Guide carriage with fastening bore which is a component of a lubricant flow path

A technology of flow paths and guided vehicles, which is applied in the field of guided vehicles to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

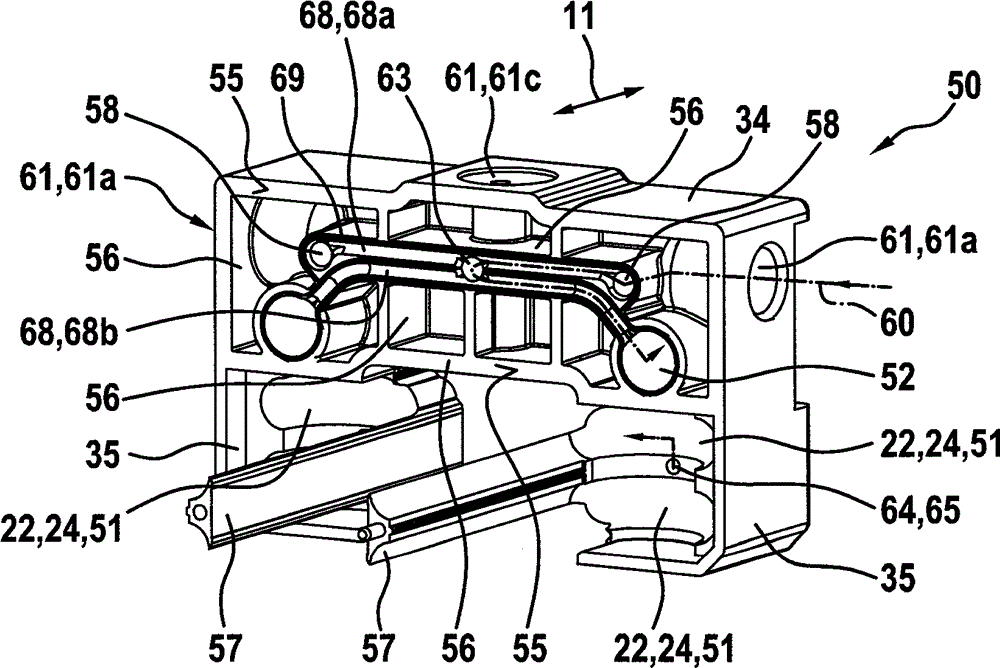

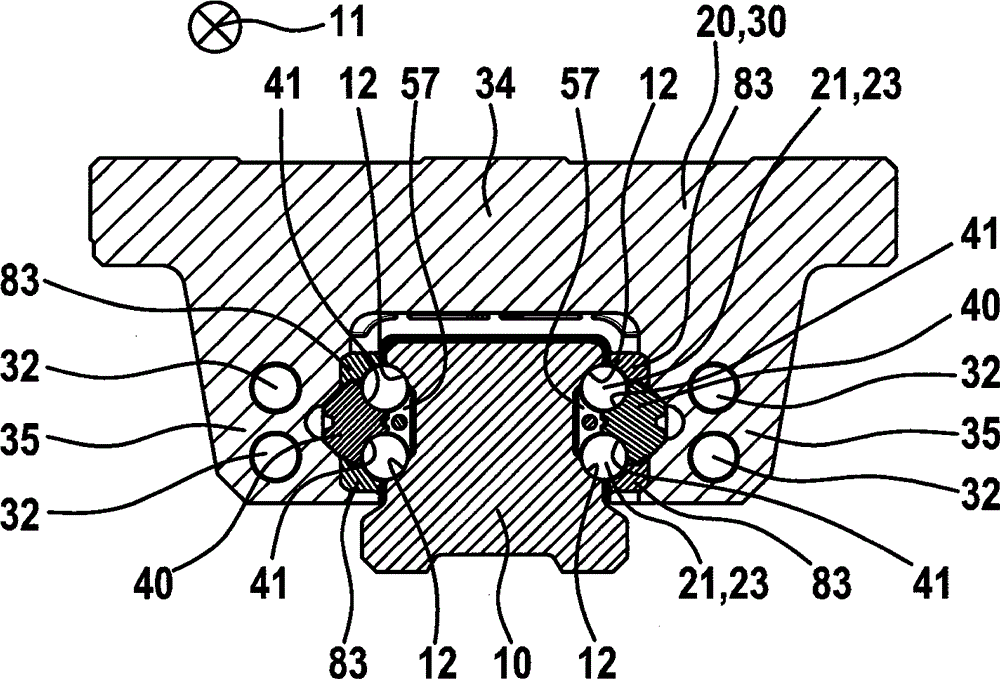

[0027] figure 1 An exploded view of the guided vehicle 20 according to the invention is shown. The guided vehicle 20 includes a main body 30 made of non-hardened steel, which extends along the longitudinal direction 11 in a substantially constant, U-shaped cross-sectional shape. A V-shaped groove 33 is respectively arranged on the inner surface of the U-shaped leg 35, and a separate rolling surface liner 40 made of hardened rolling bearing steel abuts against the groove 33, respectively. The two rolling surface linings 40 extend along the longitudinal direction 11 with a substantially constant cross-sectional shape, wherein the rolling surface linings respectively have two vehicle rolling surfaces 41, so the guided vehicle has a total of four rows Rolling element (in figure 2 Reference numeral 21). The present invention can also be applied to some guided vehicles, for which the hardened rolling surface of the vehicle is directly arranged on the main body 30.

[0028] Each end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com