Method for producing continuous high-efficiency nano fibre nonwoven fabric and production device thereof

A nanofiber, nonwoven technology, applied in nonwovens, fiber processing, fiber chemical characteristics, etc., can solve the problems of uneven distribution of fibers, low production efficiency, etc., to improve spinning efficiency, improve quality, reduce The effect of electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

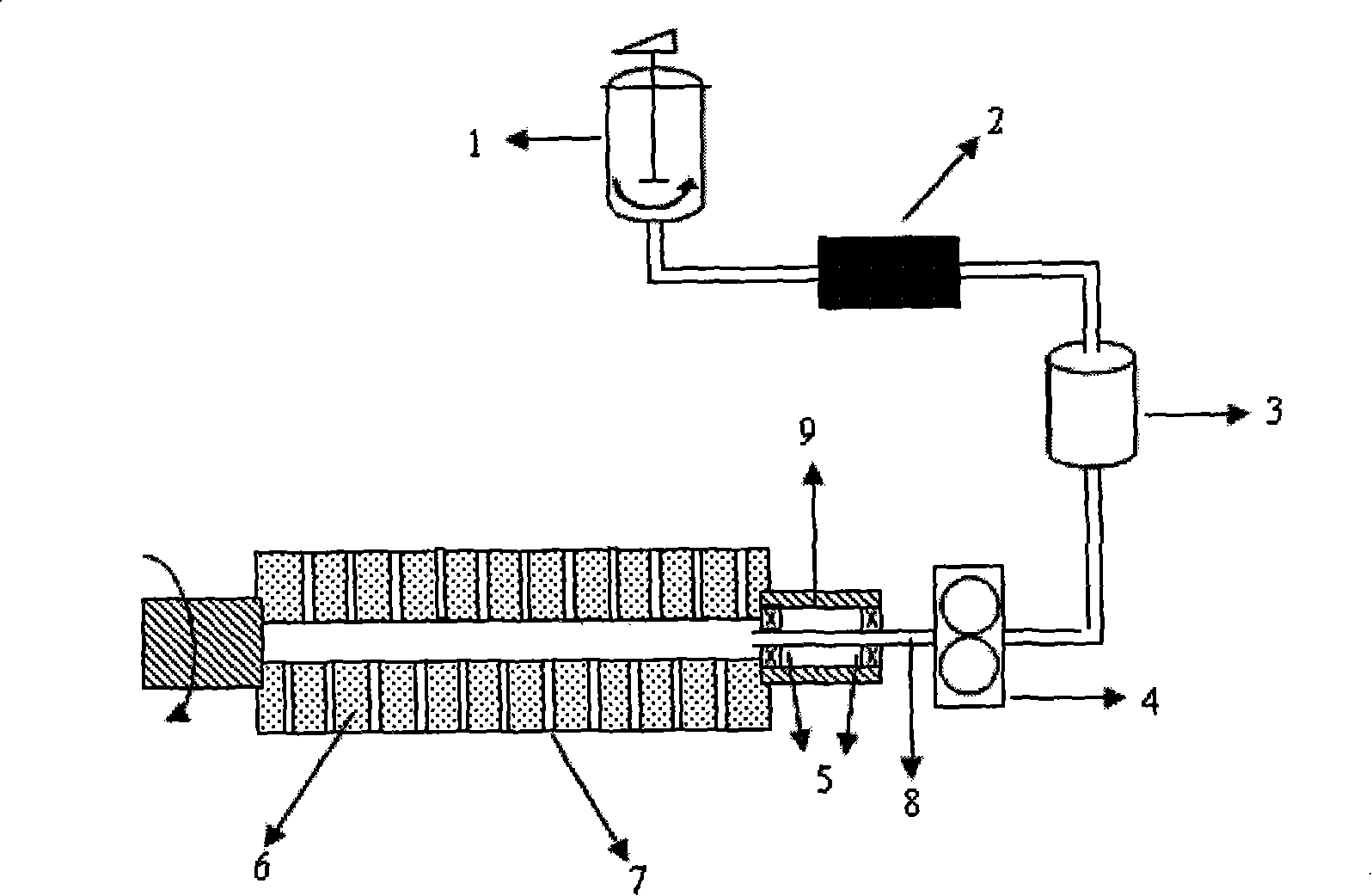

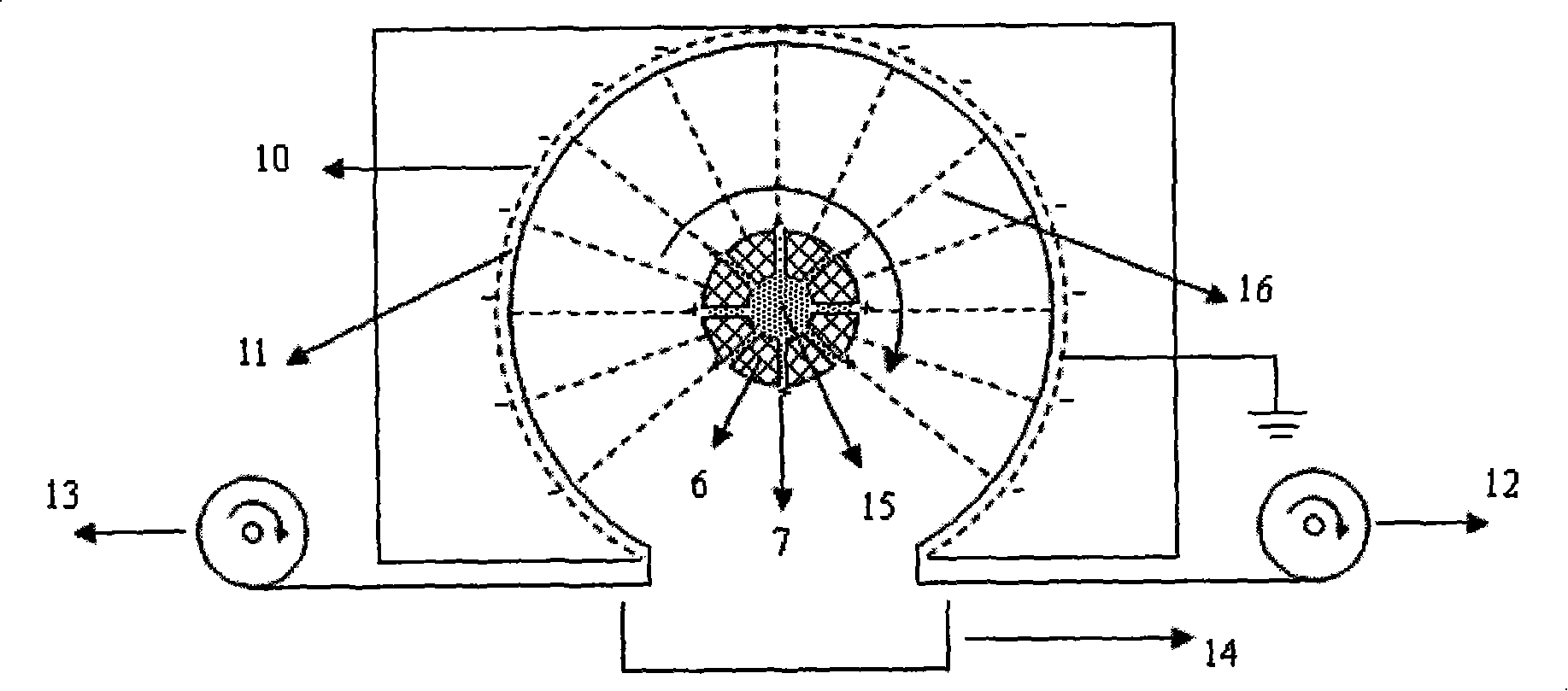

[0037] Weigh 52.6g of polyvinyl alcohol 1750 and dissolve it in 1000ml of deionized water, add appropriate amount of sodium chloride and citric acid to make a transparent polymer spinning solution 15 with a mass concentration of 5% without precipitation. The metering pump 4 advances the spinning solution 15 to the metal drum 6 at 11 L / h. The length of the metal drum 6 is 50 cm, the outer diameter is 5 cm, the inner diameter is 3.5 cm, and the rotating speed is 2 r / min. The diameter of the capillary 7 on the metal drum 6 is 1.5 cm. mm, such as Figure 4As shown, the distribution pattern of capillary pores 7 is a twill pattern, and the number of pores is 48. The distance between the positive and negative electrodes is 40cm, and the applied voltage is 40KV. According to the above-mentioned implementation steps, the nanofiber nonwoven fabric is prepared, the fiber diameter distribution is between 390-670nm, and the average output is 21g / h.

