Ceiling fault surface structure of urban rail stainless steel vehicle

A stainless steel and vehicle technology, applied in the field of urban rail stainless steel vehicle roof section structure, can solve the problems of reduced production efficiency, large welding volume, unstable height difference, etc., to simplify the production process, reduce material costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

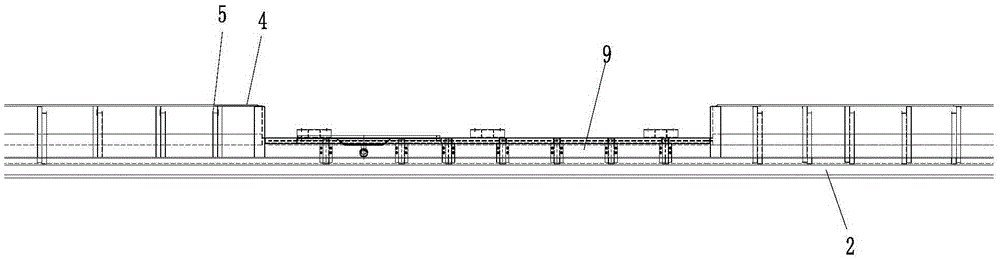

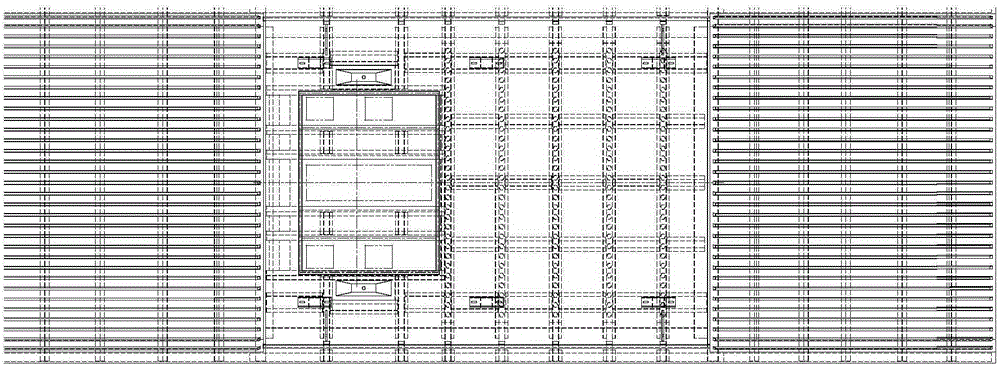

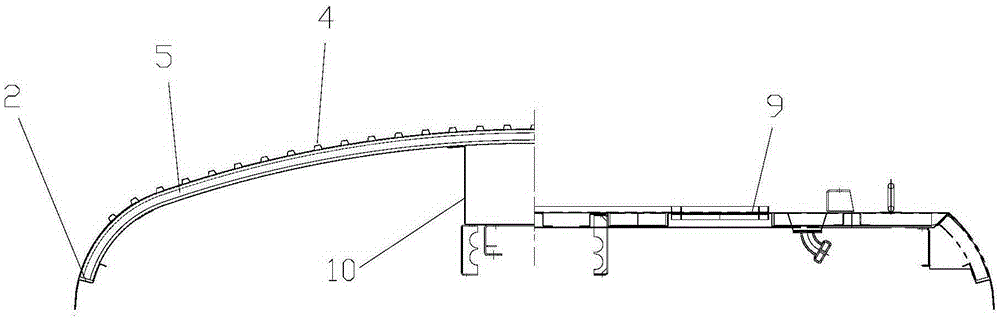

[0024] Attached below figure 1 to attach Figure 13 To further illustrate the present invention, the urban rail stainless steel vehicle roof steel structure includes two upper string beams 2 and a plurality of curved beams 5 arranged transversely to the upper string beams 2 and spaced in parallel. On the surface 12, the top surfaces of the two ends of the curved beam 5 are engaged with the side roof 1 respectively, and the middle top surface of the curved beam 5 is provided with a covering surface, and the covering surface is composed of the corrugated plate area and the arc plate area to form the same plane, and the corrugated plate area and the arc plate The areas are connected by arc welding, and the air-conditioning platform 9 is set in the arc plate area; the top surface of the corrugated plate area and the top surface of the arc plate area are on the same plane. That is to say, the amount of connecting small parts in the corrugated plate area and the arc plate area is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com