A washing machine deceleration clutch and washing machine

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve problems such as waste of bottom space, achieve the effects of increasing washing capacity, reducing axial space occupation, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

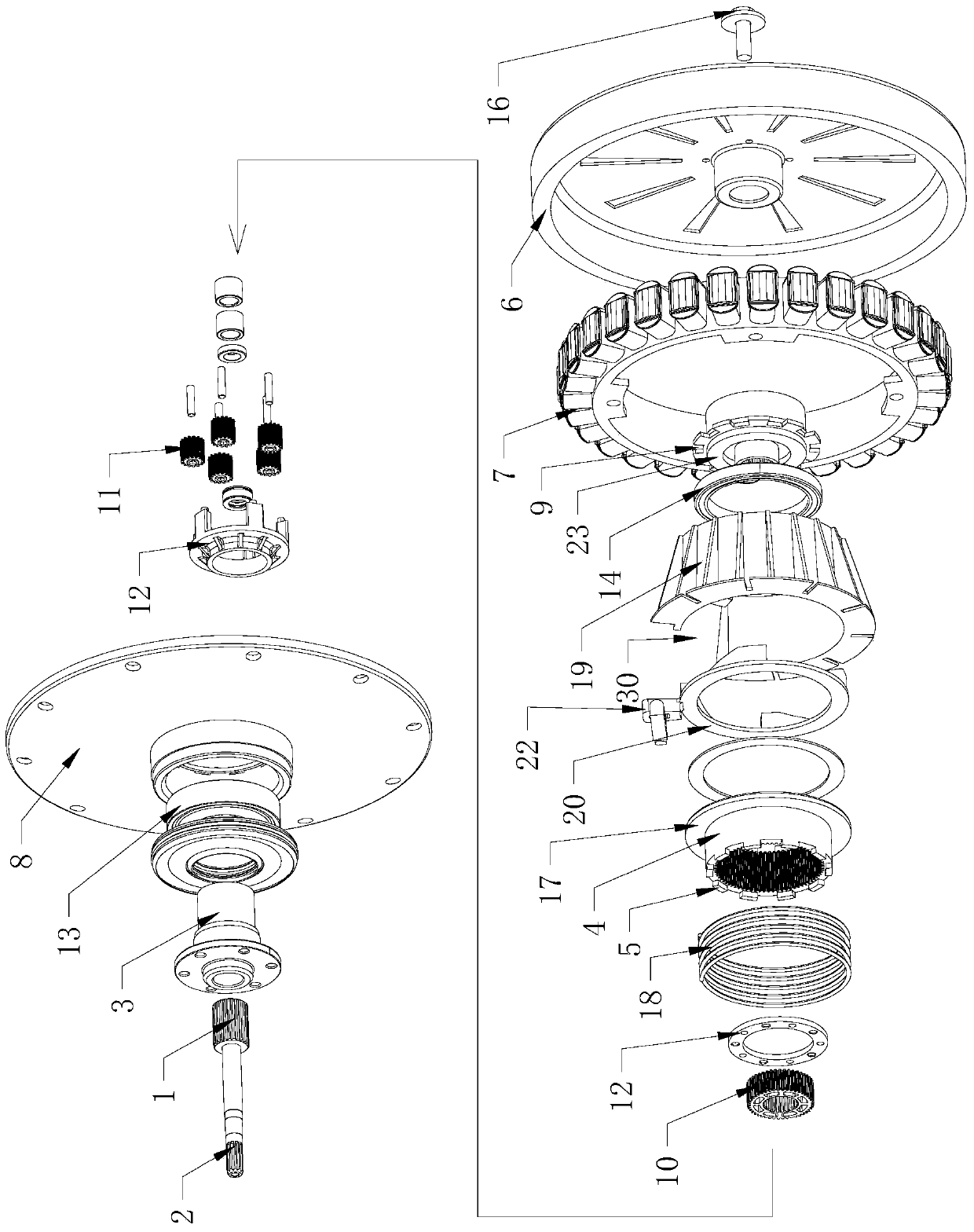

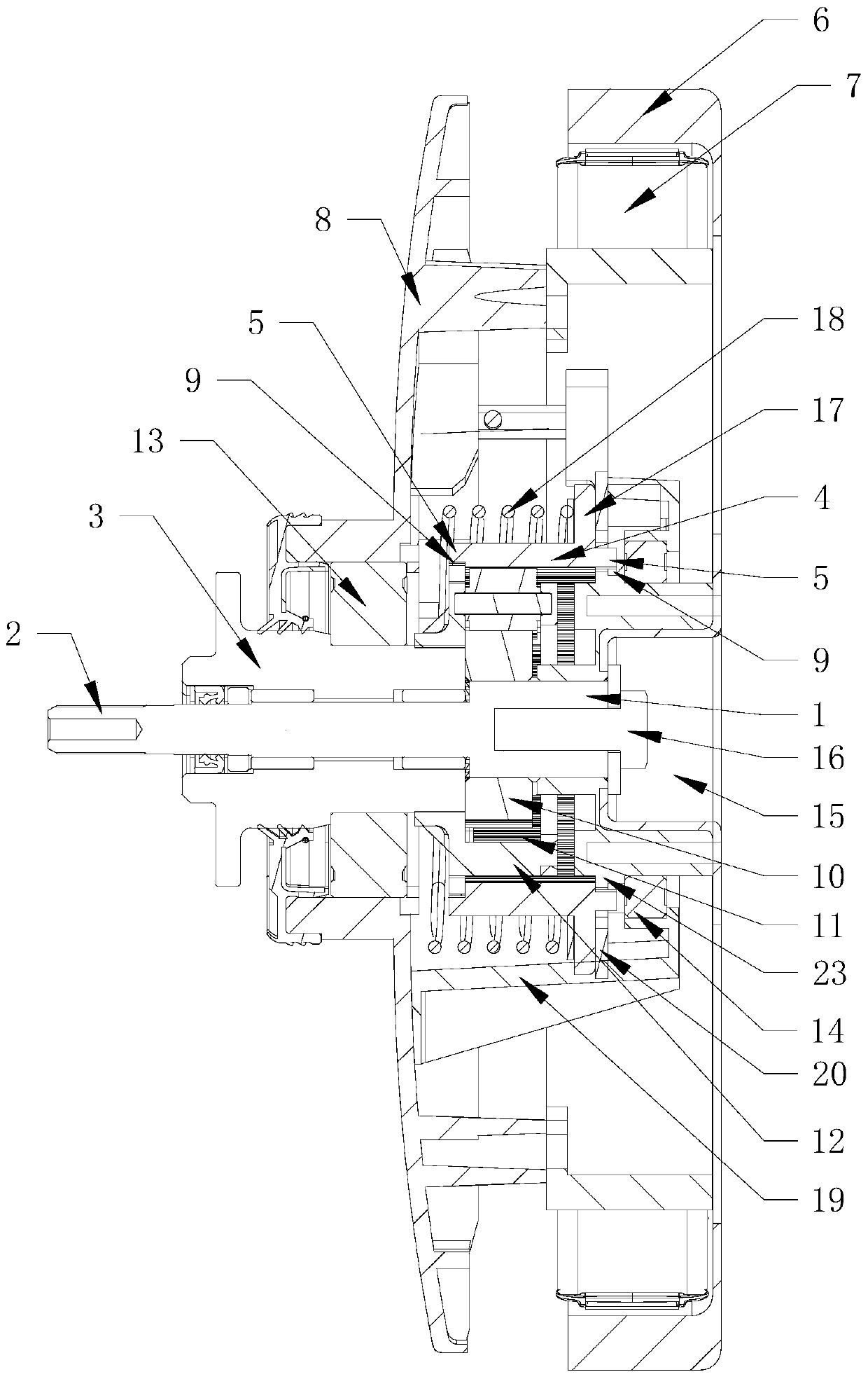

[0038] Such as figure 1 , figure 2 As shown, a washing machine deceleration clutch according to the present invention includes: an input shaft 1, a deceleration device, a clutch device, an output shaft 2 and an output shaft sleeve 3, and the clutch device is arranged on the peripheral periphery of the deceleration device, and on the input shaft The projections on the straight line are at least partially overlapped, and the clutch device at least includes a clutch sleeve that can move axially, and the clutch sleeve is the ring gear 4 of the reduction gear, and the structure of the ring gear 4 that moves axially and in different states connected to control different output states of the output shaft 2 and the output sleeve 3, and the ring gear 4 meshes with at least part of the gears in the reduction gear.

[0039] If the above-mentioned washing machine is a vertical bucket pulsator washing machine, the output shaft 2 is connected to the pulsator, and the output bushing 3 is c...

