Method for lowering powder size and changing powder shape in atomization process of molten metal

A metal melt and atomization process technology, applied in the field of powder metallurgy, can solve the problems of increased energy consumption, difficulty in obtaining flake powder, complicated technology, etc., and achieve the effect of reducing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

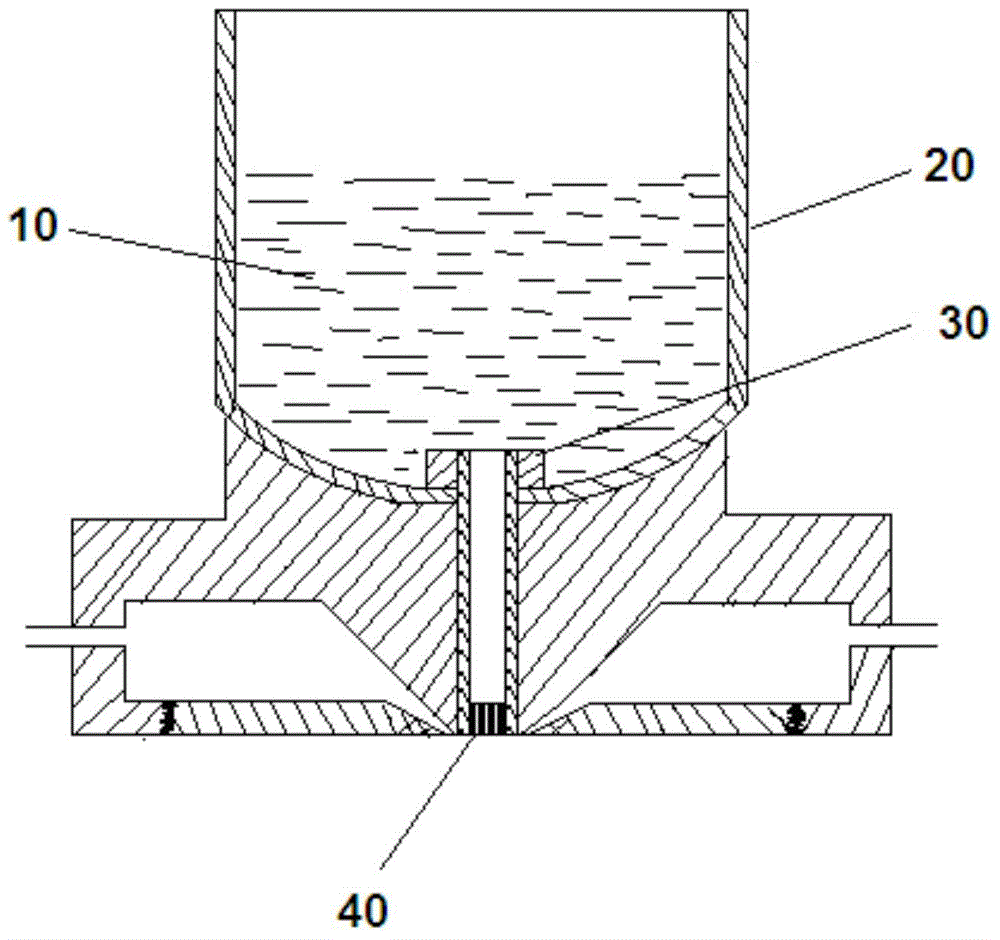

[0028] refer to figure 1 , an atomizing device for reducing the particle size of powder and changing the shape of powder during the atomization process of molten metal, comprising an intermediate leakage bag 20 and an atomization chamber for accommodating molten metal 10, the connection between the intermediate leakage bag 20 and the atomization chamber There is a leak nozzle 30 in between which allows the molten metal 10 to enter the atomization chamber from the middle leak bag 20. The leak nozzle 30 is provided with a leak nozzle head 40, and the leak nozzle head 40 is provided with one or more holes.

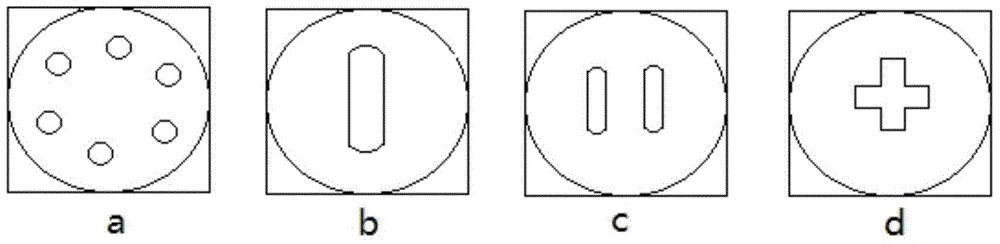

[0029] Described hole can be any shape, for example circle ( figure 2 a), rectangle ( figure 2 b, 2c), cross ( figure 2 d) etc.

[0030] use figure 2 The nozzle head 40 shown in a changes one hole of the original nozzle into 2-10 small holes without changing the area of the metal liquid flow column, and the diameter of the single-hole metal melt column becomes small...

Embodiment 2

[0031] Embodiment 2 prepares Sn powder

[0032] Sn powder is prepared by using the existing technology, using a pressure of 1.2Mpa and a flow rate of 8m 3 / min nitrogen gas, Sn powder is prepared through the annular nozzle, the hole diameter of the leak nozzle is 5mm, the flow rate of the molten metal is 15Kg / min, and the average particle size of the atomized powder is 80μm.

[0033] Also adopt the same pressure and flow nitrogen to prepare Sn powder through the annular nozzle, the flow rate of the molten metal is the same, and the nozzle head hole is changed from one hole in the prior art to 6 holes ( figure 2 a), the diameter of each small hole is 2.1 mm, and the average particle size of the atomized powder is 44 μm. This process greatly reduces the average particle size of Sn powder.

Embodiment 3

[0034] Embodiment 3 prepares stainless steel powder

[0035] The stainless steel powder is prepared by the existing technology, and the stainless steel powder is atomized by high-pressure water. The particle size is 30 μm.

[0036] Using high-pressure water with the same flow rate and the same pressure, using annular nozzles, the flow rate of the molten metal is 20kg / min, and the nozzle head hole is changed from one hole in the prior art to 5 holes, and the diameter of each small hole is 2.5mm. The average particle size of the powder is 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com