Loom equipment with broken yarn recognition function

A technology of broken yarn identification and loom, which is applied in looms, textiles, textiles and papermaking, etc., to achieve the effects of short loom preparation time, easy positioning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

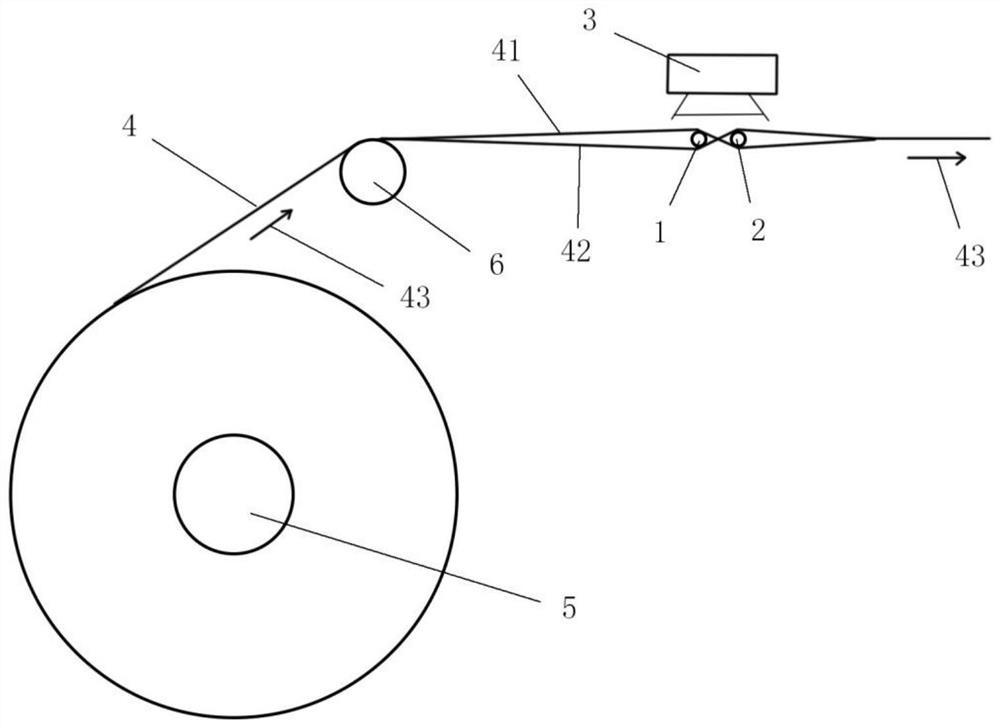

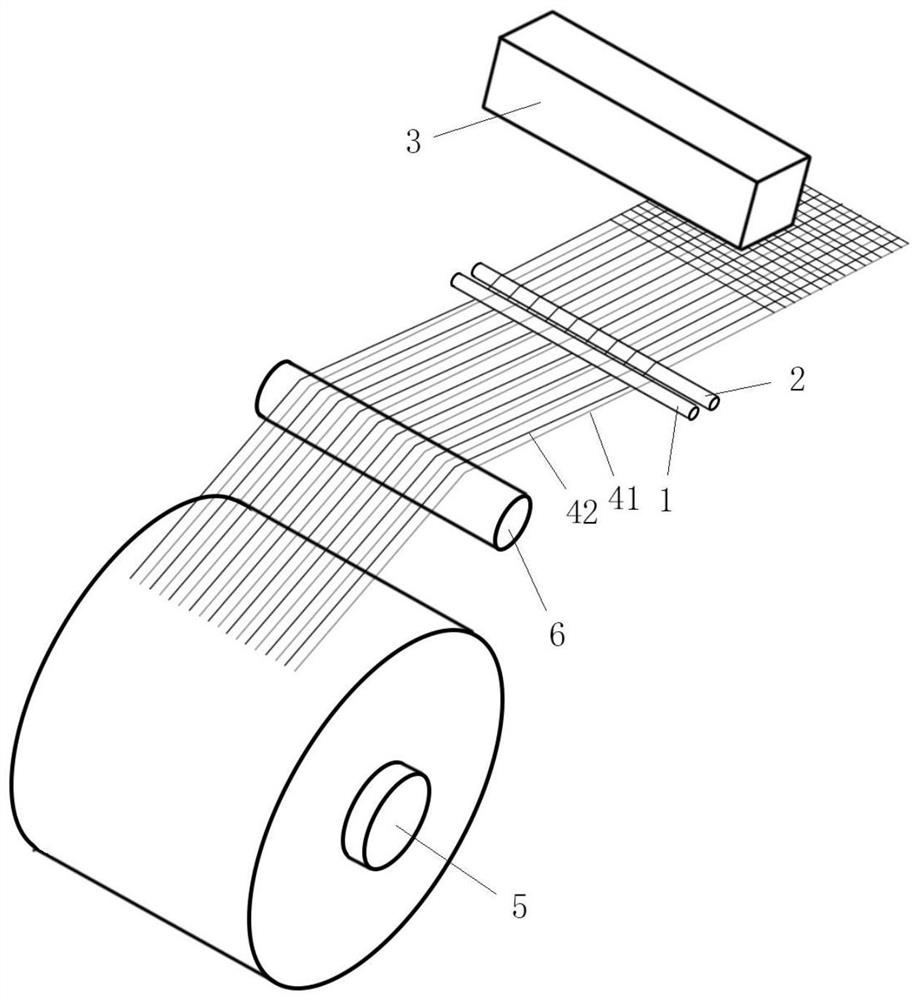

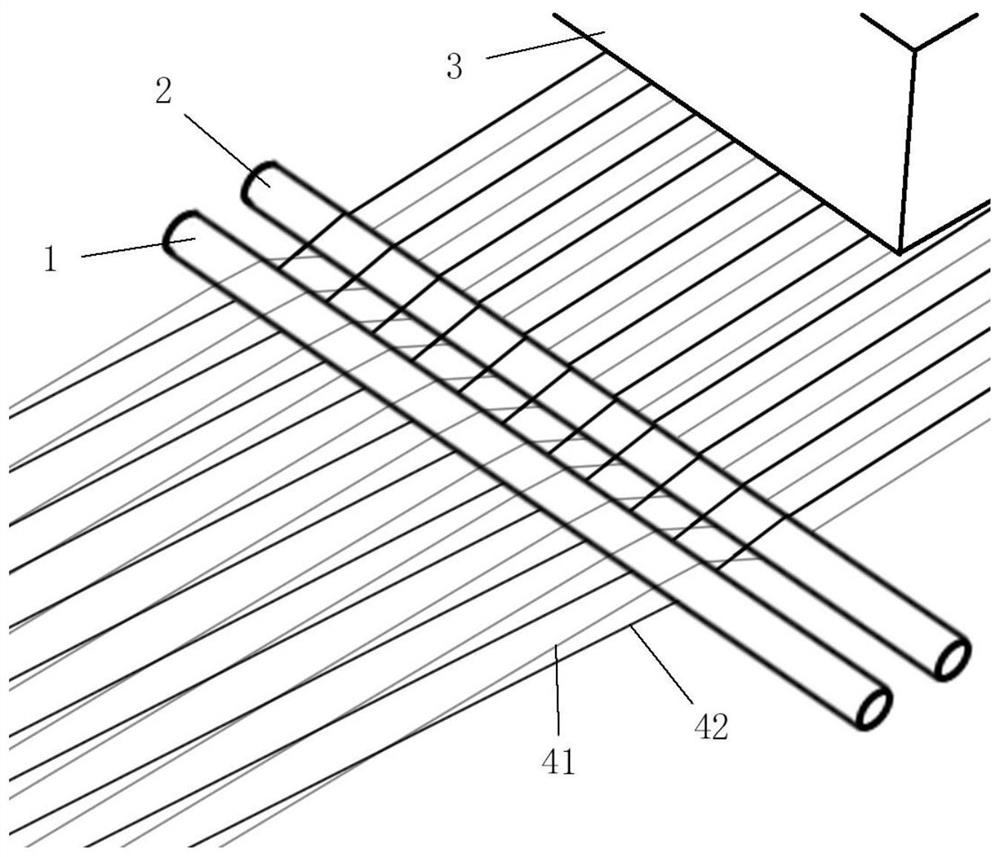

[0024] see Figure 1 to Figure 6 , figure 1 A schematic diagram of the side view structure of the loom equipment with broken yarn recognition provided in the embodiment of the present application; figure 2 A schematic diagram of the three-dimensional structure of the loom equipment with broken yarn recognition provided in the embodiment of the present application; image 3 A schematic diagram of the partial structure of the loom equipment with broken yarn recognition provided in the embodiment of the present application at the position of the two yarn dividing rollers; Figure 4 Schematic diagram of images captured by the image recognition device for loom equipment with broken yarn recognition provided in the embodiment of the present application; Figure 5 A schematic diagram of the image captured by the image recognition device when a warp yarn breaks in the loom equipment with broken yarn recognition provided in the embodiment of the present application; Image 6 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com