Aluminum alloy high-speed casting and rolling technology

An aluminum alloy, high-speed technology, applied in the field of aluminum alloy high-speed casting and rolling, can solve the problems of easy-to-stick rollers, less varieties of cast-rolled aluminum alloys, low casting and rolling speed, etc., to speed up casting and rolling speed, reduce downtime and time, The effect of avoiding the sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

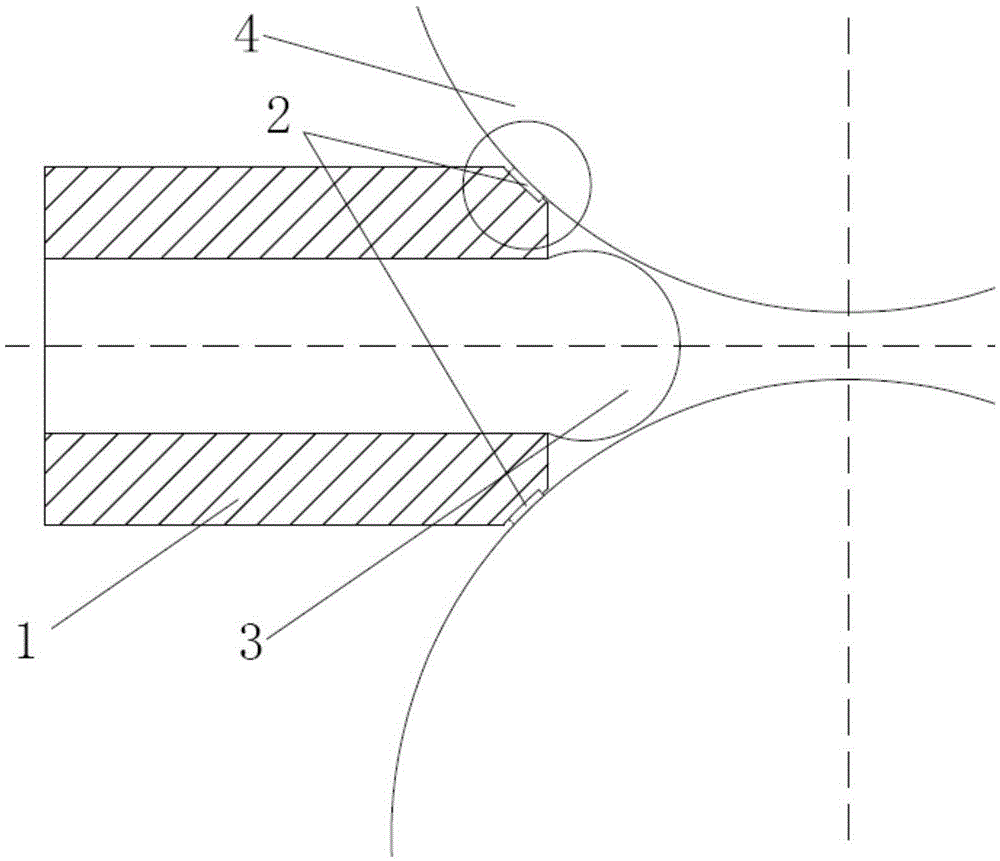

[0036] Such as figure 1 As shown, a high-speed aluminum alloy casting and rolling technology described in the present invention includes a nozzle 1 and a casting roll 4. When installed, the length of the casting area is 55 mm; the temperature of the molten aluminum in the front box is 690 ° C; the casting speed is 1.1 m / min; the cooling water temperature of the casting roll is 45°C, the cooling water pressure is 0.38MPa, the arc of the graphite block is 9°, the thickness of the graphite block is 15mm, and the height of the limit plate is 12mm.

