Compound hardware die

A hardware and mold technology, applied in the field of composite hardware molds, can solve the problems of difficult mold work, heavy workload, and inability to adjust the stamping stroke of the mold, and achieve the effect of simple installation workload, long practical life, and simple mold matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

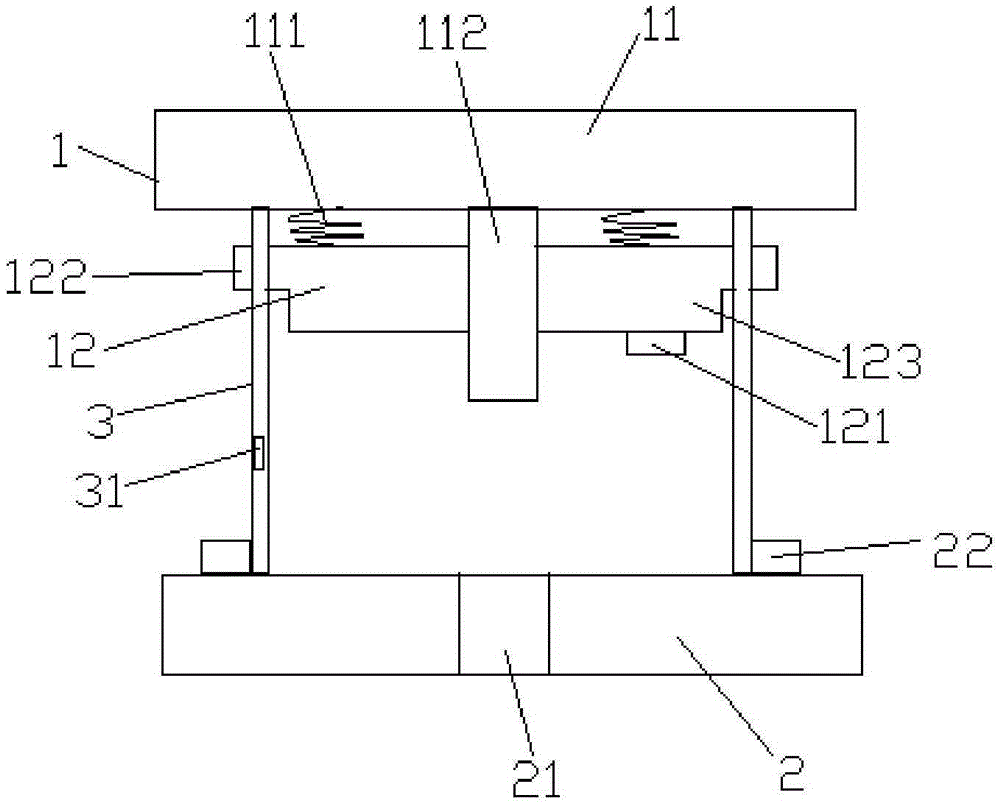

[0029] like figure 1 As shown, a composite metal mold includes an upper mold 1 , a lower mold 2 and a lifting guide post 3 .

[0030] The upper mold includes a hardware mold and an etching mold, wherein the etching mold is coaxially arranged between the hardware mold and the lower mold. Both the metal mold and the lower mold are simple metal molds, so the production is simple and the cost investment is low.

[0031] The etching mold includes a contour etching mold and an ear handle integrally arranged on the outer periphery of the contour etching mold.

[0032] The lifting guide column connects the hardware mold with the lower mold, and passes through the ear handle of the etching mold.

[0033] The top of the etching mold is connected with the hardware mold by a spring.

[0034] The metal mold is provided with a punch t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com