A semi-automatic filling and stoppering machine

A stoppering machine, a semi-automatic technology, applied in the direction of packaging, sealing plugs, bottle filling, etc., can solve the problems of inconvenient operation, long cycle, large volume, etc., to achieve the convenience of installation, maintenance and debugging, convenience of manual bagging, and improvement of production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

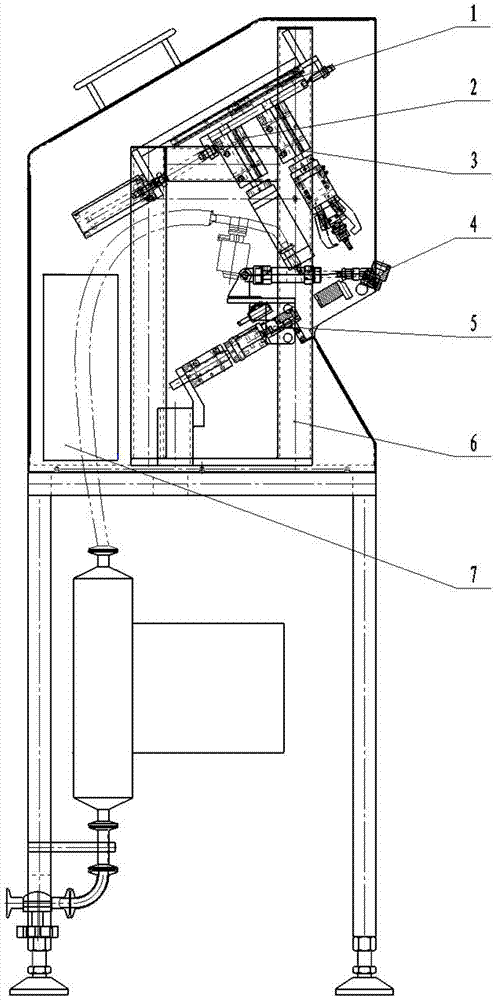

[0033] like figure 1 As shown, a semi-automatic filling and corking machine of the present invention includes a frame assembly 6, an electrical control assembly 7, a moving assembly 1, a plug feeding and turning assembly 4, and a clamp assembly 5 are installed on the frame assembly 6, and the filling assembly 2 and 3 parts of the plugging group are fixedly connected vertically with the moving assembly 1, and the moving assembly 1 and the fixture assembly 5 are arranged in parallel. Unlike the vertical filling and plugging methods of the prior art, the semi-automatic filling provided by the present invention When the stoppering machine is working, the direction of the soft bag is inclined to the horizontal plane.

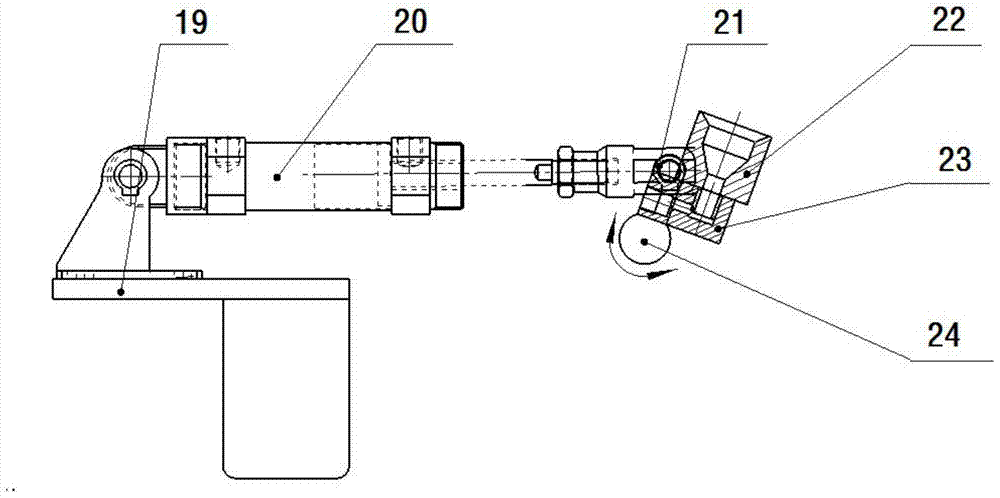

[0034] The working process of the present invention is as follows: the plug 47 is manually placed on the cover pipe 22 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com