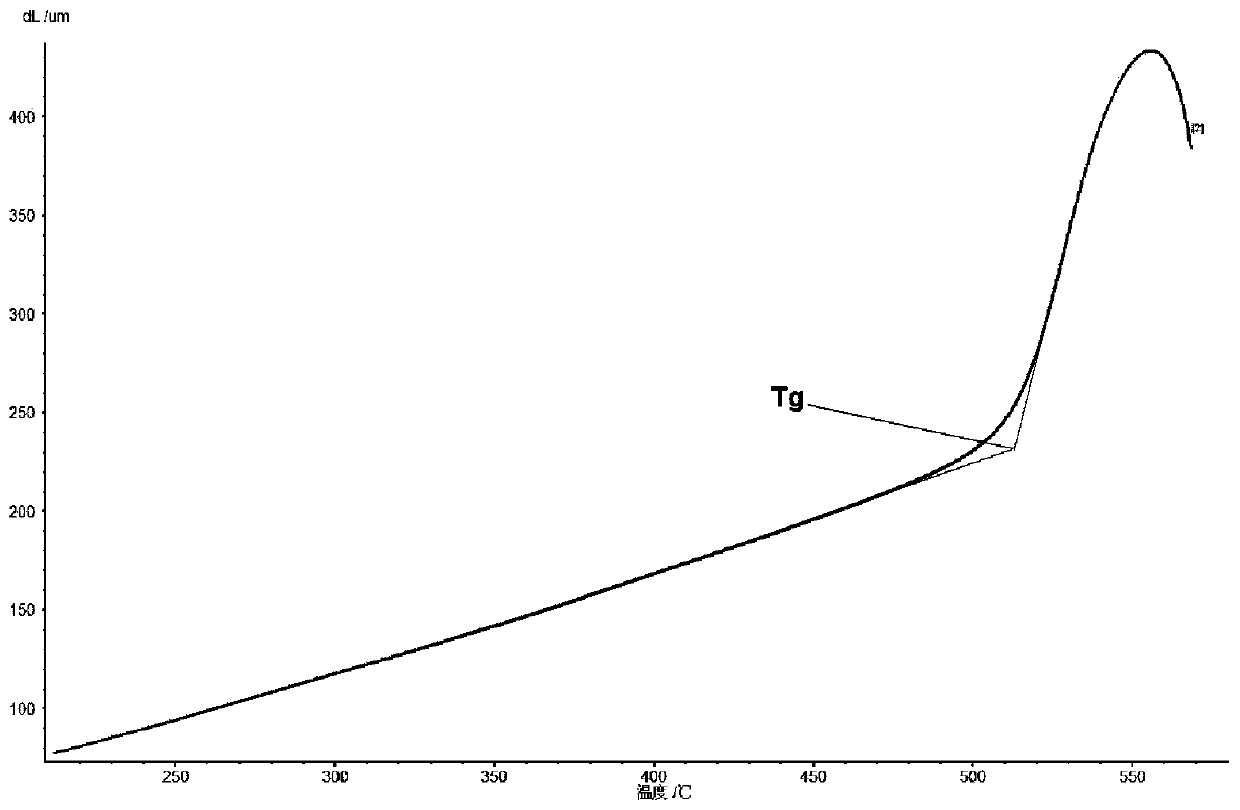

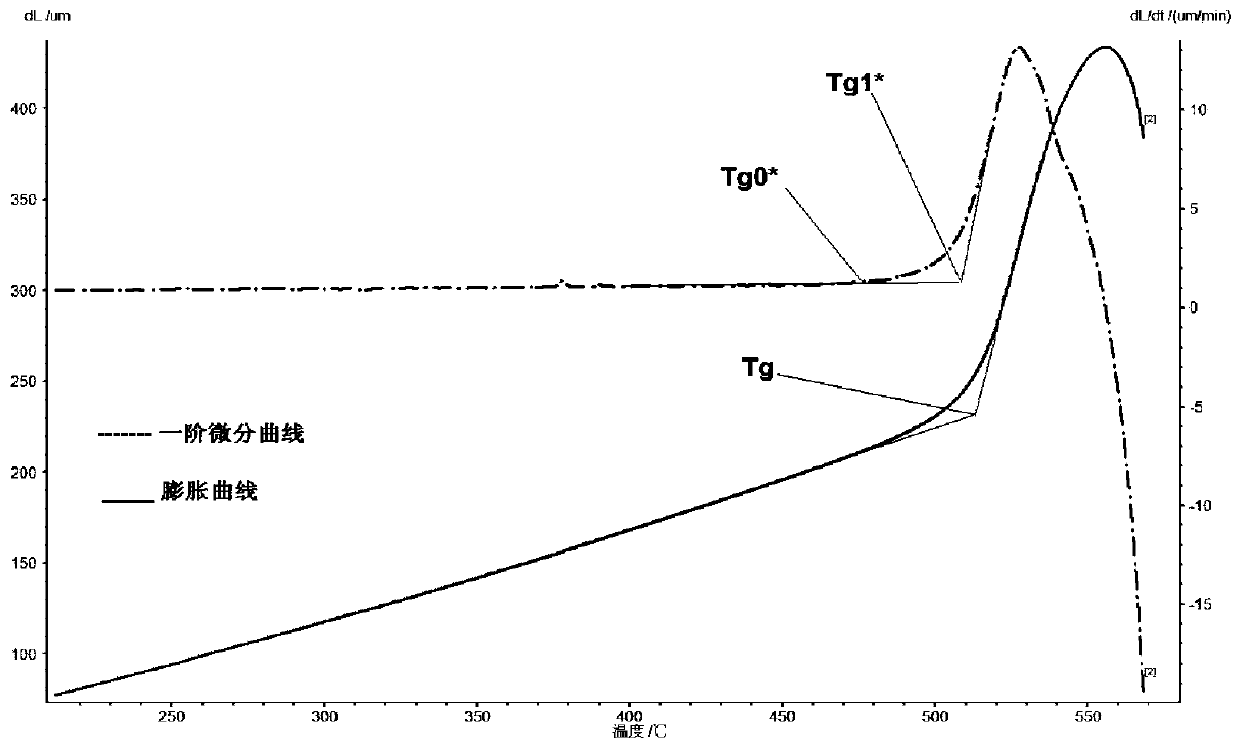

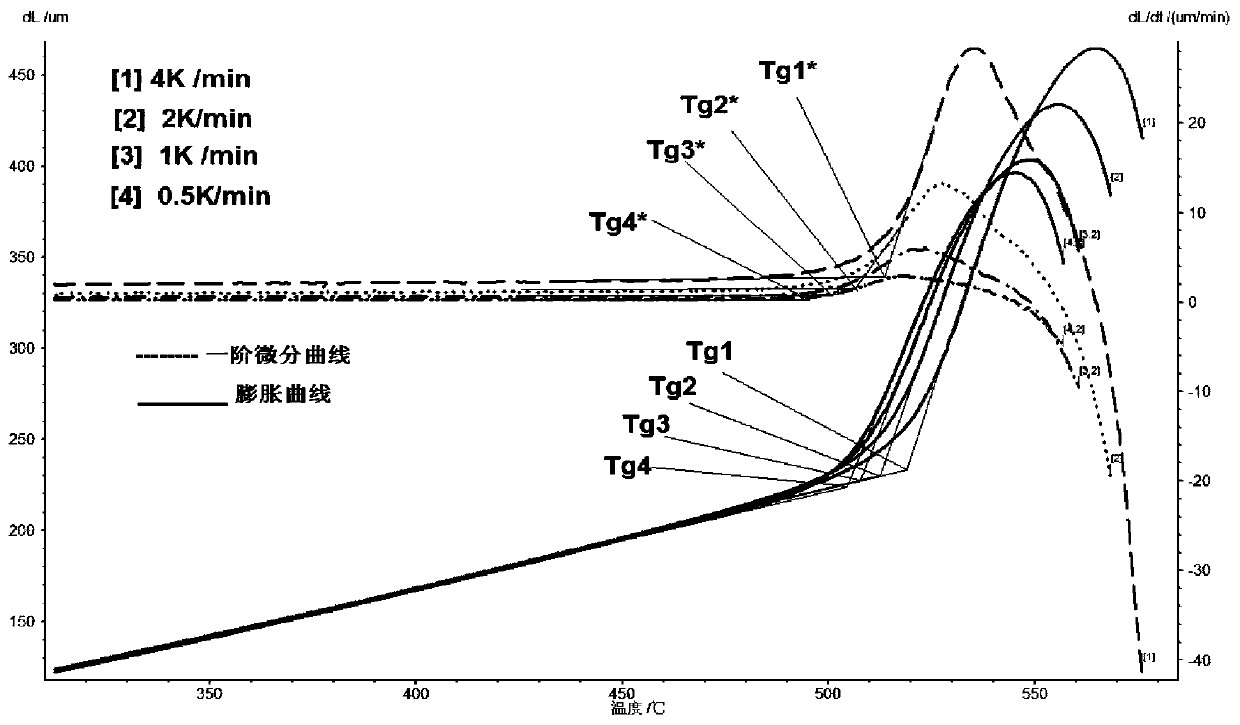

[0018] The DIL402PC thermal dilatometer from NETZSCH is used. The accuracy of the thermal expansion coefficient and the temperature calorific value of the instrument are corrected by the fused high-purity quartz standard sample of -100 ℃ ~ 900 ℃ provided by the instrument company. The measured standard sample data, temperature and standard Compared with the sample literature database, the measurement accuracy of the instrument meets 2×10 -7 / °C. The expansion coefficient and temperature accuracy of the instrument must be confirmed before the experiment. The glass sample requires uniform melting without bubbles, streaks and crystallization, Φ6×50mm, and the two end surfaces must be parallel. After measuring the length of the cleaned sample, put it into the measuring room of the instrument, set the same heating rate as the annealing rate, and test the sample to obtain the thermal expansion of the glass heated at 0.5°C / min~1°C / min close to the annealing rate curve, and then per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com