Liquid crystal alignment treatment agent, liquid crystal alignment film, and liquid crystal display device

A technology of liquid crystal display elements and liquid crystal alignment films, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of increased voltage and power consumption, and achieve high adhesion, good scattering characteristics, and good optical characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0200] As the preparation method of liquid crystal composition, can enumerate: the method of mixing liquid crystal, polymerizable compound, and specific liquid crystal additive compound together; Mix polymerizable compound and specific liquid crystal additive compound in advance, then mix the obtained mixture with liquid crystal mixed approach.

[0201] Among them, in the present invention, a method of mixing a polymerizable compound and a specific liquid crystal additive compound in advance, and then mixing the obtained mixture with a liquid crystal is preferable.

[0202] In the case of preparing a liquid crystal composition as described above, heating may be performed depending on the solubility of the polymerizable compound and the specific liquid crystal additive compound. The temperature at this time is preferably lower than 100°C.

[0203]

[0204] The substrate used for the liquid crystal display element is not particularly limited as long as it is a substrate with ...

Embodiment

[0217] Hereinafter, the present invention will be described more specifically with reference to examples, but the present invention is not limited thereto.

[0218] Abbreviations used hereinafter are as follows.

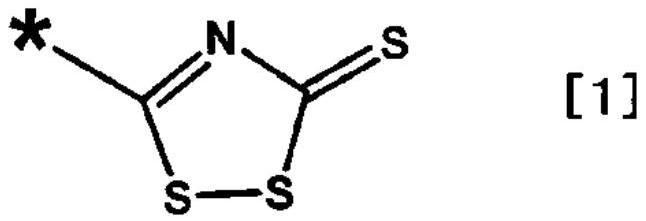

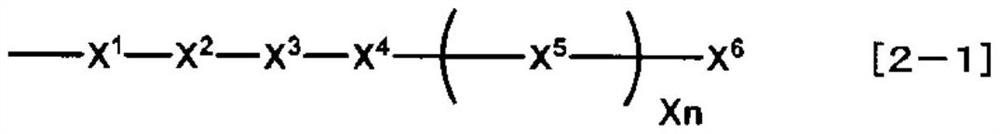

[0219] "Specific Compounds"

[0220]

[0221] "Compounds used in polyimide-based polymers"

[0222]

[0223]

[0224]

[0225]

[0226]

[0227]

[0228]

[0229]

[0230] "Crosslinking compound"

[0231]

[0232] "solvent"

[0233] NMP: N-methyl-2-pyrrolidone.

[0234] γ-BL: γ-butyrolactone.

[0235] BCS: Ethylene glycol monobutyl ether.

[0236] PB: Propylene glycol monobutyl ether.

[0237] PGME: Propylene Glycol Monomethyl Ether.

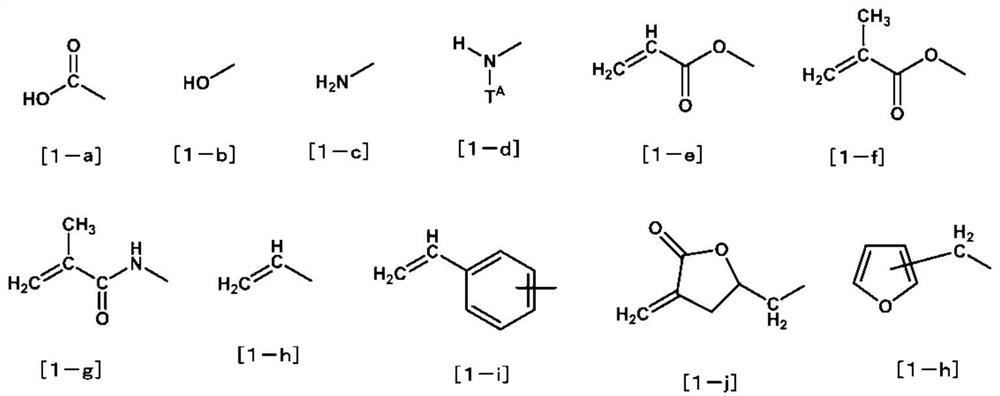

[0238] "Compounds Used in Liquid Crystal Compositions"

[0239]

[0240]

[0241]

[0242] R1: IBXA (manufactured by Osaka Organic Chemical Industry Co., Ltd.)

[0243] R2: KAYARAD FM-400 (manufactured by Nippon Kayaku Co., Ltd.)

[0244] R3: KAYARAD HX-220 (manufactured by Nippon Kayaku Co., ...

Embodiment 2

[0290] T1 (0.13g) and NMP (16.0g) were added to the polyamic-acid solution (2) (10.0g) obtained by the method of the synthesis example 2, and it stirred at 25 degreeC for 4 hours. Then, BCS (15.7g) was added, it stirred at 25 degreeC for 6 hours, and obtained the liquid-crystal aligning agent (2). Abnormalities such as turbidity and precipitation were not observed in this liquid-crystal aligning agent, and it was a homogeneous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com