Sine wave rotor based on permanent magnet and outer rotor iron core eccentric structure design

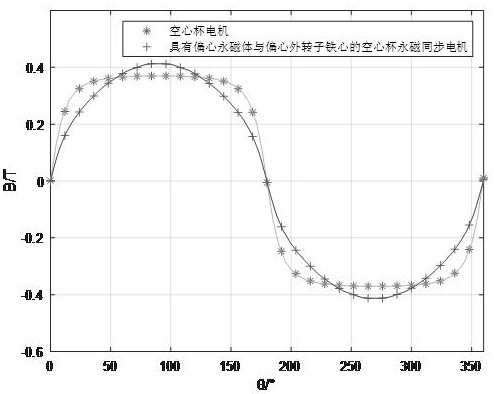

An eccentric structure and external rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit, etc., can solve the problem of affecting the performance and efficiency of the energy storage flywheel generator and the large harmonic content of the back electromotive force waveform , affect the performance and efficiency of the motor, and achieve the effect of improving the waveform of the back electromotive force, reasonable changes in the radial thickness of the air gap, and saving permanent magnet materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

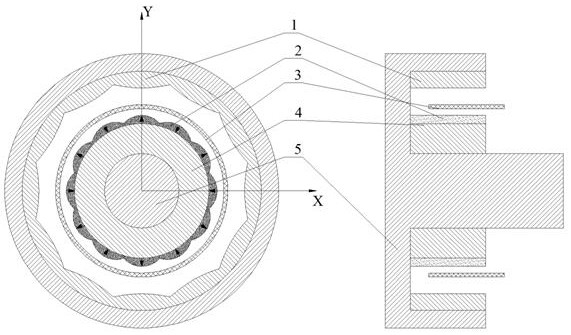

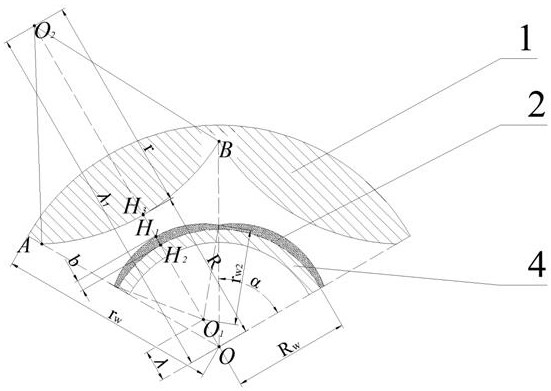

[0033] Embodiment 1 discloses a sine wave rotor designed based on a permanent magnet and an eccentric structure of an outer rotor iron core used in a permanent magnet synchronous motor with a magnetic levitation energy storage flywheel. Reference attached figure 1 And attached figure 2, which includes an outer rotor core 1, an eccentric permanent magnet 2, a magnetic levitation energy storage flywheel stator 3, an inner rotor core 4 and a rotor shaft 5, and the outer rotor core 1 and the inner rotor core 4 are fixedly connected to the rotor shaft 5, so that The outer rotor core 1 and the inner rotor core 4 rotate together with the rotor shaft 5 . In the specific setting process, the radially outer side of the outer rotor core 1 is installed on the outer end of the rotor shaft 5, and the radially inner side of the inner rotor core 4 is installed on the inner end of the rotor shaft. Several eccentric permanent magnets 2 are placed alternately along the radially outer side of ...

Embodiment 2

[0050] Embodiment 2 discloses a sine wave rotor designed based on a permanent magnet and an eccentric structure of an outer rotor iron core used in a hollow cup sine wave energy storage flywheel generator. Reference attached Figure 4 , attached Figure 5 And attached Figure 6 , which includes an outer rotor core 1 , an eccentric permanent magnet 2 , a tile-shaped magnetic isolation block 6 , a hollow cup stator 3 , an inner rotor core 4 and a rotor shaft 5 . Both the outer rotor core 1 and the inner rotor core 4 are fixedly connected to the rotor shaft 5 , so that the outer rotor core 1 and the inner rotor core 4 can rotate together with the rotor shaft 5 . In the specific setting process, the radially outer side of the outer rotor core 1 is installed on the outer end of the rotor shaft 5 , and the radially inner side of the inner rotor core 4 is installed on the inner end of the rotor shaft 5 . Several eccentric permanent magnets 2 are placed alternately along the radial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com