Embodiment 2

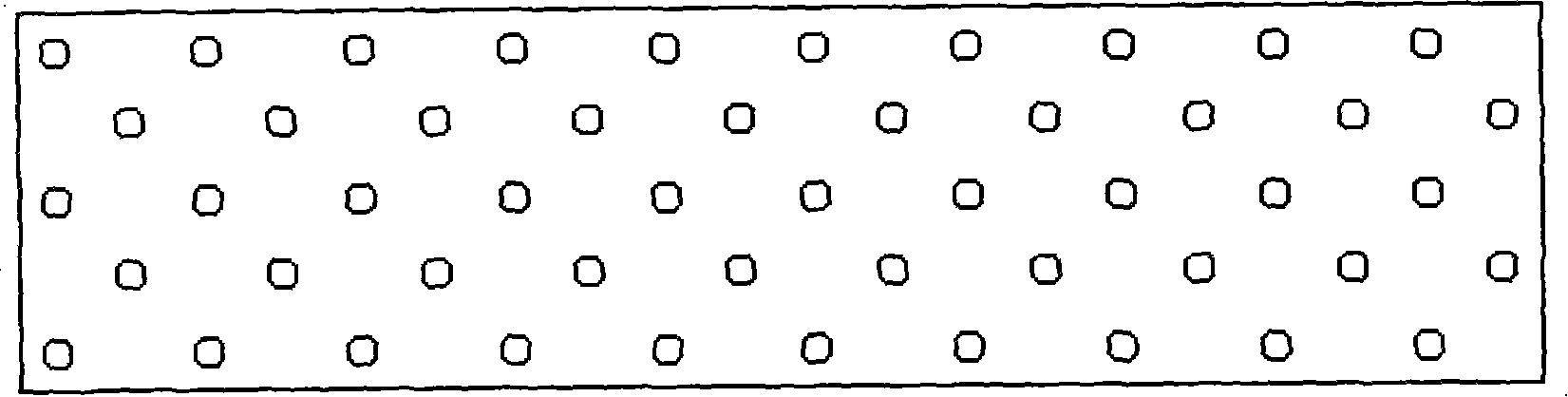

[0039] Weigh 87g of polyvinyl alcohol 1750 and dissolve it in 1000ml of deionized water, add appropriate amount of sodium chloride and citric acid to prepare a transparent polymer spinning solution 15 with a mass concentration of 8% without precipitation. The metering pump 4 advances the spinning solution 15 to the metal drum 6 at 12 L / h. The length of the metal drum 6 is 50 cm, the outer diameter is 5 cm, the inner diameter is 3.5 cm, and the rotating speed is 4 r / min. The diameter of the capillary hole 7 on the metal drum 6 is 1.5 cm. mm, such as image 3 As shown, the distribution pattern of capillary pores 7 is plain pattern, and the number of pores is 69. The distance between the positive and negative electrodes is 30cm, and the applied voltage is 54KV. According to the above implementation steps, the nanofiber nonwoven fabric is prepared, the fiber diameter distribution is between 320-610nm, and the average output is 28g / h.

Embodiment 3

[0041] Dissolve 63.8 g of polyethylene oxide (molecular weight: 1 million) in 1000 ml of deionized water, and stir in water at normal temperature to prepare a transparent polymer spinning solution 15 with a mass concentration of 6% without precipitation. The metering pump 4 advances the spinning solution 15 to the metal drum 6 at 12 L / h. The length of the metal drum 6 is 50 cm, the outer diameter is 5 cm, the inner diameter is 3.5 cm, and the rotating speed is 3 r / min. The diameter of the capillary hole 7 on the metal drum 6 is 1.5 cm. mm, such as Figure 5 As shown, the distribution pattern of capillary pores 7 is a satin pattern, and the number of pores is 32. The distance between the positive and negative electrodes is 30cm, and the applied voltage is 50KV. According to the above implementation steps, the nanofiber nonwoven fabric is prepared, the fiber diameter distribution is between 230-580nm, and the average output is 18g / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com