Embodiment 2

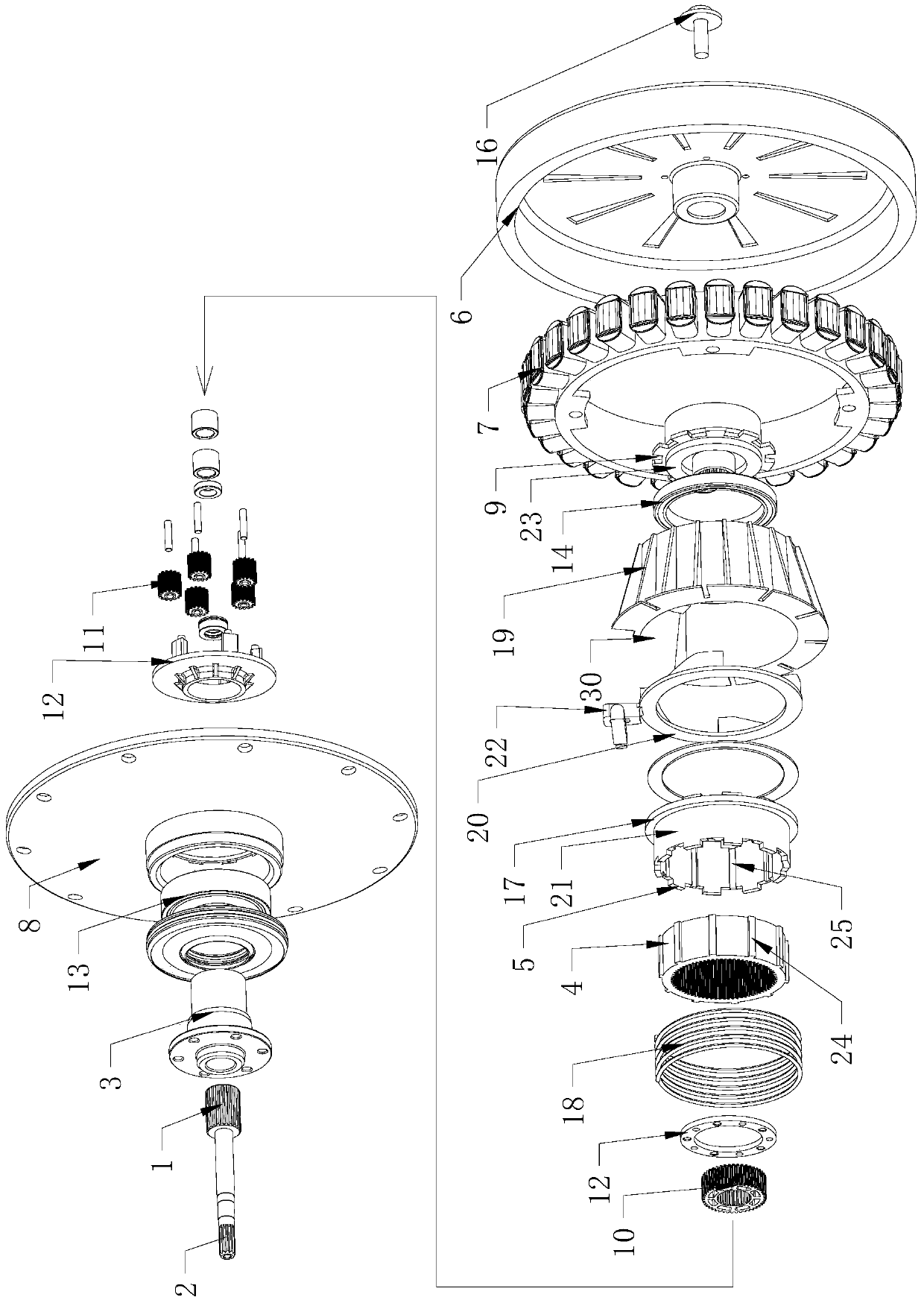

[0072] Such as image 3 , Figure 4 As shown, a washing machine deceleration clutch according to the present invention includes: an input shaft 1, a deceleration device, a clutch device, an output shaft 2 and an output shaft sleeve 3, and the clutch device is arranged on the circumferential periphery of the deceleration device, and the clutch The device at least includes a clutch sleeve 21 that can move axially, and the clutch sleeve 21 is arranged outside the ring gear 4 of the deceleration device, and is connected with the ring gear 4 in an axially relative sliding and circumferentially non-rotatable manner. The shaft sleeve 21 moves axially so that the ring gear 4 is connected to structures in different states through the clutch sleeve 21 to control the different output states of the output shaft 2 and the output sleeve 3. The ring gear 4 is connected to at least part of the reduction gear. gears meshing.

[0073] If the above-mentioned washing machine is a vertical bucke...

Embodiment 3

[0106] A washing machine having the deceleration clutch described in the first or second embodiment above, the washing machine is a pulsator washing machine or a drum washing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com