Speed reduction drive device with damping, lubricating, cooling and air pressure balancing functions

A technology of deceleration transmission and air pressure balance, which is applied in the directions of transmission parts, gear lubrication/cooling, hoisting devices, etc., can solve the problems of poor heat dissipation performance of the reducer, damage to the transmission mechanism of the reducer, and increase in the temperature of the lubricating oil, etc. Lubrication and cooling effect, extended service life, effect of avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

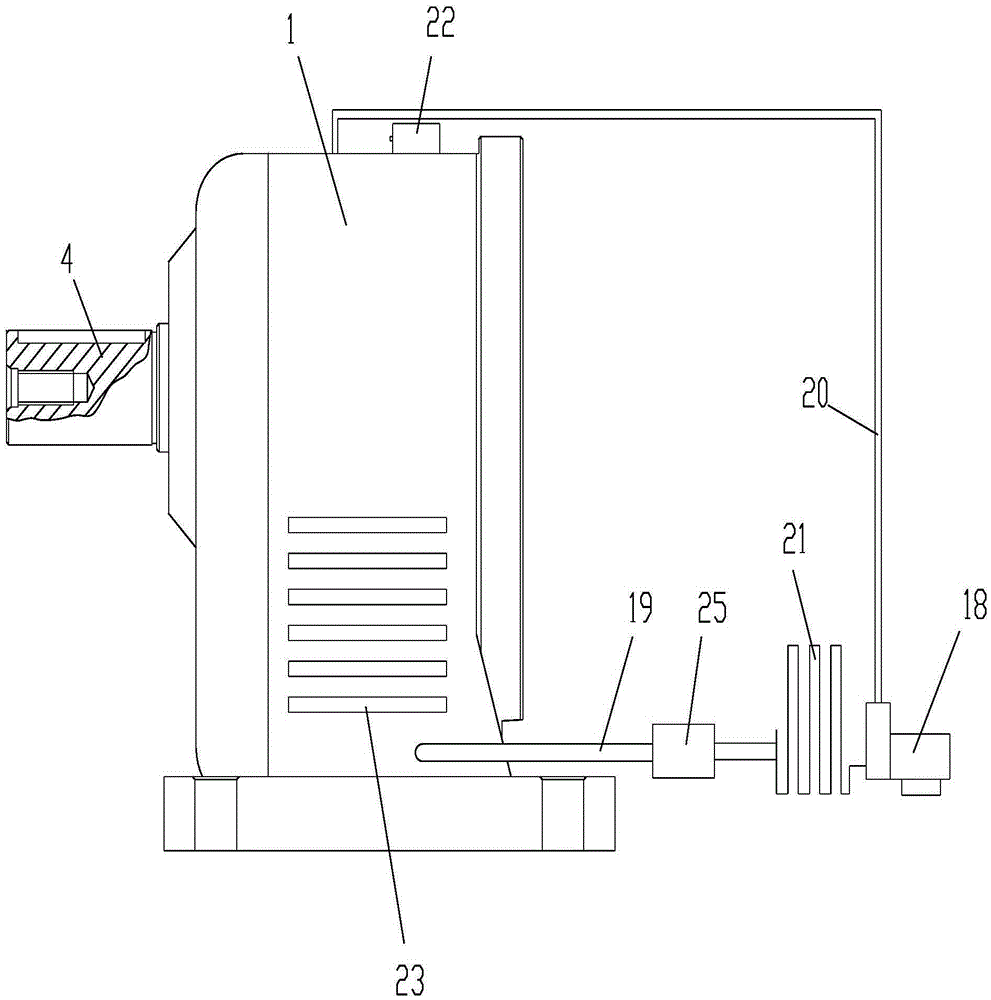

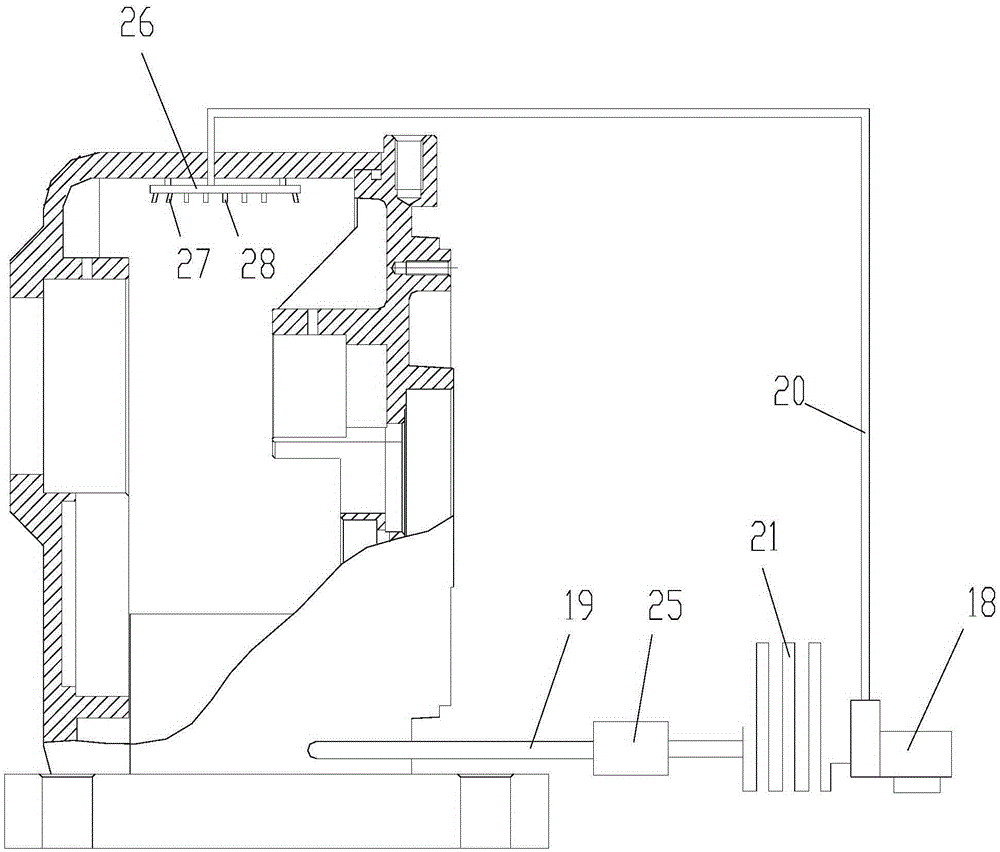

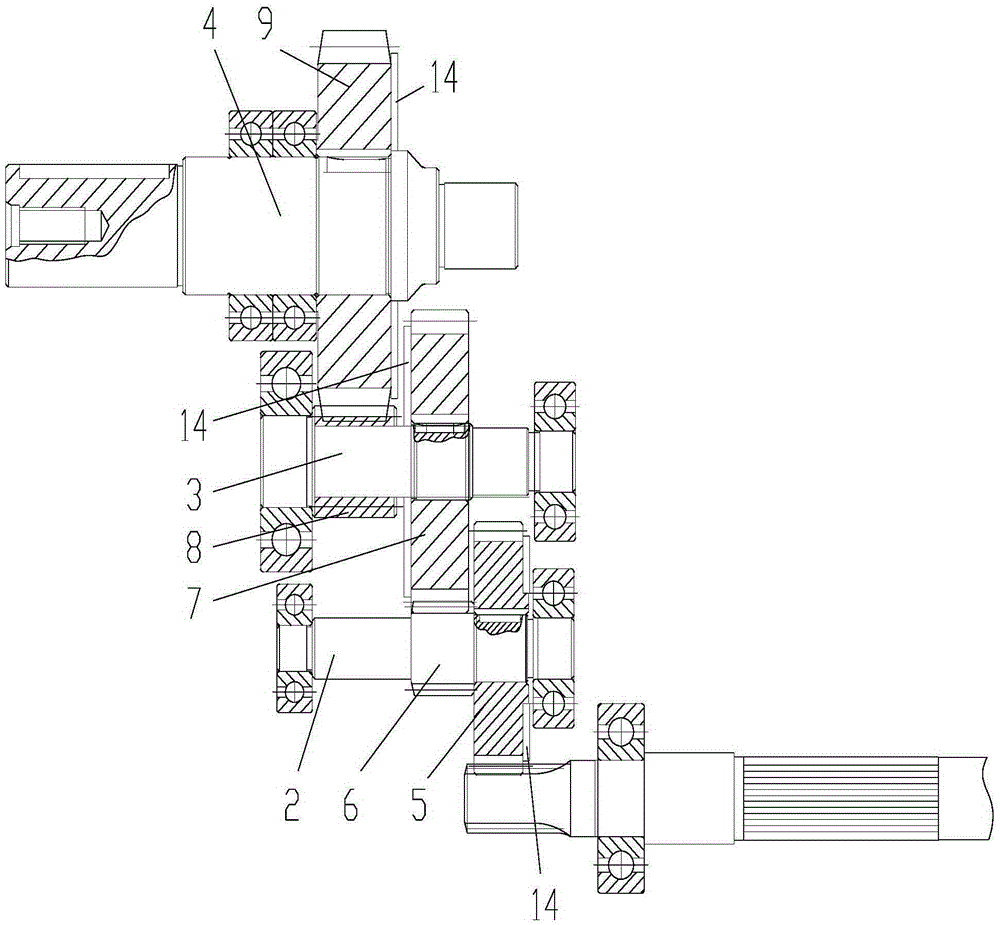

[0030] As shown in the figure, the deceleration transmission device with the functions of shock absorption, lubrication, cooling and air pressure balance in this embodiment includes a reducer housing 1 and a cylindrical gear transmission mechanism arranged in the reducer housing, and the cylindrical gear transmission mechanism includes through Bearings are arranged on the input shaft 2, the intermediate shaft 3 and the output shaft 4 on the reducer housing. The input shaft is provided with a first gear 5 and a second gear 6 with a diameter smaller than the first gear. The intermediate shaft is provided with The third gear 7 and the fourth gear 8 with a diameter smaller than the third gear, the output shaft is provided with a fifth gear 9, the spline teeth at the end of the rotor shaft mesh with the first gear, and the second gear and the third gear is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com