Manual welding device and method for barrel and mounting edge of thin-wall casing

A manual welding and thin-walled technology, which is applied in the direction of providing/removing protective gas devices, devices supporting electrode clamps, welding equipment, etc., can solve the problems of substandard welding quality and poor fit, so as to ensure welding quality and avoid Inappropriate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

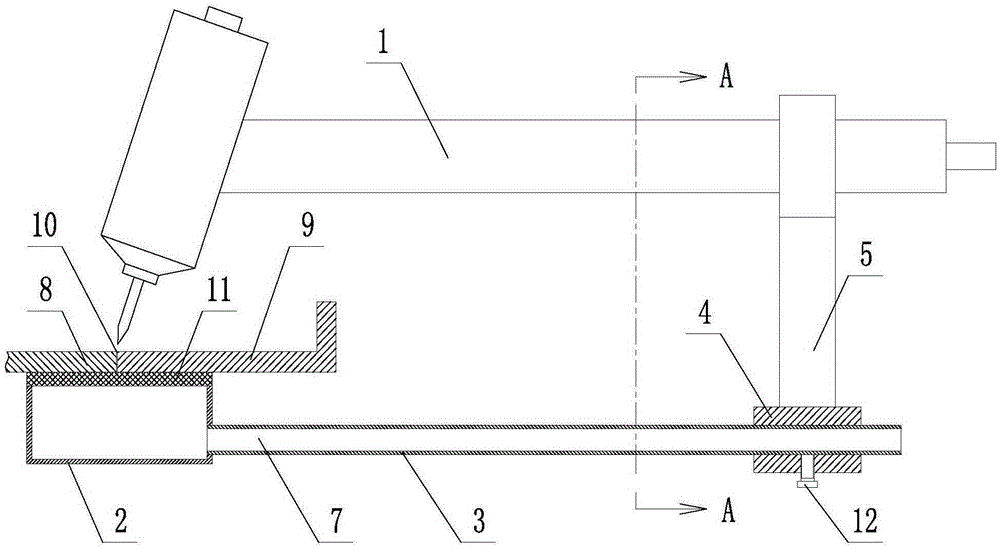

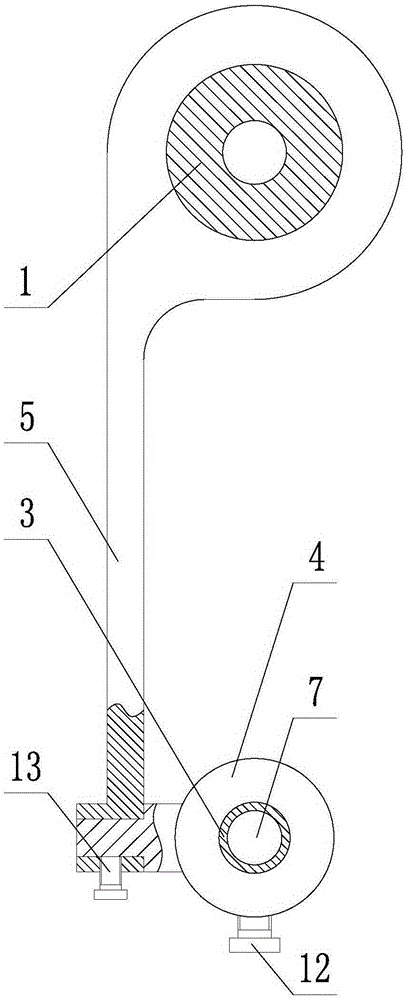

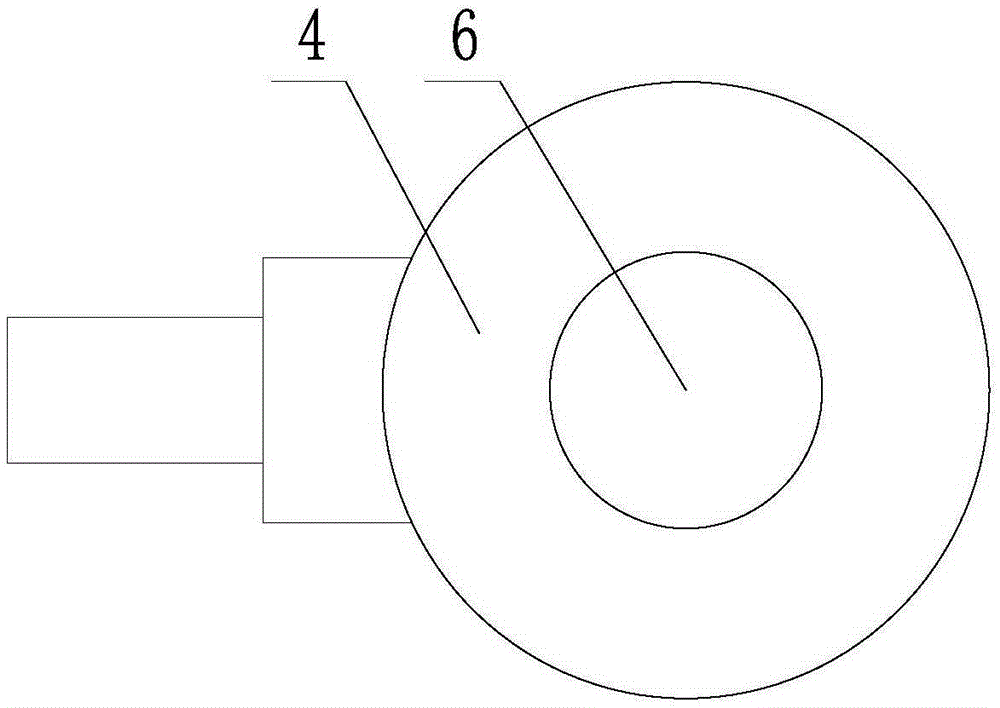

[0025] Such as figure 1 , 2 . As shown in 3, a manual welding device for a thin-walled casing body and an installation side, including a welding torch 1, a protective tow cover 2, a hollow pole 3, an adapter seat 4 and a connecting frame 5, one end of the connecting frame 5 Fixedly connected to the gun body of the welding torch 1, the other end of the connecting frame 5 is hinged on the adapter seat 4; a pole installation hole 6 is opened in the middle of the adapter seat 4, and one end of the hollow pole 3 is located on the pole installation In the hole 6, the other end of the hollow strut 3 is connected to the protective drag cover 2; the central hole of the hollow strut 3 is set as a vent hole 7, and one end of the vent hole 7 is connected with the argon gas source, and the other end of the vent hole 7 is connected with the argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com