Liquid crystal display element, liquid crystal alignment film, and liquid crystal alignment treatment agent

A technology of liquid crystal alignment film and liquid crystal alignment, applied in coating, instrument, optics, etc., can solve the problem of high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0356] The following examples are given to illustrate the present invention in more detail, but they are not limitedly interpreted.

[0357] "Abbreviations of Compounds Used in Synthesis Examples, Examples, and Comparative Examples"

[0358] (liquid crystal)

[0359] L1: MLC-6608 (manufactured by MERCK CORPORATION)

[0360] (polymeric compound)

[0361] R1: a compound represented by the following formula [R1]

[0362] (photoinitiator)

[0363] P1: a compound represented by the following formula [P1]

[0364]

[0365] (specific side chain type diamine compound)

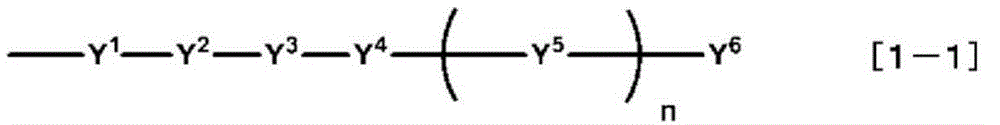

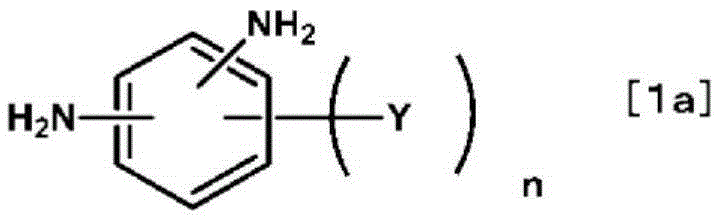

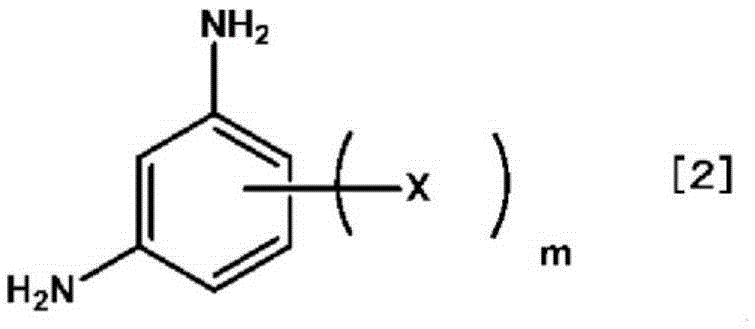

[0366] A1: 1,3-diamino-4-[4-(trans-4-n-heptylcyclohexyl)phenoxy]benzene (equivalent to formula [1-1])

[0367] A2: 1,3-diamino-4-[4-(trans-4-n-heptylcyclohexyl)phenoxymethyl]benzene (equivalent to formula [1-1])

[0368] A3: 1,3-diamino-4-{4-[trans-4-(trans-4-n-pentylcyclohexyl)cyclohexyl]phenoxy}benzene (equivalent to formula [1-1])

[0369] A4: Diamine compound represented by formula [A4] (corresponding to...

Synthetic example 1

[0419] Mix D1 (2.96g, 15.1mmol), A1 (2.91g, 7.65mmol), B1 (0.93g, 6.11mmol) and C2 (0.17g, 1.57mmol) in MCS (20.9g) and react at 40°C for 8 hours , A polyamic acid solution (1) having a resin solid content concentration of 25% by mass was obtained. The number average molecular weight of this polyamic acid was 24,600, and the weight average molecular weight was 73,900.

Synthetic example 2

[0421] Mix D2 (3.83g, 15.3mmol), A2 (6.04g, 15.3mmol) and B1 (2.33g, 15.3mmol) in MCS (26.4g), react at 50°C for 2 hours, add D1 (2.94g, 15.0 mmol) and MCS (23.8 g) were reacted at 40° C. for 6 hours to obtain a polyamic acid solution (2) whose resin solid content concentration was 25% by mass. The number average molecular weight of this polyamic acid was 16,800, and the weight average molecular weight was 55,900.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com