Frosting processing device

A processing device and frosting technology, applied in the field of glass deep processing, can solve the problems of operator injury, non-recyclable use, serious environmental impact, etc., and achieve the effects of reducing direct contact, improving production efficiency, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

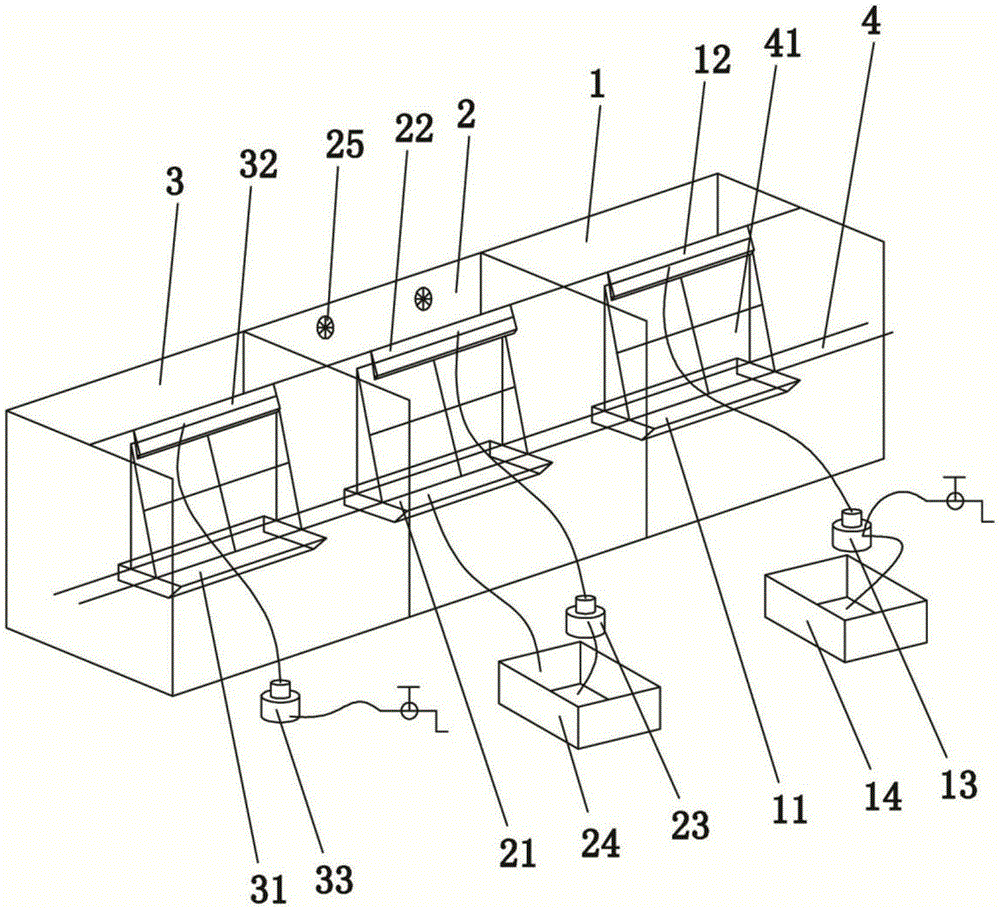

[0017] Such as figure 1 As shown, a frosting processing device according to the present invention includes a cleaning chamber 1, a frosting chamber 2, a recovery chamber 3 and a transfer track 4, and the cleaning chamber 1, the frosting chamber 2 and the recovery chamber 3 are arranged side by side in sequence And separated from each other by plastic curtains, the cleaning room 1 is provided with a cleaning pool 11, and a cleaning mechanism that cooperates with it is provided above the cleaning pool 11; a frosting pool 21 is provided in the frosting room 2, and a The frosting mechanism that cooperates with it; the recovery tank 31 is provided in the recovery room 3, and the dripping mechanism that cooperates with it is provided above the recovery tank 31; the transfer track 4 is set in the cleaning room 1, the frosting room 2, the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com