Wire drawing method of high-stress active polarization-maintaining fiber prefabricated rod

An optical fiber preform and polarization-maintaining optical fiber technology, which is applied in the field of optical fiber manufacturing, can solve the problems of increased optical fiber transmission loss, poor laser beam quality, and easy deformation of the fiber core, so as to reduce the deformation amount, improve the utilization length, and ensure the geometric accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

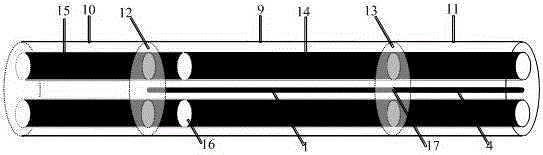

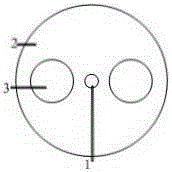

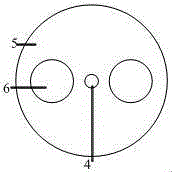

[0018] In order to facilitate the understanding of those skilled in the same industry, the features of the present invention and other related features will be further described below through embodiments in conjunction with the accompanying drawings.

[0019] Such as Figures 1 to 4 As shown, a high-stress active polarization-maintaining optical fiber preform drawing method, the steps are as follows:

[0020] In the first step, the rare earth ion-doped active optical fiber preform 9 is deposited by CVD process. After the deposition is completed, the active optical fiber preform 9 is removed for annealing. The active optical fiber preform 9 includes the active optical fiber preform cladding 2, Active optical fiber preform core 1;

[0021] In the second step, prepare a quartz rod 10 and an optical fiber preform 11 having the same outer diameter as the active optical fiber preform 9 respectively, the quartz rod 10 includes an upper quartz rod cladding 7, and the optical fiber pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com