Manufacture method for cement sample used for simulating parent-rock porosity character

A production method and cement technology, applied in the preparation of test samples, etc., can solve the problems of large gaps in pore structure, reduce the efficiency and accuracy of physical simulation experiments, and achieve the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

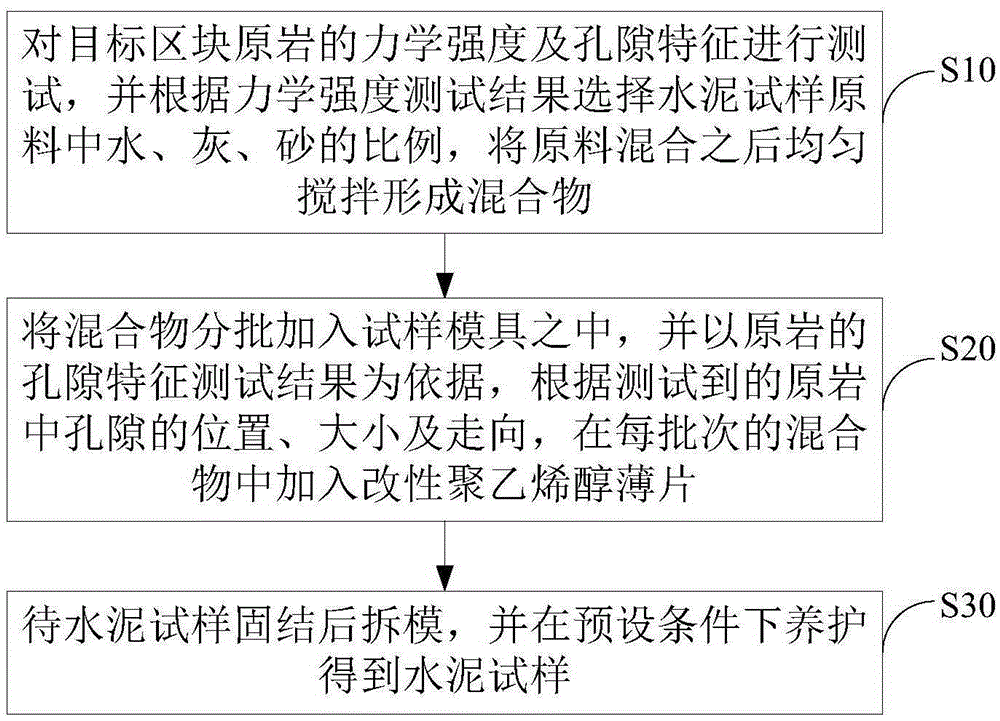

[0022] refer to figure 1 , in this preferred embodiment, a kind of preparation method of the cement sample that is used to simulate the pore characteristic of original rock, comprises the following steps:

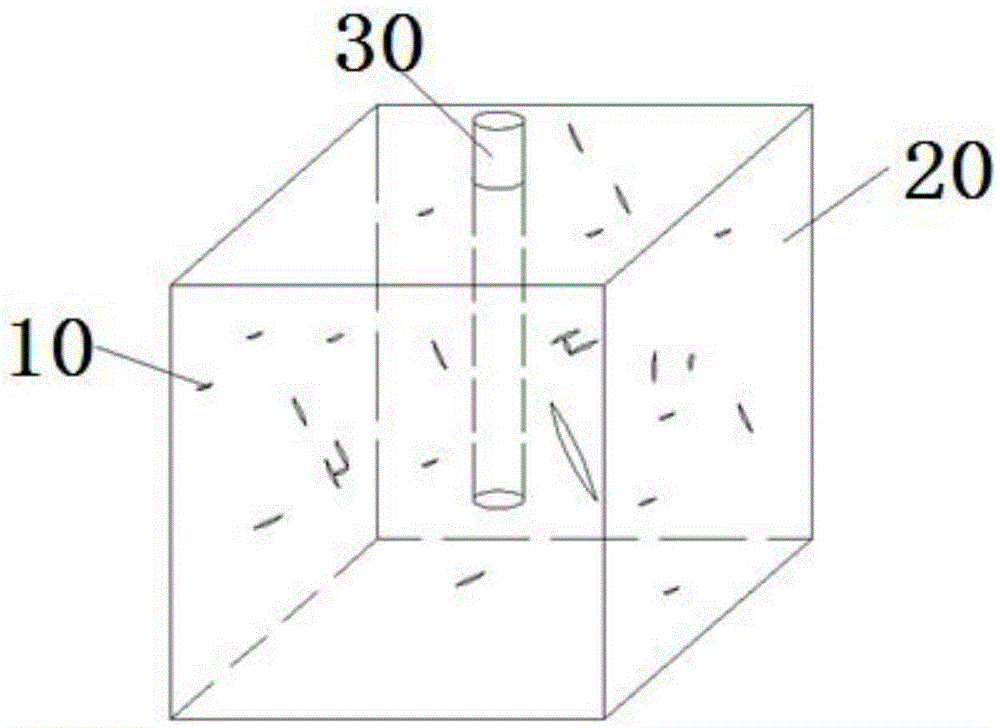

[0023] Step S10, testing the mechanical strength and pore characteristics of the original rock in the target block, and selecting the ratio of water, ash and sand in the raw materials of the cement sample 20 according to the mechanical strength test results, mixing the raw materials and uniformly stirring to form a mixture;

[0024] The original rock is subjected to compressive and flexural strength tests, and the mechanical strength test results are obtained. Based on the mechanical strength test results, a number of small samples with different ratios of water, ash, and sand are made, and several small samples ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com