Low-energy-consumption membrane bioreactor and sewage treatment method

A membrane bioreactor and membrane bioreaction technology, applied in aerobic and anaerobic processes, can solve the kinetic energy consumption of membrane gas flushing, does not solve the coupling between membrane tank and biochemical reaction tank, and requires biochemical aeration and liquid circulation Pump energy consumption and other issues, to achieve a significant effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

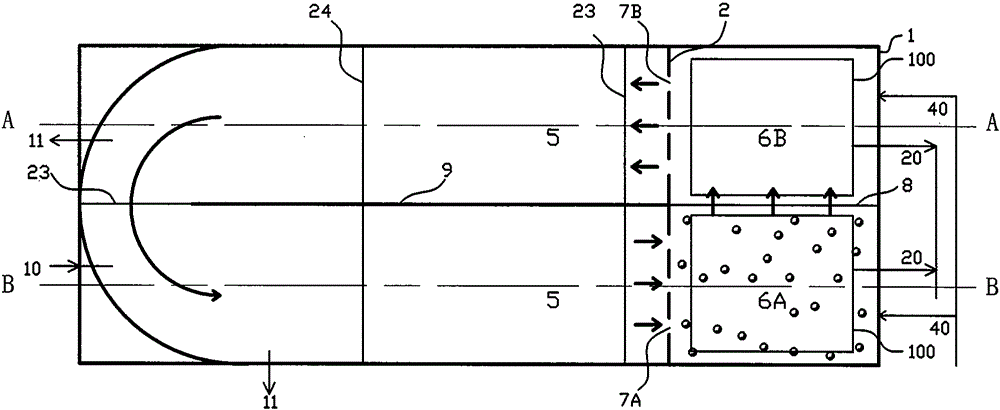

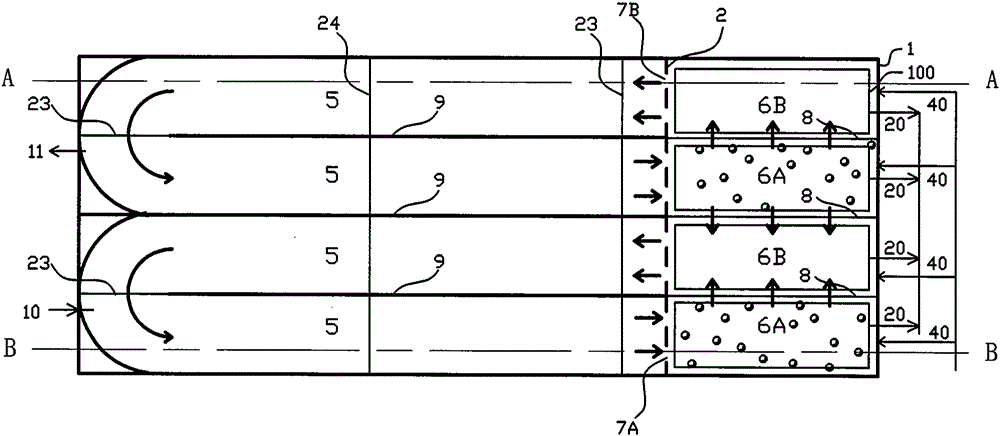

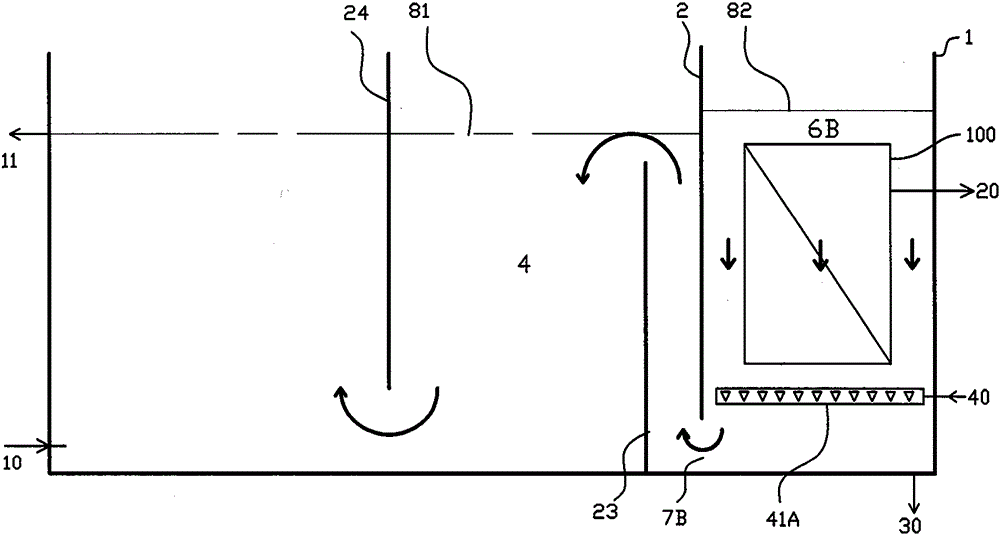

[0026] see Figure 1 to Figure 7 , the first to fourth low energy consumption membrane bioreactors are characterized in that they include a reaction tank (1), at least one vertical partition (2) is arranged in the reaction tank (1), and the partition (2) will The reaction pool (1) is divided into a reaction zone (4) and a membrane pool (6), and at least one vertical membrane pool partition (8) is vertically arranged with the vertical partition (2) in the membrane pool (6) , the membrane pool partition (8) separates the membrane pool (6) into equal membrane pool A (6A) and membrane pool B (6B), and the top of the membrane pool partition (8) is significantly lower than the top of the reaction pool (1) , at least one membrane module (100) is respectively provided in the middle of membrane pool A (6A) and membrane pool B (6B); There is at least one communication channel A (7A); at least one communication channel B (7B) is provided at the bottom of the partition (2) to communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com