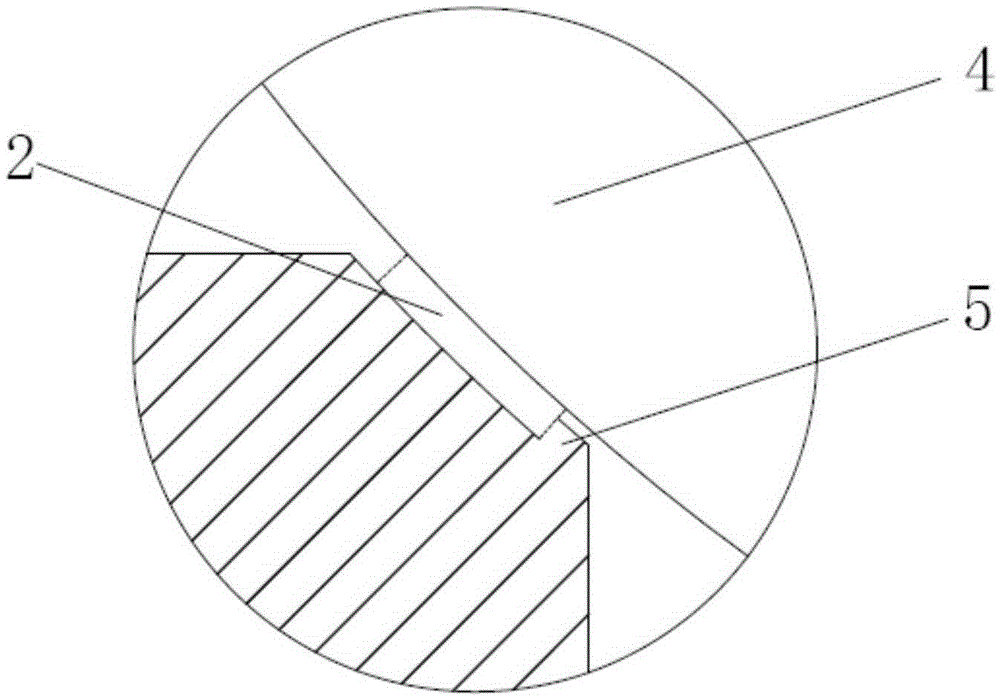

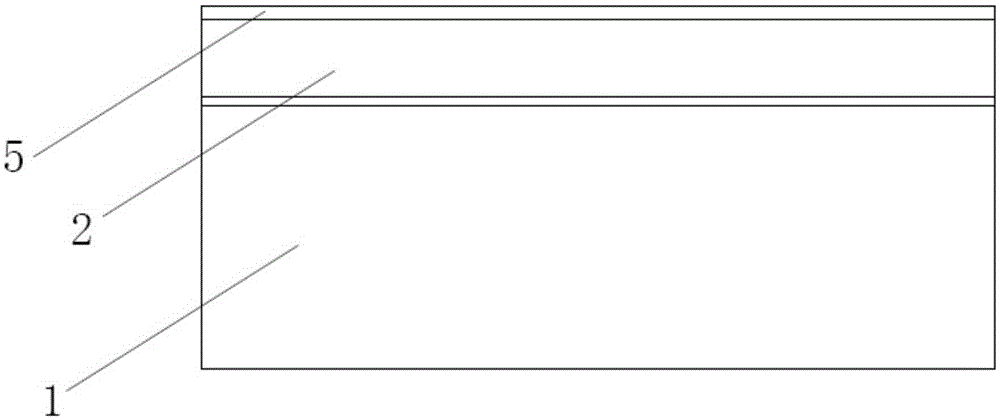

[0037] Such as Figure 1 to Figure 3 As shown, the graphite block 2 is in the shape of an arc, and is arranged at the upper and lower ends of the outlet of the nozzle 1, and a limit plate 5 is also arranged at the upper and lower ends of the outlet of the nozzle 1, and the limit plate 5 resists the graphite block 2 to prevent graphite Block 2 moves under the action of casting rolls 4 . The graphite block 2 is in contact with the cast...

Embodiment 2

[0043] During installation, the length of the casting and rolling area is 58mm; the temperature of the aluminum liquid in the front box is 700°C; the casting and rolling speed is 1.0m / min; the cooling water temperature of the casting roll is 48°C, and the cooling water pressure is 0.42MPa; the arc of the graphite block is 11° , the thickness of the graphite block is 13mm, and the height of the limiting plate is 10mm. All the other are with embodiment 1.

Embodiment 3

[0045]During installation, the length of the casting and rolling area is 63mm; the temperature of the aluminum liquid in the front box is 685°C; the casting and rolling speed is 1.15m / min; the cooling water temperature of the casting roll is 53°C, and the cooling water pressure is 0.36MPa; the arc of the graphite block is 16° , the thickness of the graphite block is 16mm, and the height of the limiting plate is 13mm. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com