Spray arm assembly of dishwasher and dishwasher having same

A spray arm assembly and dishwasher technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, household utensils, etc., can solve the problem of reducing cleaning effect, insufficient washing, and washing dead zone and other problems, to achieve the effect of expanding the washing area, good washing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

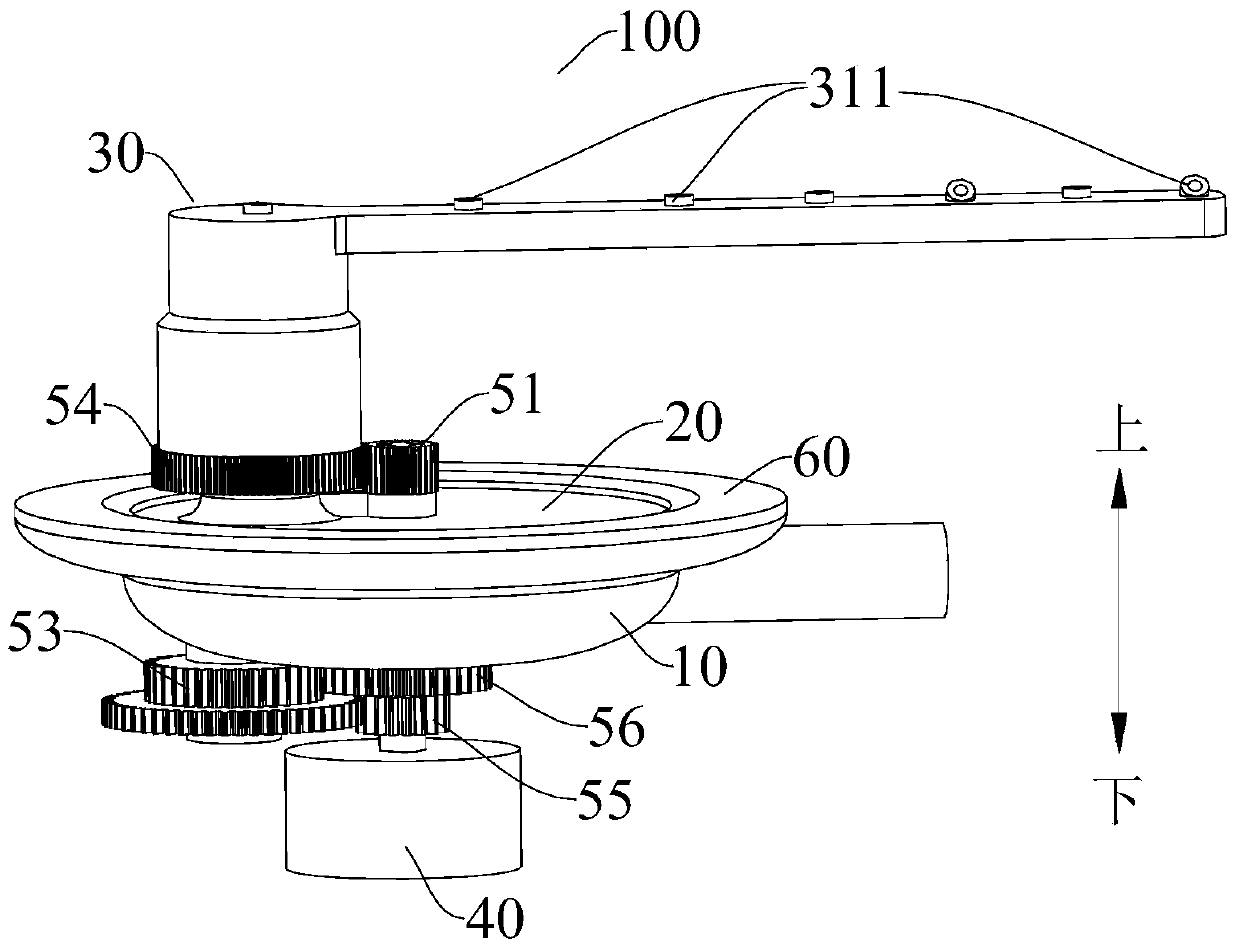

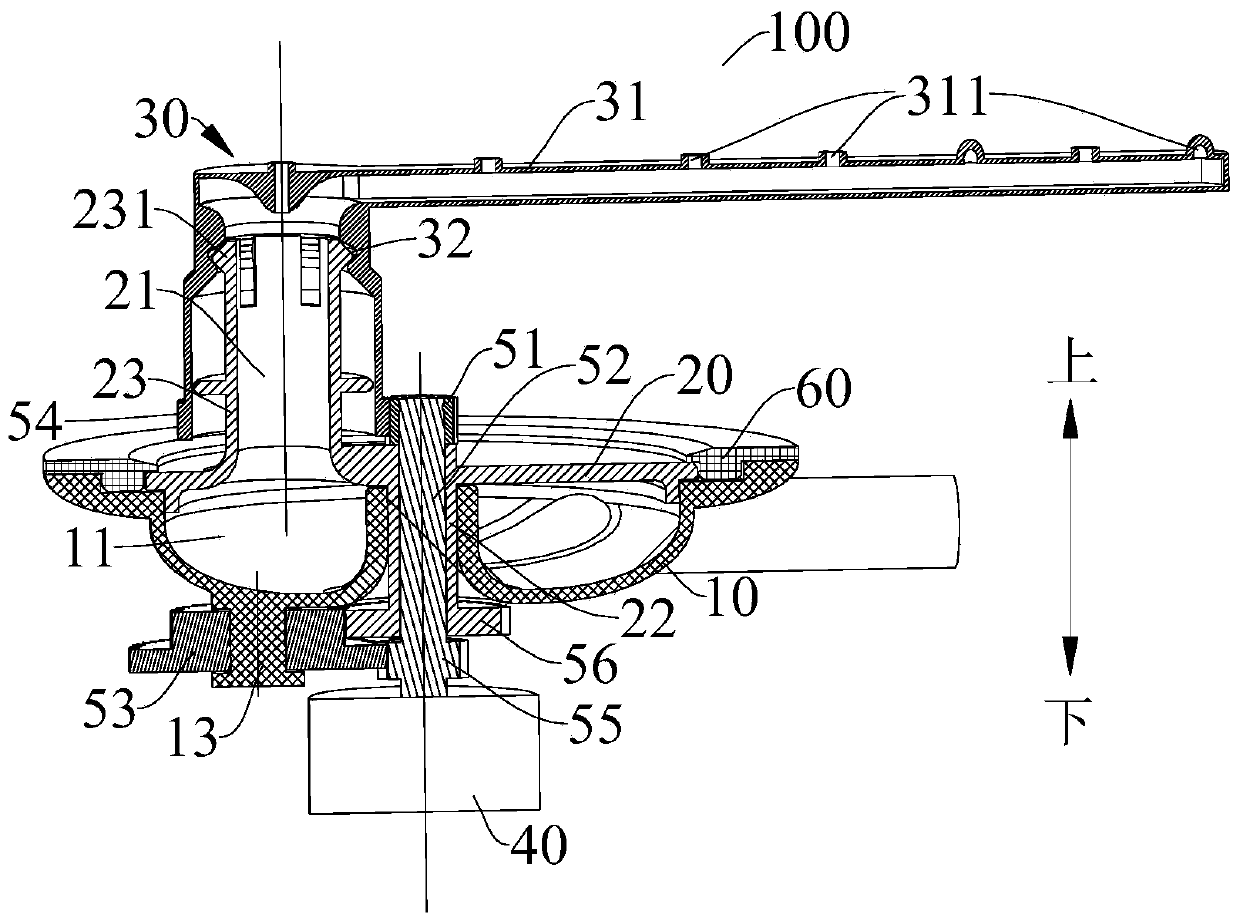

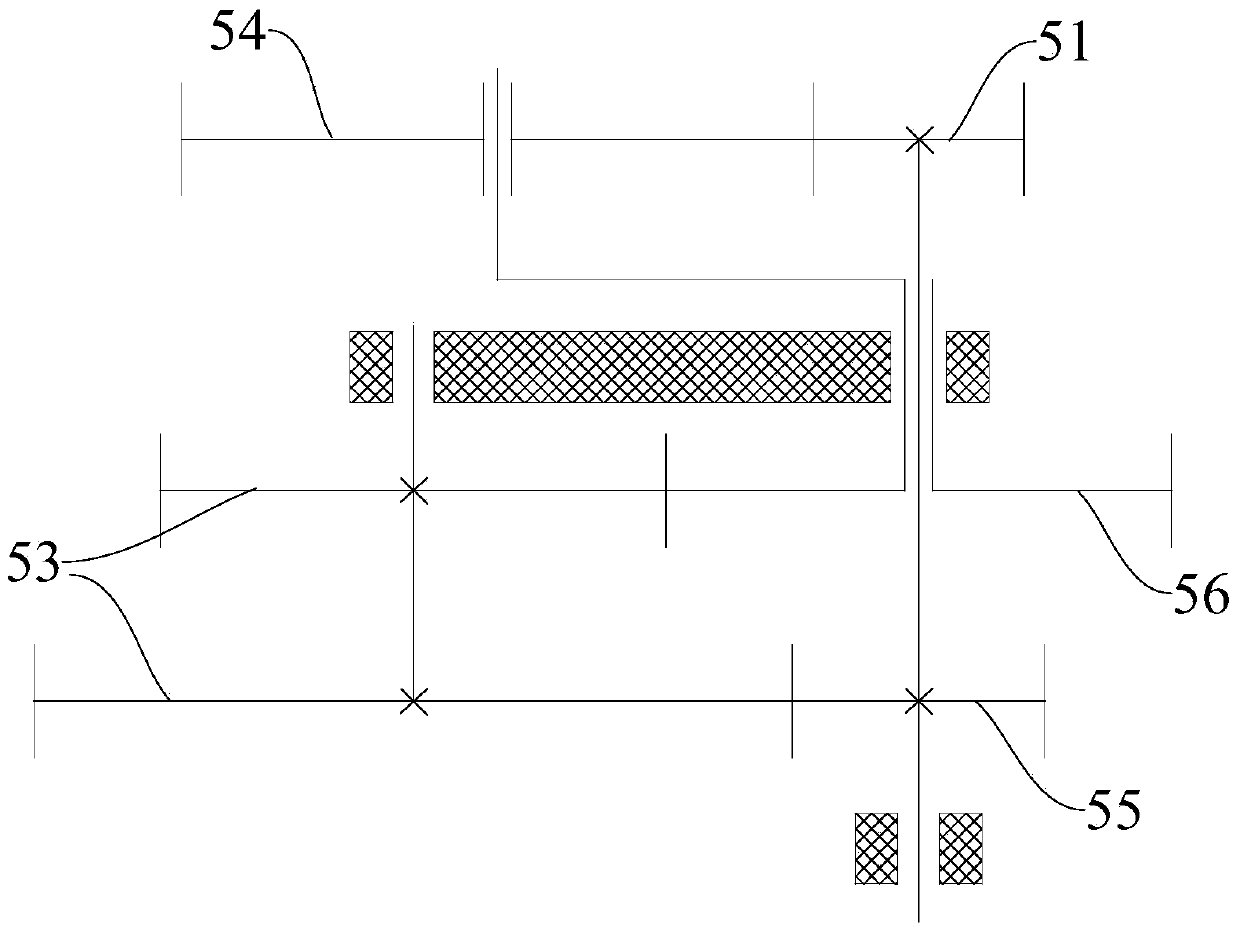

[0081] like Figure 1 to Figure 9 As shown, in this embodiment, the first central gear 51 is fixed at the central position of the bottom of the dishwasher liner, and a spline hole is opened on the inner wall of the first central gear 51, and four spline holes are arranged in the spline hole. Protrusion 511, when installing, insert the first central gear 51 on the spline shaft of the drive shaft 52 until the four protrusions 511 buckle the four grooves 521 on the spline shaft to realize the first central gear 51 and the drive shaft 52 fixed connections. The water storage chamber 11 of the bottom case 10 is an annular flow channel, and the side wall of