Filling machine bottle conveying device

A conveying device and filling machine technology, applied in liquid bottling, bottle filling, packaging, etc., can solve problems such as heavy load, high motor power requirements, and difficult reversing of bottle clamping plates, so as to reduce load and improve conveying Efficiency and speed, and the effect of simplifying the structure of the manipulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

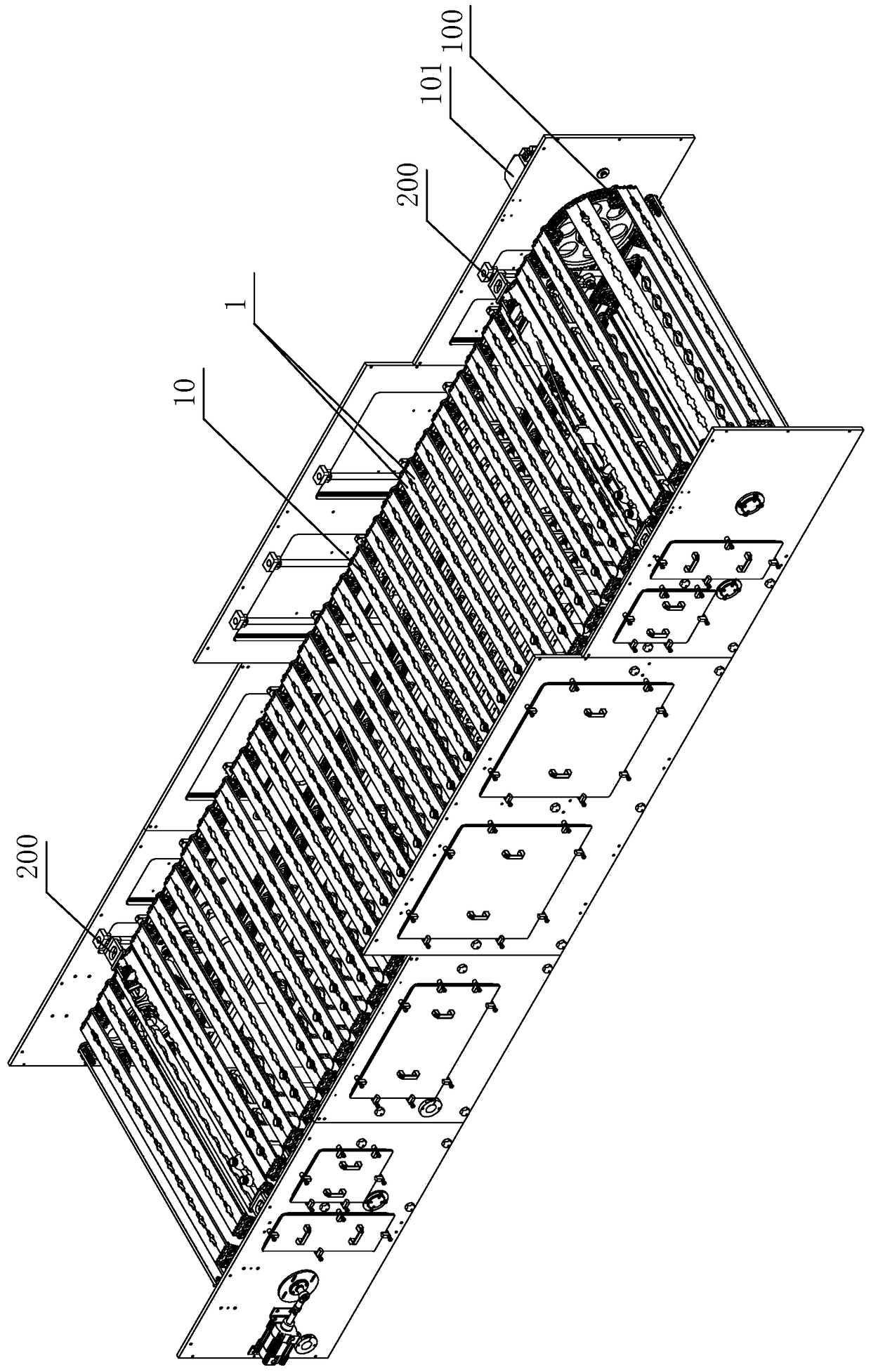

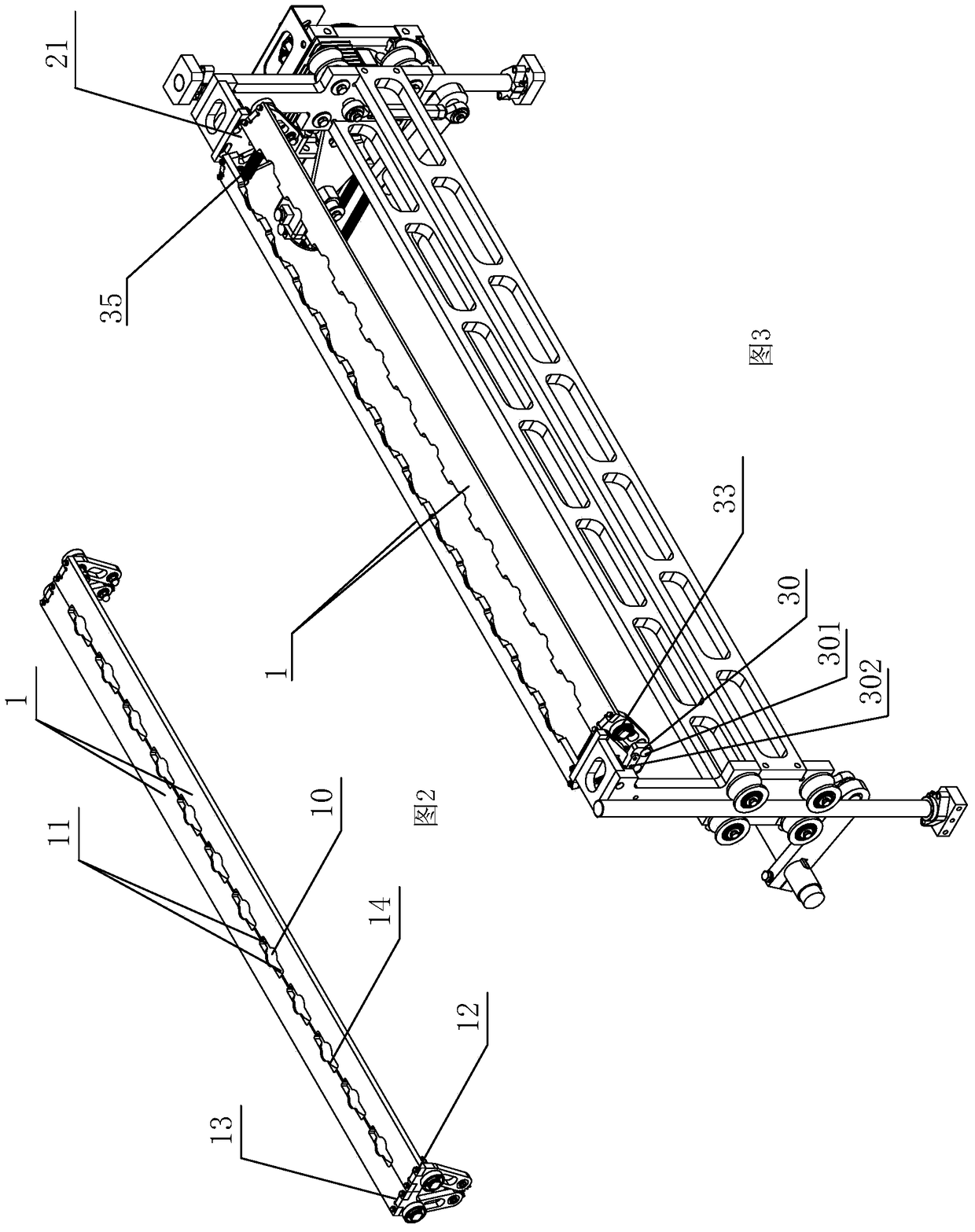

