Quantitative feeding device for aluminum electrolytic cell

An aluminum electrolytic cell and feeding device technology, which is applied to conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of increased production resource consumption, production material consumption, and reduced service life of production equipment, so as to reduce pollution. The effect of improving the amount of material, improving the service life and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

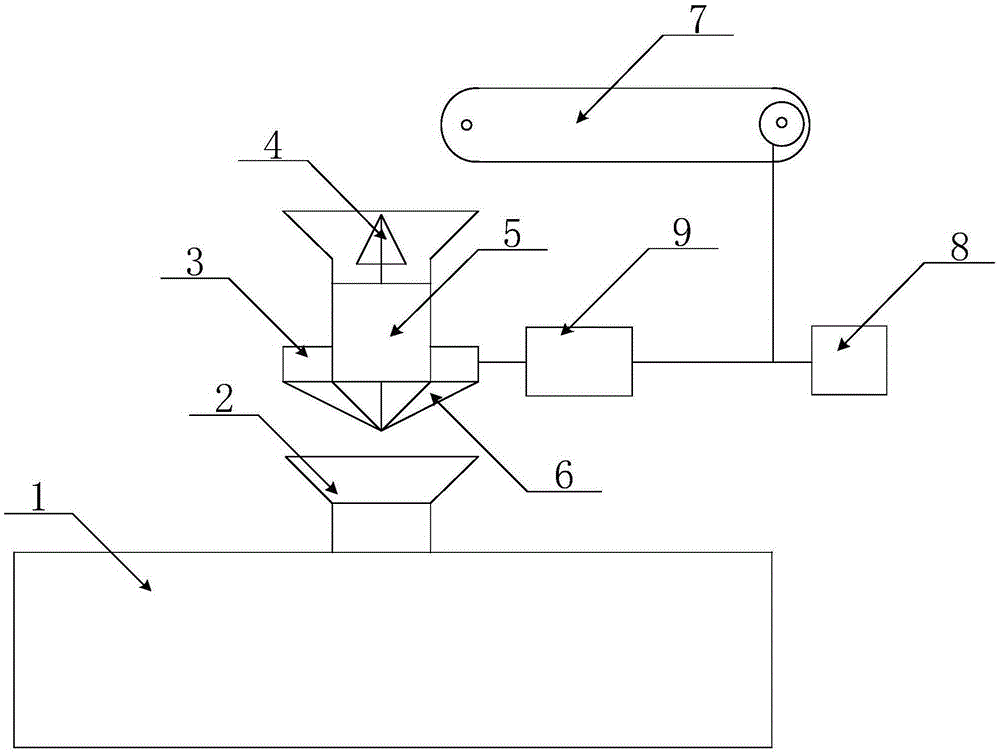

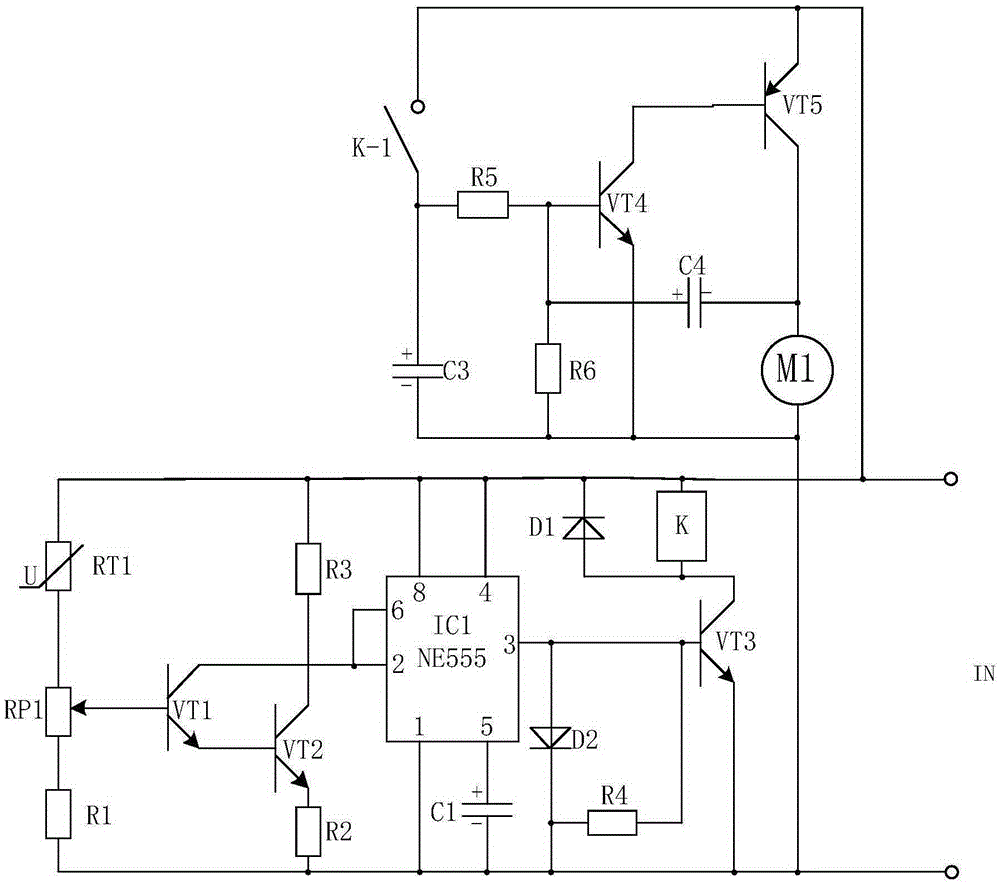

[0017] Such as figure 1 As shown, the aluminum electrolytic cell quantitative feeding device includes a feeding device 5 arranged directly above the electrolytic cell hopper 2 of the aluminum electrolytic cell 1, a feeding transmission device 7 arranged above the feeding device 5, and simultaneously with the feeding device 5 and the feeding device 5. The power supply 8 connected to the feeding transmission device 7; the blanking device 5 includes a hopper, a rotary weighing cone 6 arranged at the bottom of the hopper, and a blanking device that is arranged on the outside of the hopper and is connected to the rotary weighing cone 6 and the power supply 8 respectively. The motor 3 is also provided with an anti-accumulation cone 4 on the unloading hopper, and a pressure-sensitive time-delay control circuit 9 is also provided between the power supply 8 and the unloading motor 3 .

[0018] When working, the feeding transmission device sends the material into the unloading device. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com