the bottom case 10 is provided with a water inlet 12, and the washing water enters the water storage chamber 11 roughly along the tangential direction, and then flows along the annular flow channel to fill the entire The water storage chamber 11 finally flows out from the water inlet channel 21 of the spray arm base 20 and flows ...

Embodiment 2

[0090] like Figure 10 As shown, in this embodiment, the gear ratio of the first sun gear 51 and the planetary gear 54 is 1:3, and the spray arm body 30 has two spray arms 31, that is, two spray arms 31 extend outward from the center of the planetary gear 54. Spray arms 31, and the two spray arms 31 are arranged diagonally, with a phase difference angle of 180°, and a group of spray holes 311 are set on the two spray arms 31 respectively. According to the gear ratio 1:3 of the first central gear 51 and the planetary gear 54 and the external meshing relationship, there is a phase difference angle between the motion trajectories of the two spray arms 31, which is equal to 3 / of the phase difference angle between the two spray arms 31 2. Specifically, it is 270°, that is, the two groups of motion trajectories are perpendicular to each other.

[0091] The nozzle holes 311 on the two nozzle arms 31 respectively constitute characteristic long epicycloidal motion trajectories, which...

Embodiment 3

[0093] like Figure 11 As shown, in this embodiment, the gear ratio of the first sun gear 51 and the planetary gear 54 is 1:3, and the spray arm body 30 has three spray arms 31, that is, three spray arms 31 protrude from the center of the planetary gear 54 Spray arm 31. Two pairs of the three spray arms 31 are separated by 120°. Each spray arm 31 has a set of spray holes 311 respectively. There is a phase difference angle between the motion trajectories of the spray arms 31, which is equal to 3 / 2 of the phase difference angle between the spray arms 31, namely 180° and 360°.

[0094] Each group of nozzle holes 311 of the three spray arms 31 constitutes a characteristic long-width epicycloidal trajectory, and its characteristics are consistent with the description of Embodiment 1, and will not be repeated here. Moreover, since the phase differences between the motion trajectories of the three groups of nozzle holes 311 are 180° and 360°, the three groups of trajectory lines have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com