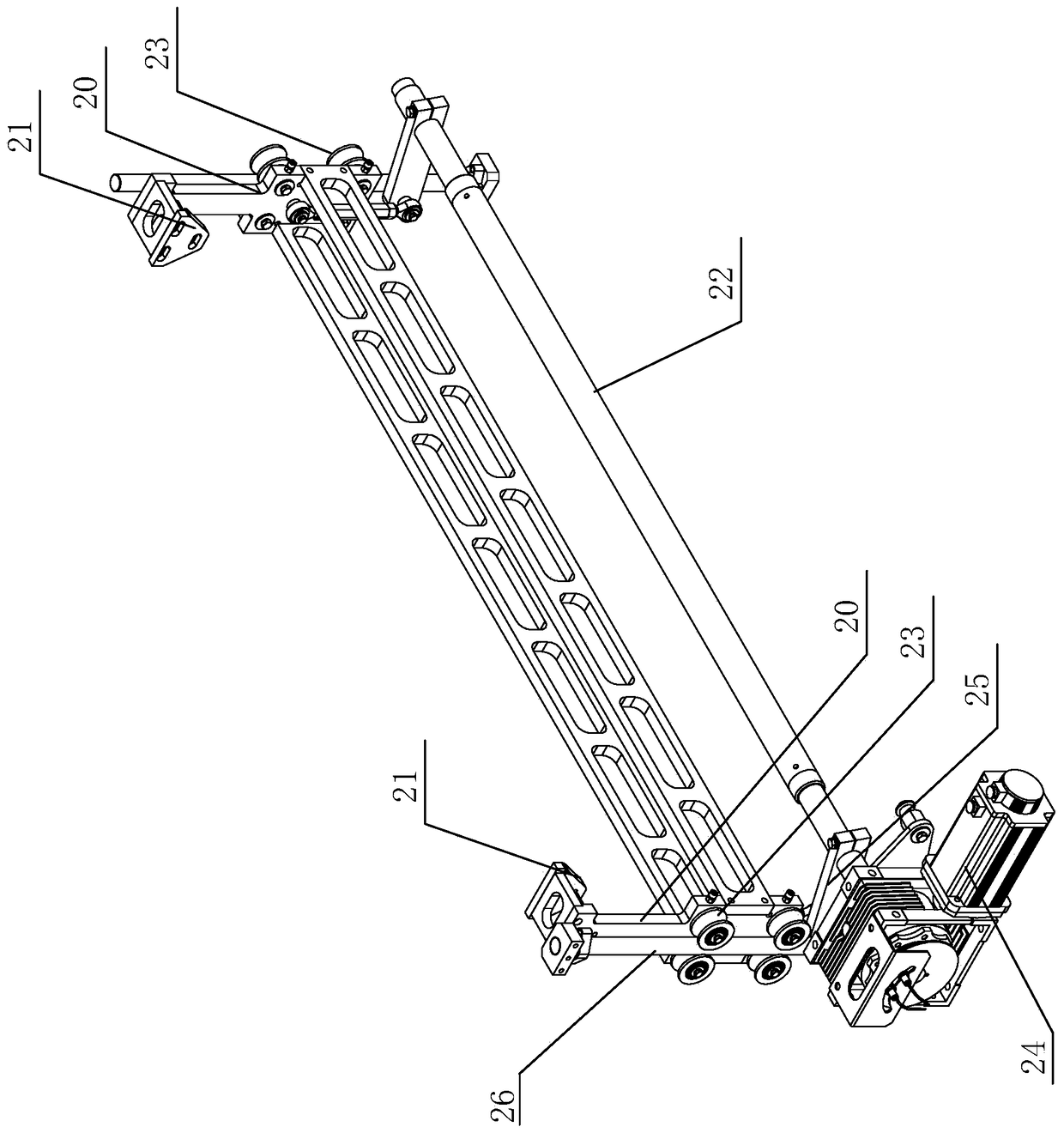

[0021] Refer to attached picture. The bottle conveying device of the filling machine provided by the present invention includes multiple pairs of bottle clamping parts 1, each pair of bottle clamping parts can be opened and has a plurality of openable and closable bottle clamping ports 10, and the bottle conveying device also includes a chain cycle conveying Mechanism, chain circulation conveying mechanism is driven by motor 101.

[0022] The paired bottle clamping parts 1 are installed on the conveyor chain 100 of the chain circulation conveying mechanism through the opening and closing module mechanism, and the opening and closing action is performed on the chain circulation conveying mechanism. Take it out from the conveying chain and then open and close, which reduces the action, simplifies the equipment, and improves the speed, and can realize the following V-shaped opening action, with faster speed and simpler structure.

[0023] The opening and closing module mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com