Wastewater-free reverse osmosis water generator

A technology of reverse osmosis and water making machine, which is applied in osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problem of poor pure water quality, electricity consumption, RO membrane Short life and other problems, to achieve the effect of reducing the TDS value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

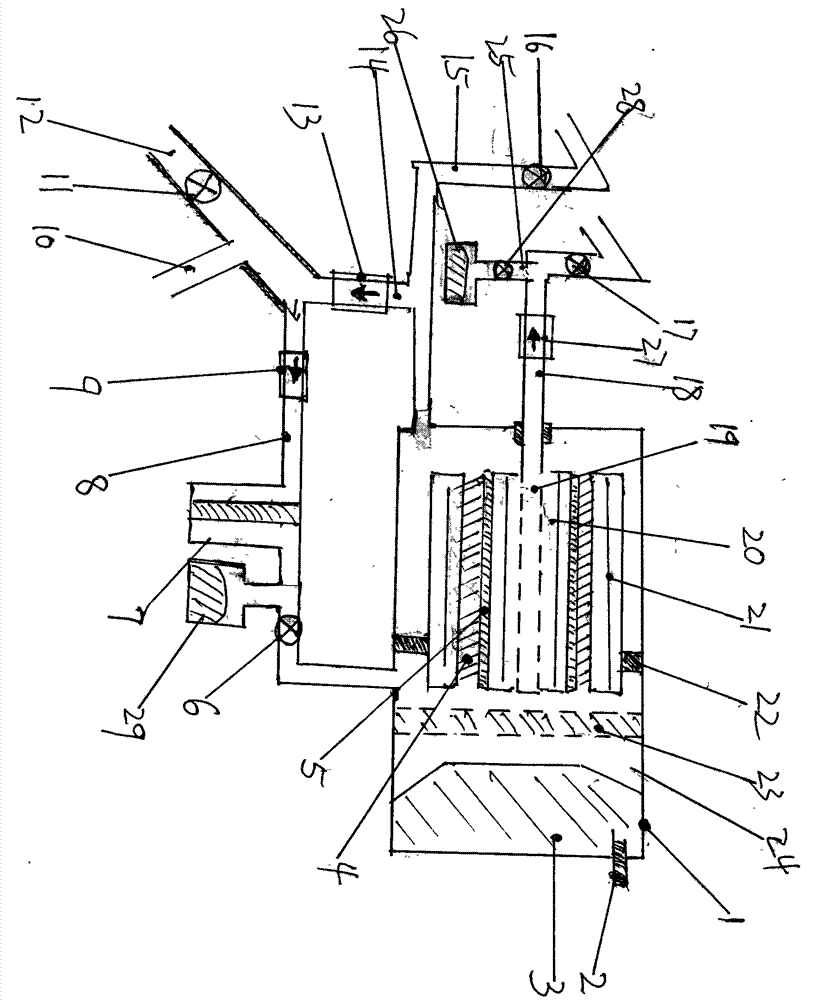

[0010] figure 1 The shown wastewater-free reverse osmosis water generator of the present invention is composed of a primary filtration group 7 and an RO membrane group 24. There is a spacer 21 inside the RO diaphragm 20, and a plurality of RO diaphragms 20 communicate with the pure water collection pipe 19 and wrap around them. Wrap pure water collection pipe 19, RO diaphragm 20 has grid 5, RO outer rubber ring 22 is sealed with membrane shell 1, the concentrated water outlet end of membrane shell 1 is connected with concentrated water outlet pipe 15 and its concentrated water outlet switch 16 , the pure water collection pipe 19 is connected to the pure water outlet pipe 18 and its pure water outlet switch 17, the water inlet pipe 8 is connected to the membrane shell 1, the concentrated water outlet pipe 15 is divided into the return water pipe 14, and the return water pipe 14 has a return water one-way Valve 13, according to the flow direction of the total water inlet, the wa...

Embodiment approach 2

[0013] figure 1 The shown wastewater-free reverse osmosis water generator of the present invention consists of a primary filter group, RO membrane group, and a pure water pressure storage tank. The RO membrane group 24 is connected to the concentrated water outlet pipe 15 and its concentrated water outlet switch 16 and pure water. Water outlet pipe 18 and its pure water outlet switch 17, pure water outlet pipe 18 connects the pressure tank pure water pipe 25 and connects the pure water pressure water storage tank 26, according to the pure water outlet water flow direction, the pure water before the pressure tank pure water pipe 25 There is a pure water check valve 27 on the water outlet pipe 18; the concentrated water outlet pipe 15 is divided into a return pipe 14, and there is a return water check valve 13 on the return pipe 14. After adjusting the valve 11, other water pipes 10 and water inlet pipes 8 are separated. There is a water inlet check valve 9 on the water inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com