Female-male slider demoulding, detection and packaging integrated device for plastic gloves

A slider-type, all-in-one technology, used in packaging, gloves, packaging protection, etc., can solve the problems of difficult product quality control, high labor costs, low production efficiency, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

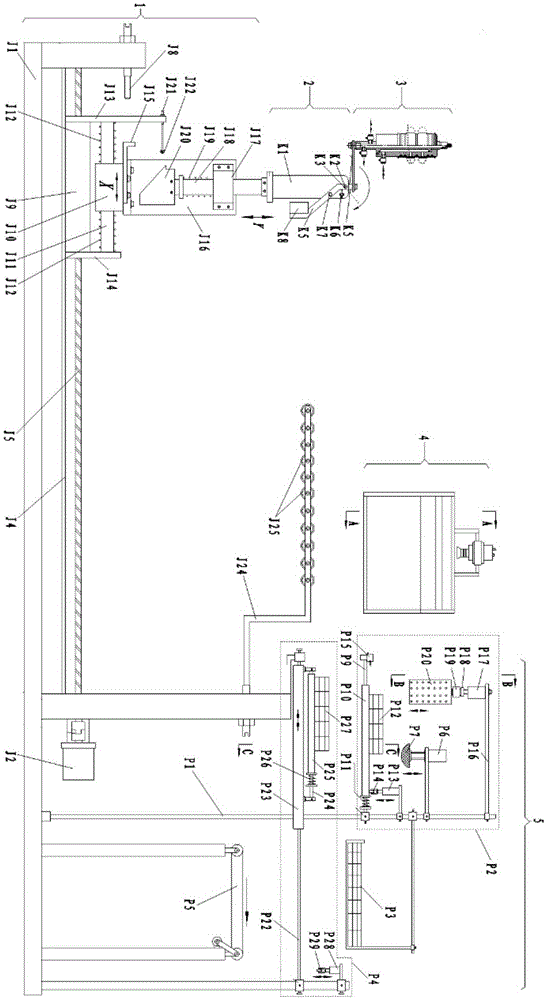

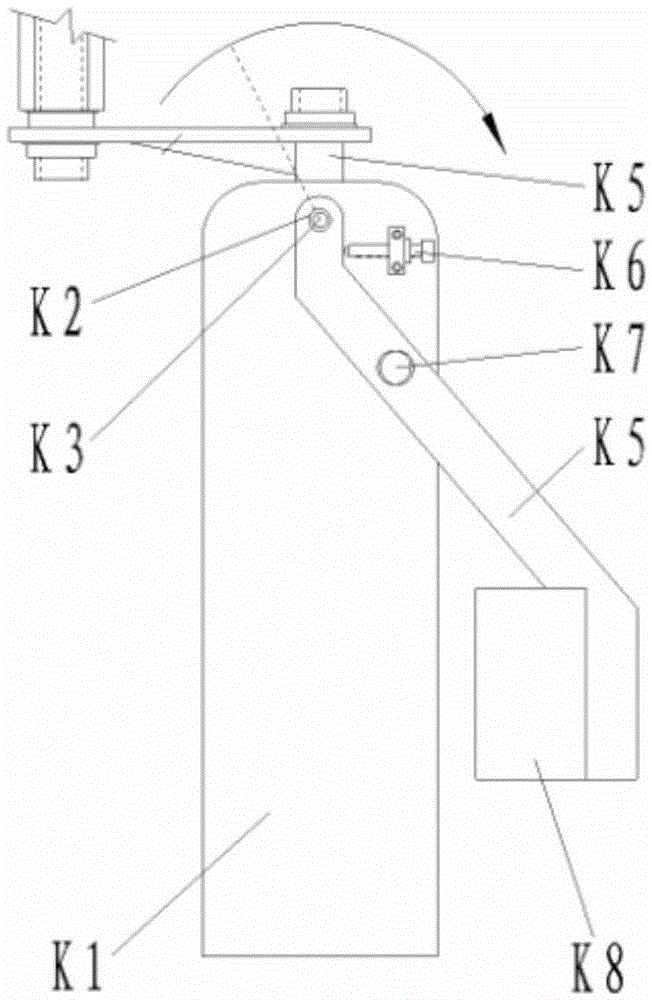

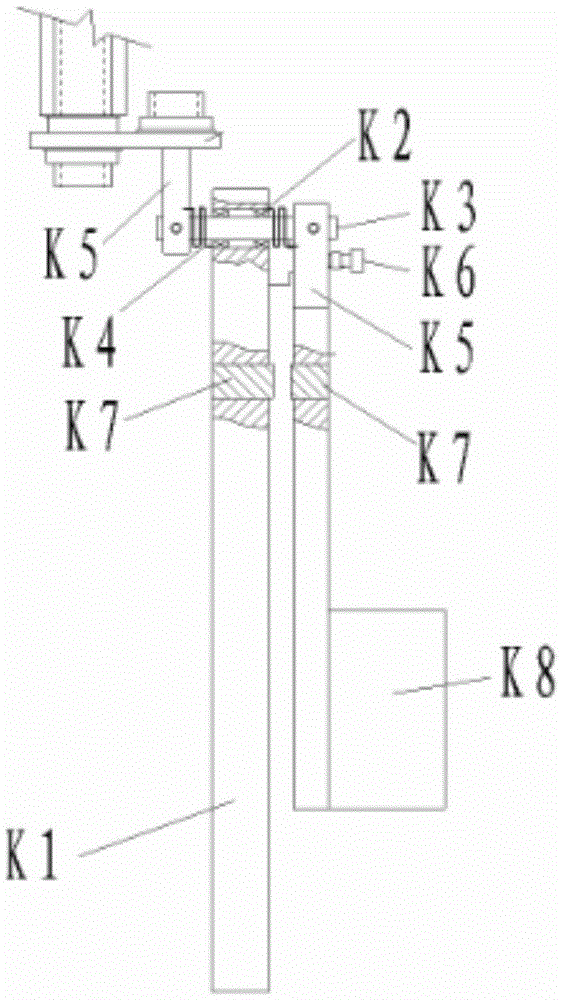

[0032] like figure 1 As shown, the present invention is an all-in-one machine for demoulding, detecting and packaging plastic gloves with a sliding block, including a handling manipulator 1, a rotating swing frame 2, a demoulding head 3, a camera detection table 4, and a sorting machine for removing sleeves 5, and a rotating swing frame 2 is fixedly connected to the transport manipulator 1, the demoulding head 3 is set on the rotating pendulum 2, the camera detection table 4 is set on the upper right of the transport manipulator 1, and the stripping sorting machine 5 is placed on the right side of the transport manipulator 1.

[0033]Handling manipulator 1 includes machine base J1, driving motor J2, X-axis guide rail J4, X-axis screw rod J5, X-axis left ejector rod J8, X-axis female slider J9, X-axis sub-slider J10, X-axis sub-guide rod J11 , sub-slider return spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com