Positioning mechanism for automobile membrane baking

A technology of positioning mechanism and baking film, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of inconsistent surface curvature, poor versatility, and complex adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

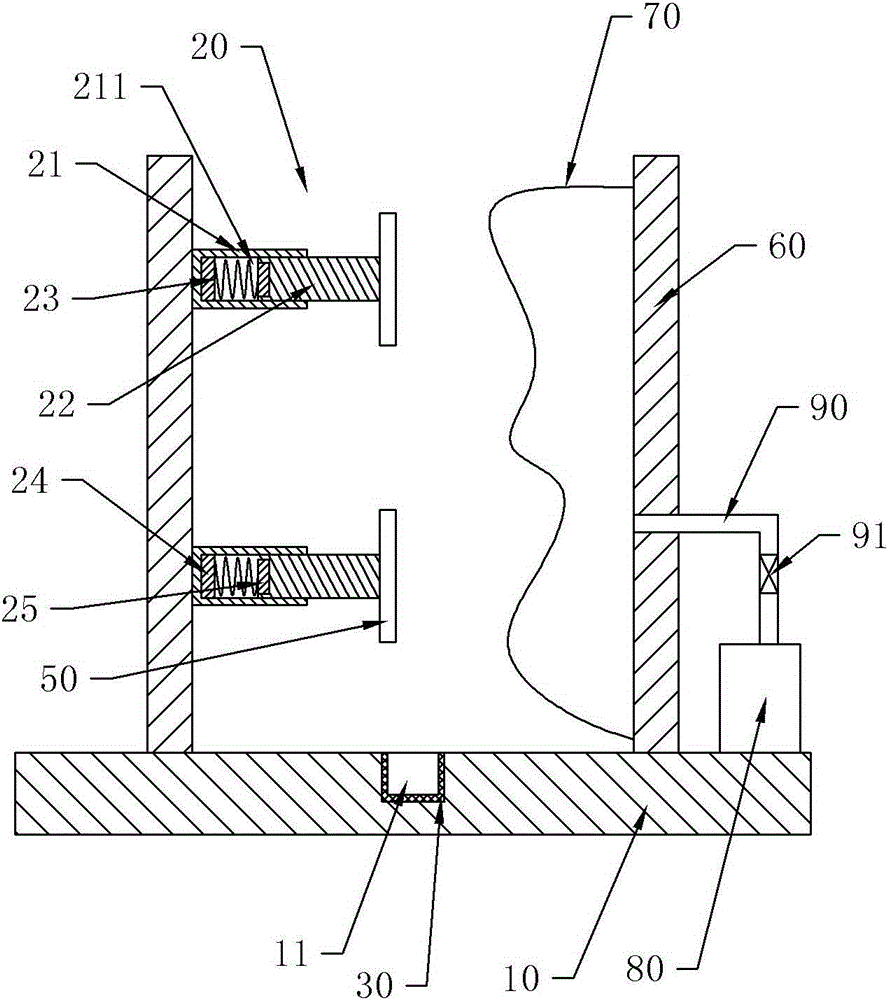

[0020] Embodiment 1 is basically as attached figure 1 Shown: a positioning mechanism for automobile baking film, including a base, a number of positioning grooves are provided on the base to match the insertion of one end of the automobile glass, and buffer pads are provided in the positioning grooves. When the car glass is placed in the positioning groove, the force on the lower end of the car glass is relatively large, which is easy to cause wear and tear. The buffer pad in the positioning groove can slow down the force on the lower end of the car glass, thereby reducing wear. The base is also provided with a first positioning unit and a second positioning unit, the first positioning unit includes a positioning frame and a number of positioning seats connected to the positioning frame, each positioning seat offers a sliding hole, and each sliding hole has a A push rod is slidably connected, and the push rod is connected to the bottom of the sliding hole through an elastic me...

Embodiment 2

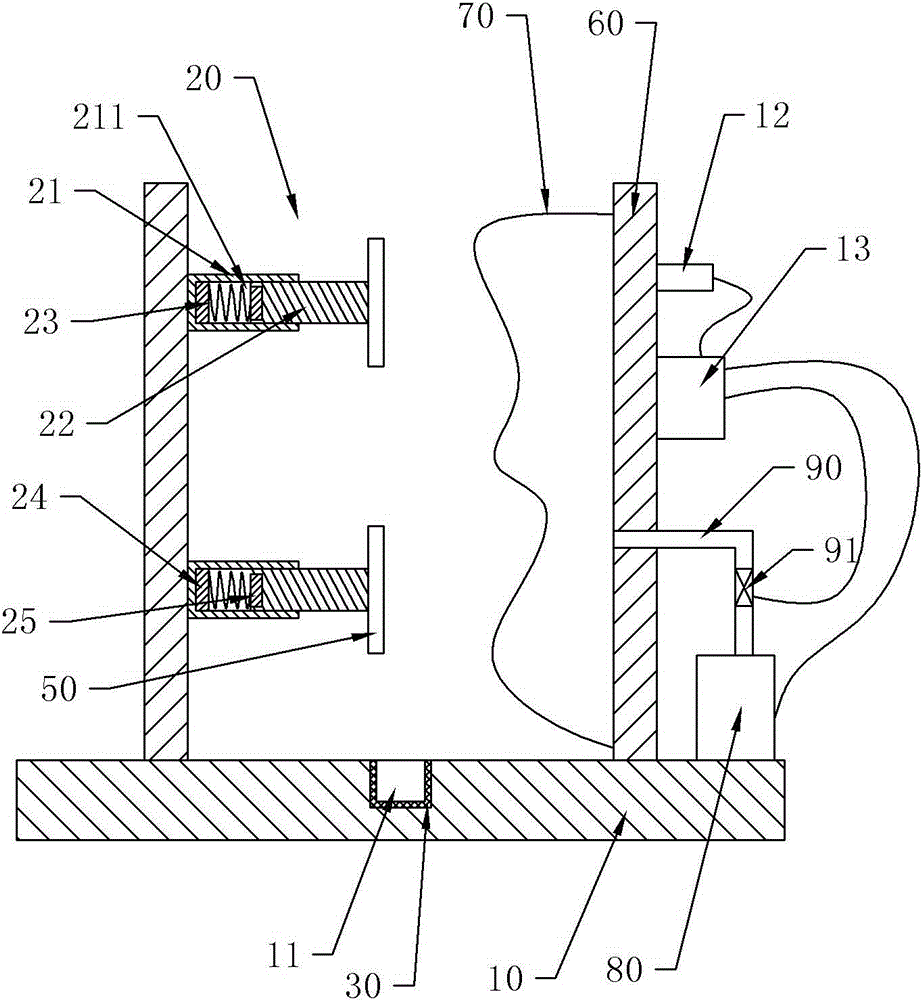

[0024] Such as figure 2 As shown, the difference from Embodiment 1 is that this embodiment also includes a controller and a pressure sensor for detecting the pressure in the airbag body, the valve is an electronically controlled valve, and the pressure sensor, the electronically controlled valve and the air pump are all connected with the control valve. electrical connection. The pressure sensor can detect the pressure in the airbag in real time. When the pressure detected by the pressure sensor reaches the upper limit set by the controller, the controller controls the inflator to stop and at the same time controls the electronic control valve to close, so that the pressure in the airbag can be guaranteed. , so that the airbag body is in the state of positioning the automobile glass.

[0025] Specific working principle:

[0026] Take embodiment 1 as an example to describe in detail below: figure 1 As shown, in specific use, first place the car glass to be baked in the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com