Rubber composition for high-speed energy-saving tire tread

A technology of rubber composition and tire tread, which is applied in special tires, tire parts, rolling resistance optimization, etc., can solve the problem of reducing rolling resistance and put it in a dominant position, so as to reduce rolling resistance and dynamic heat generation, and eat materials Improved performance and shortened kneading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

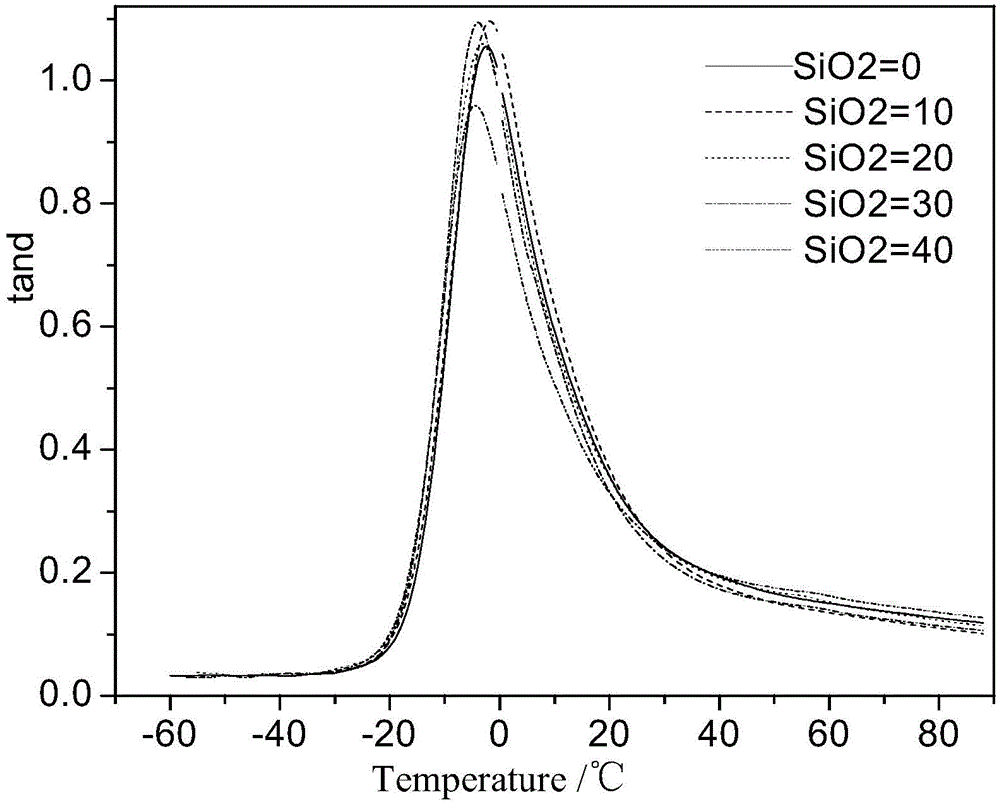

[0037] The basic formula is the same as that of Comparative Example 1, the difference is that the mass ratio of N220 / N330 / silica is 10 / 30 / 10 respectively, and its physical and mechanical properties and aging properties are shown in Table 2-3, the dynamic viscoelastic data of HVPBR vulcanizate See Table 4, the DMA curve of vulcanizate see figure 1 .

Embodiment 2

[0039] The basic formula is the same as that of Comparative Example 1, the difference is that the mass ratio of N220 / N330 / silica is 10 / 25 / 15 respectively, and its physical and mechanical properties and aging properties are shown in Table 2-3, the dynamic viscoelasticity data of HVPBR vulcanizate See Table 4, the DMA curve of vulcanizate see figure 1 .

Embodiment 3

[0041] The basic formula is the same as that of Comparative Example 1, the difference is that the mass ratio of N220 / N330 / silica is 10 / 20 / 20 respectively, and its physical and mechanical properties and aging properties are shown in Table 2-3, the dynamic viscoelastic data of HVPBR vulcanizate See Table 4, the DMA curve of vulcanizate see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com