A method of suppressing cogging torque of permanent magnet synchronous motor by using non-uniform stator slots

A permanent magnet synchronous motor, cogging torque technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problem of weakening mechanical strength of stator teeth, difficult processing and manufacturing, and unsuitable motors. and other problems, to achieve the effect of improving the back EMF waveform, avoiding the phenomenon of asymmetric lines, and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

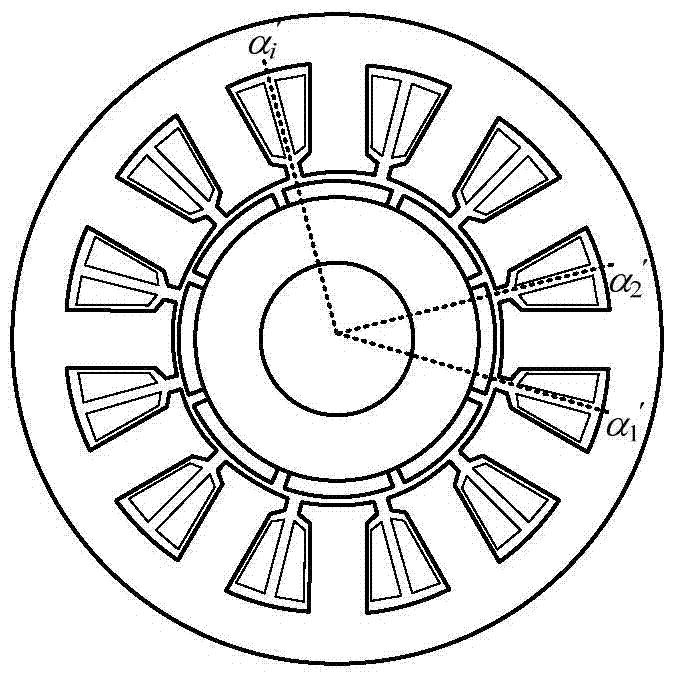

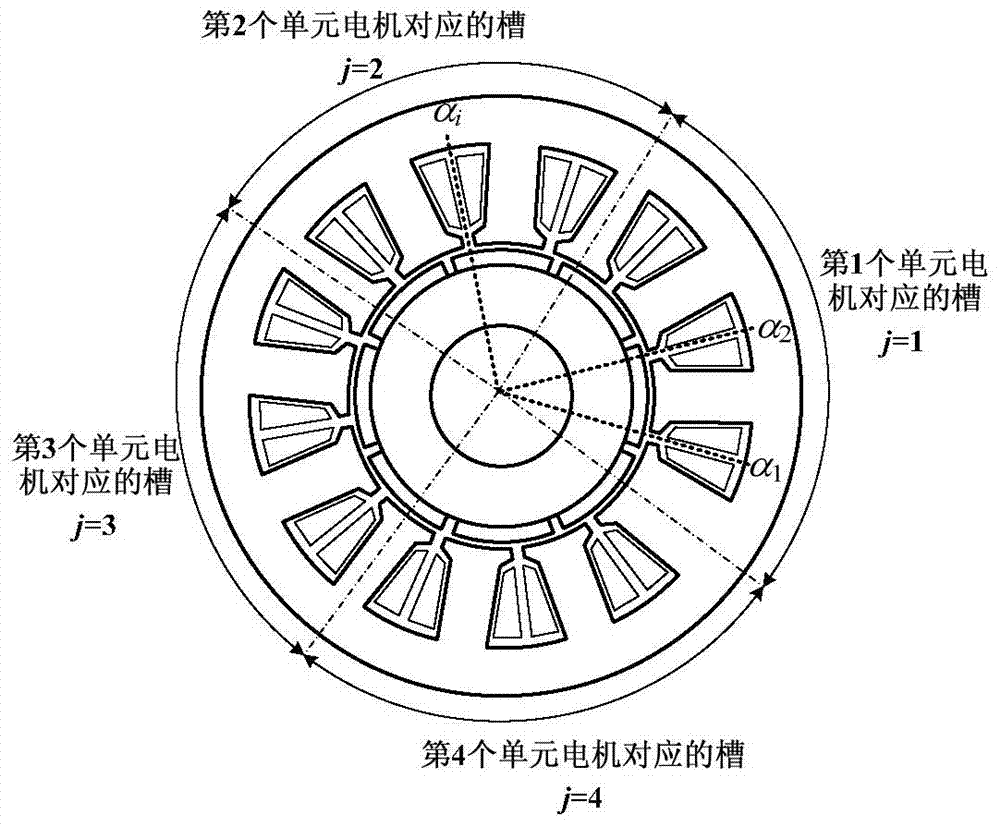

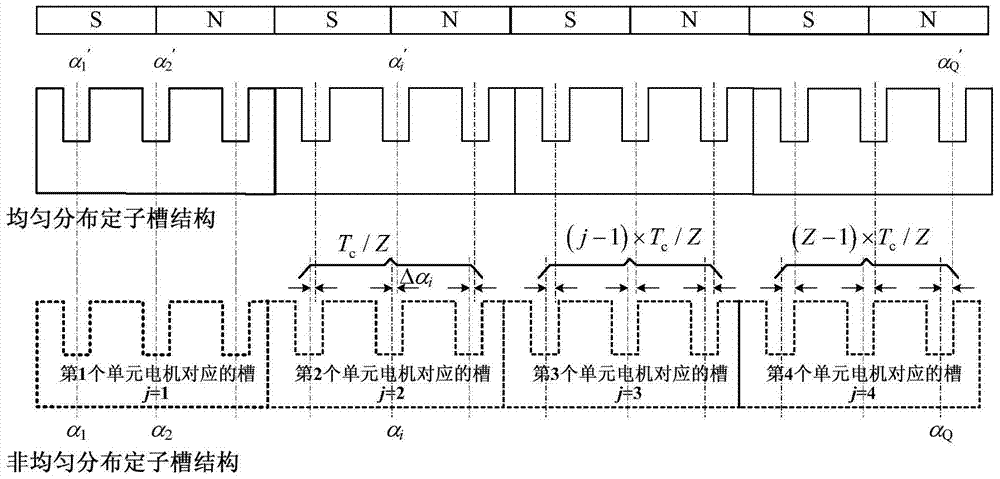

[0046] The method of using non-uniform stator slots to suppress the cogging torque of permanent magnet synchronous motors, under the condition that the size of the stator slots remain unchanged, the center position of the stator slots rotates and shifts in the circumferential direction of the stator,

[0047] The formula for the offset angle is,

[0048]

[0049] in,

[0050] Δα i is the offset angle of the i-th stator slot located in the j-th unit motor;

[0051]

[0052] i=1, 2, 3, ..., Q, and i is an integer;

[0053] Q is the number of stator slots;

[0054] j=1, 2, 3, ..., Z, and j is an integer;

[0055] Z is the number of unit motors included in the entire permanent magnet syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com