Direct current breaker topology with bidirectional blocking function

A technology of DC circuit breaker and topology, which is applied in the field of DC circuit breaker topology, can solve the problems of inability to shut down the current, and the breaking time is difficult to meet the DC transmission system, and achieve the effect of low withstand voltage demand, light weight, and easy engineering realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

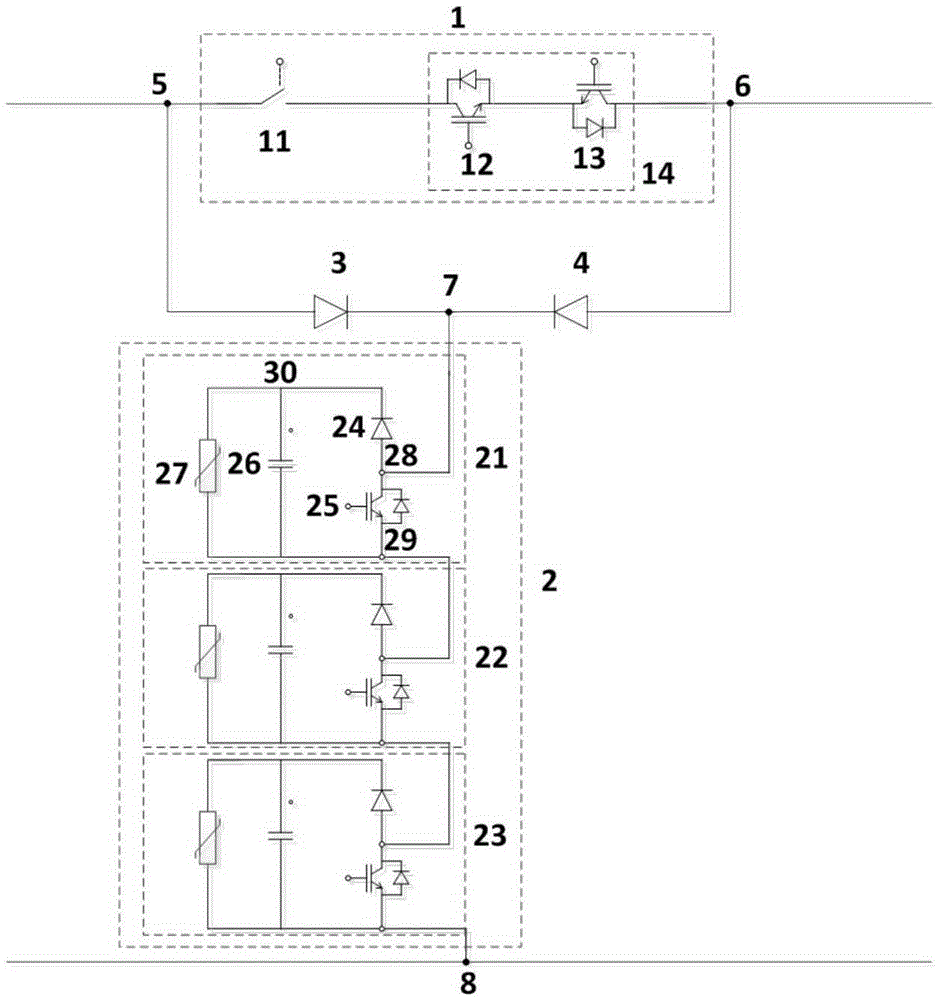

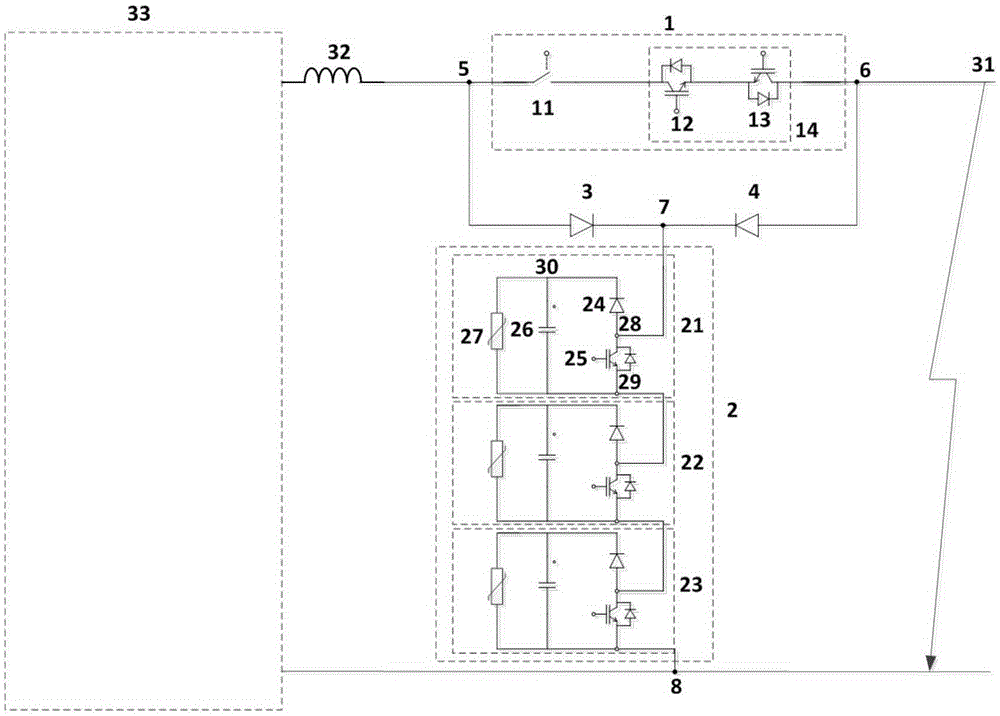

[0027] figure 2 Shown is a specific embodiment of the DC circuit breaker connected to the DC line, wherein the first lead-out terminal 5 of the DC circuit breaker is connected to one end of the inductor 32 on the DC line, and the other end of the inductor is connected to the positive pole of the converter station 33 , the second lead-out terminal 