Aluminum bar cutting and transporting device

A technology of transportation devices and aluminum rods, which is applied in metal processing and other directions, and can solve problems such as inconvenient transportation and manual measurement of dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

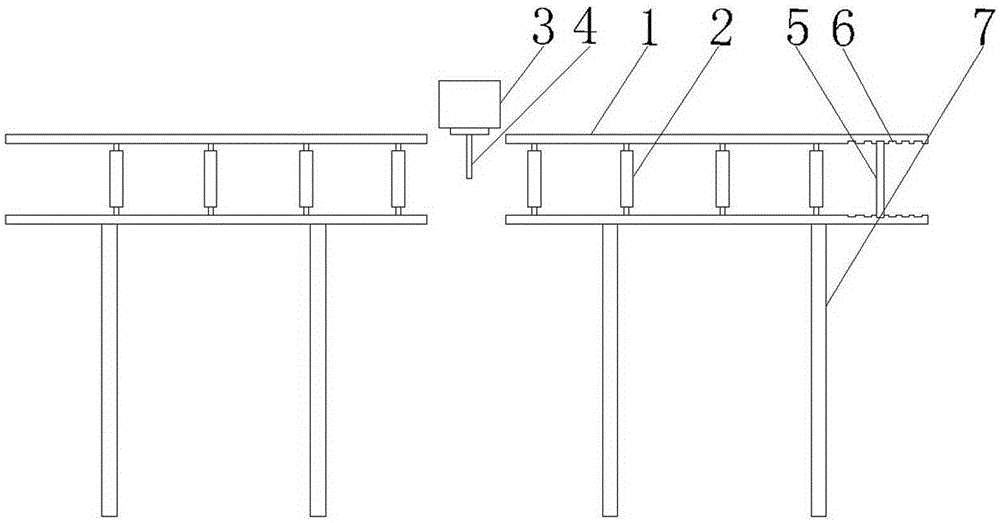

[0014] as attached figure 1 As shown, an aluminum bar cutting transportation device includes a conveying track 1 arranged on the same ground, and the conveying track includes a first conveying track and a second conveying track, and the first conveying track and the second conveying track are parallel to each other. A number of fixed rods are fixedly connected between the conveying tracks, the fixed rods are covered with bearings, and the outer surface of the bearings is fixedly connected with a drum 2, and the outer surface of the drum 2 is provided with bumps for anti-skid, wherein the first The upper end of one conveying track is higher than the drum 2, the upper end of the second conveying track is at the same level as the upper end of the drum 2, the middle part of the conveying track 1 is provided with an opening section for cutting sawtooth to pass through, and one end of the conveying track 1 is provided with The positioning plate 5 is arranged vertically downward, per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com