Treatment process of colored sewage in the production of purple sweet potato flour

A treatment process, a technology of purple potato powder, is applied in the field of organic wastewater treatment technology to achieve the effects of reducing difficulty, being beneficial to transportation and preservation, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

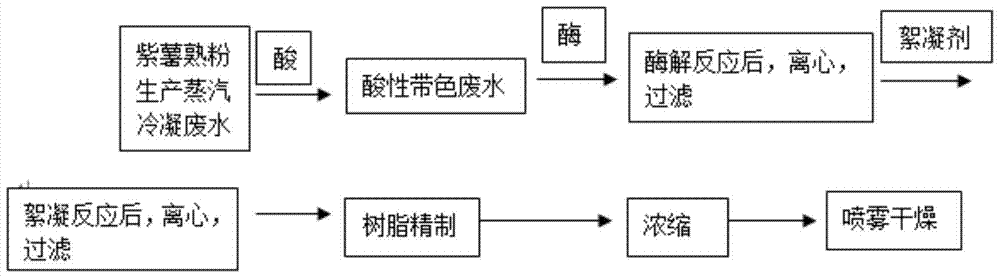

[0031] Such as figure 1 Shown, the treatment process of colored sewage in the production of purple sweet potato powder is characterized in that, specifically comprises the following steps:

[0032] (1) Enzymolysis reaction: Add citric acid solution to steam condensation wastewater from the production of cooked purple potato powder, adjust the pH value to 3-5, and provide a suitable pH environment for the subsequent enzymolysis reaction. When the temperature drops to 45°C, Using the heat of steam cooking can effectively save the energy consumption of enzymatic hydrolysis reaction. Add 0.6% pectinase to the mixture and react for 1 hour. The enzymatic hydrolysis reaction can decompose pectin, protein, starch and other organic substances in colored wastewater. ingredients, making the product clarity and transparency improved;

[0033] (2) Centrifugation: place the mixture in a centrifuge to control the rotational speed to 3500rpm / min, centrifuge for 5-10 minutes, remove the granu...

Embodiment 2

[0040] Such as figure 1 Shown, the treatment process of colored sewage in the production of purple sweet potato powder is characterized in that, specifically comprises the following steps:

[0041] (1) Enzymolysis reaction: add hydrochloric acid solution to the steam condensation wastewater from the production of cooked purple potato powder, adjust the pH value to 3-5, and provide a suitable pH environment for the subsequent enzymolysis reaction. When the temperature drops to 45°C, use The heat during steam cooking can effectively save the energy consumption of the enzymatic hydrolysis reaction. Add 1% amylase to the mixture and react for 2 hours. The enzymatic hydrolysis reaction can decompose organic components such as pectin, protein, and starch in the colored wastewater. Improve product clarity and transparency;

[0042] (2) Centrifugation: place the mixture in a centrifuge to control the rotating speed to 3500rpm / min, centrifuge for 5 minutes, remove the granular impurit...

Embodiment 3

[0049] Such as figure 1 Shown, the treatment process of colored sewage in the production of purple sweet potato powder is characterized in that, specifically comprises the following steps:

[0050] (1) Enzymolysis reaction: add sulfuric acid solution to the steam condensation wastewater from the production of cooked purple potato powder, adjust the pH value to 3-5, and provide a suitable pH environment for the subsequent enzymolysis reaction. When the temperature drops to 60°C, use The heat during steam cooking can effectively save the energy consumption of enzymatic hydrolysis reaction. Add 0.3% compound enzyme composed of pectinase, amylase and protease to the mixture according to the weight ratio of 1:3:0.5, and react for 1.5 hours. The hydrolysis reaction can decompose pectin, protein, starch and other organic components in the colored wastewater, so that the clarity and transparency of the product can be improved;

[0051] (2) Centrifugation: place the mixture in a centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com