6 of the DC circuit breaker is connected to the short-circuit point 31, and the third lead-out terminal 8 of the DC circuit breaker is connected to the negative DC bus. The semiconductor device group 14 in the main circuit module is composed of a first IGBT module 12 and a second IGBT module 13 in reverse series. The fault current blocking module is composed of a first submodule 21 , a second submodule 22 and a third submodule 23 cascaded.

Embodiment 2

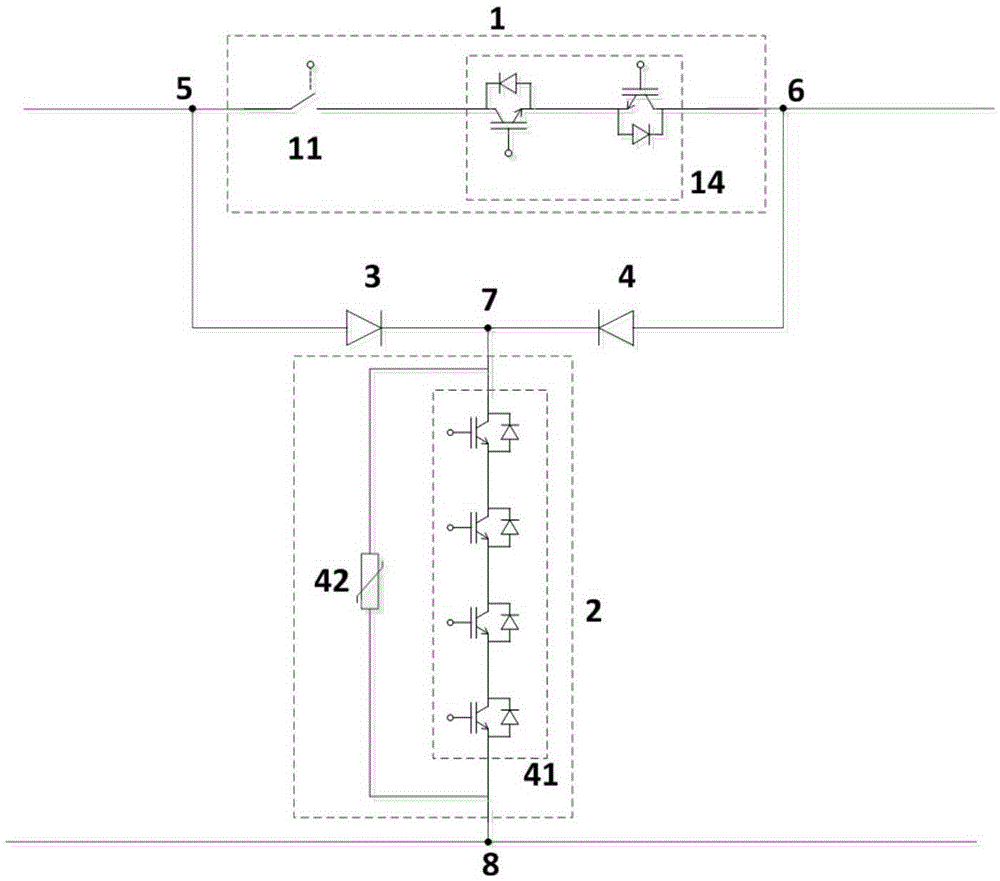

[0029] image 3 Shown is another implementation of the fault current blocking module. The fault current blocking module 2 is composed of a fully-controlled semiconductor device group 41 connected in parallel with an arrester 42, and the fully-controlled semiconductor device group 41 is composed of multiple IGBTs connected in series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com