Multi-angle welding system based on welding engineering

A welding system and multi-angle technology, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive manual welding, the inability to realize multi-angle adjustment functions, and human body burns caused by sparks, etc., to reduce time-consuming and labor-intensive, Reduce the possible effect of sparks causing burns to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

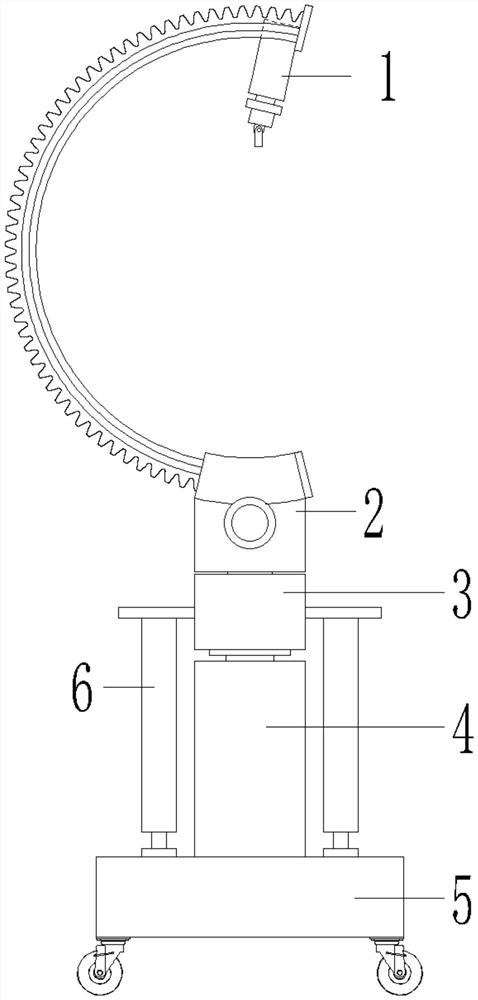

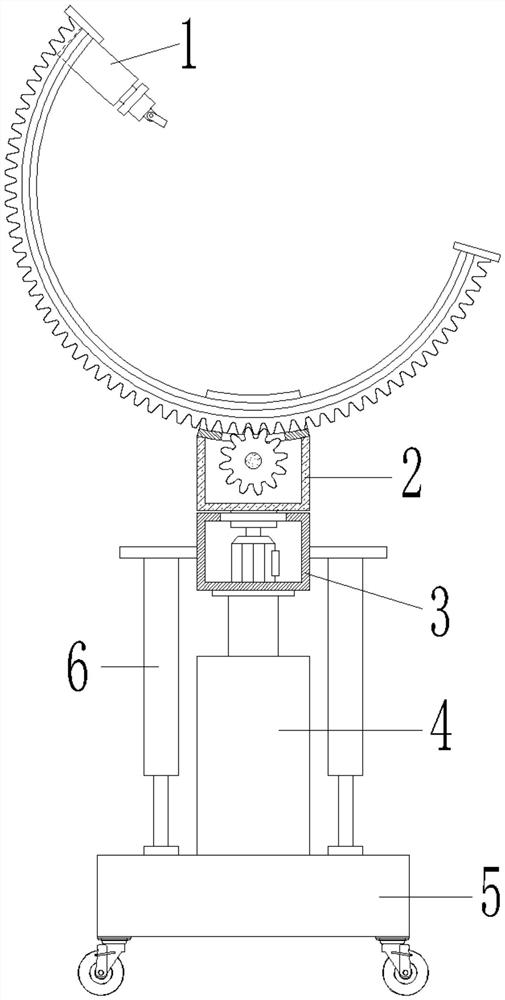

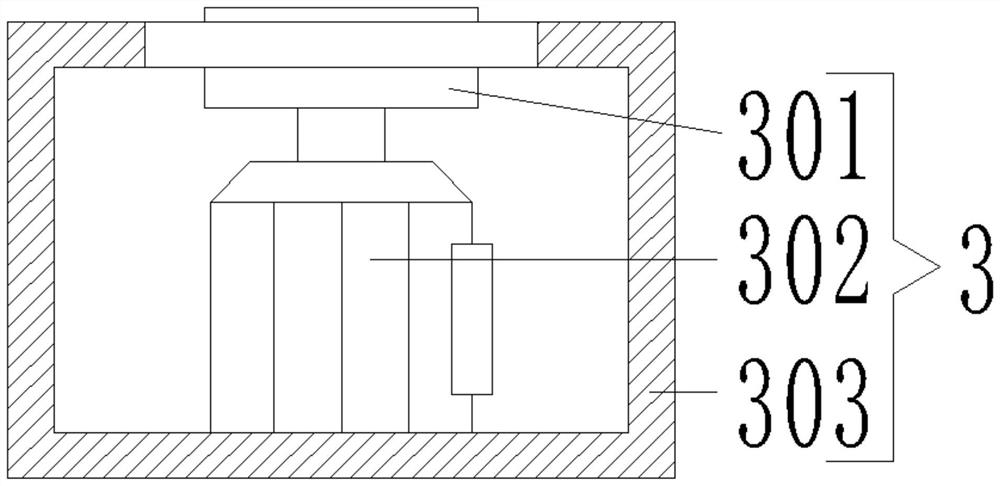

[0040] The following is attached Figure 1-8 The present invention is described in further detail.

[0041] An embodiment provided by the present invention: a multi-angle welding system based on welding engineering, including a multi-angle welding device, a single-chip controller 7 and a navigation system 8. The mobile unit 5, the vertical lift adjustment unit 4, the 360°rotation adjustment unit 3, the warp adjustment unit 2 and the welding unit 1 are composed, and the vertical lift adjustment unit 4 is connected between the carrying mobile unit 5 and the 360° rotation adjustment unit 3 , the warp adjustment unit 2 is connected to the top of the 360° rotation adjustment unit 3, and the welding unit 1 is connected to the end of the warp adjustment unit 2; the vertical lift adjustment unit 4 is the first electronically controlled telescopic rod, which can be adjusted by 360° rotation The left and right sides of the unit 3 are all provided with a stabilizing mechanism 6 (refer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com