A Fully Symmetrical Decoupling Direct Output Frequency Vibration Gyroscope

A technology of output frequency and vibrating gyroscope, which is applied in the direction of speed measurement, gyroscope/steering sensing equipment, measuring device, etc. due to the gyro effect, which can solve the problems of serious mechanical coupling, lower production cost, and lower performance of gyroscope, and achieve anti-interference ability. Enhancement, increased sensitivity and measurement accuracy, reduced overall size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

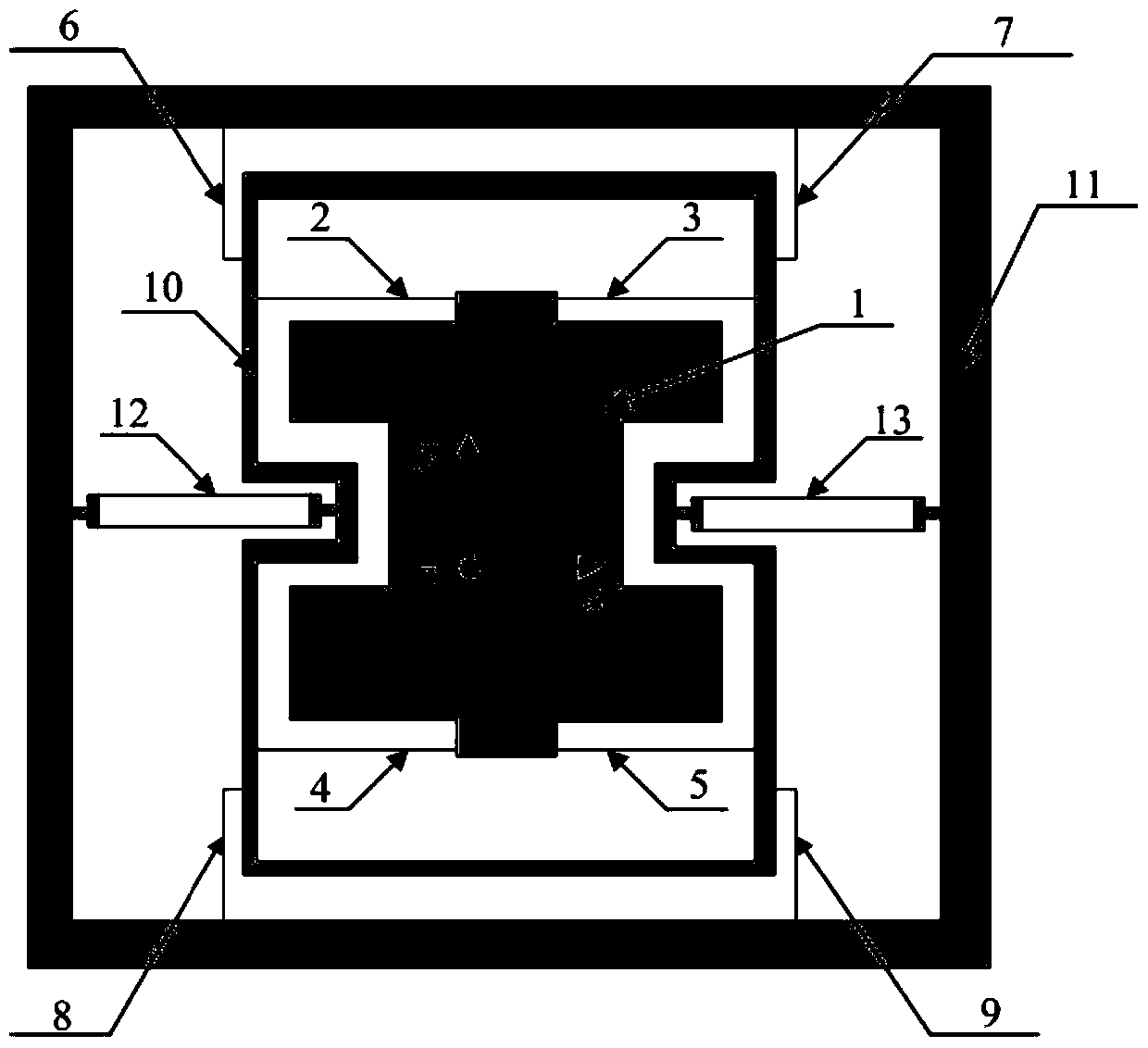

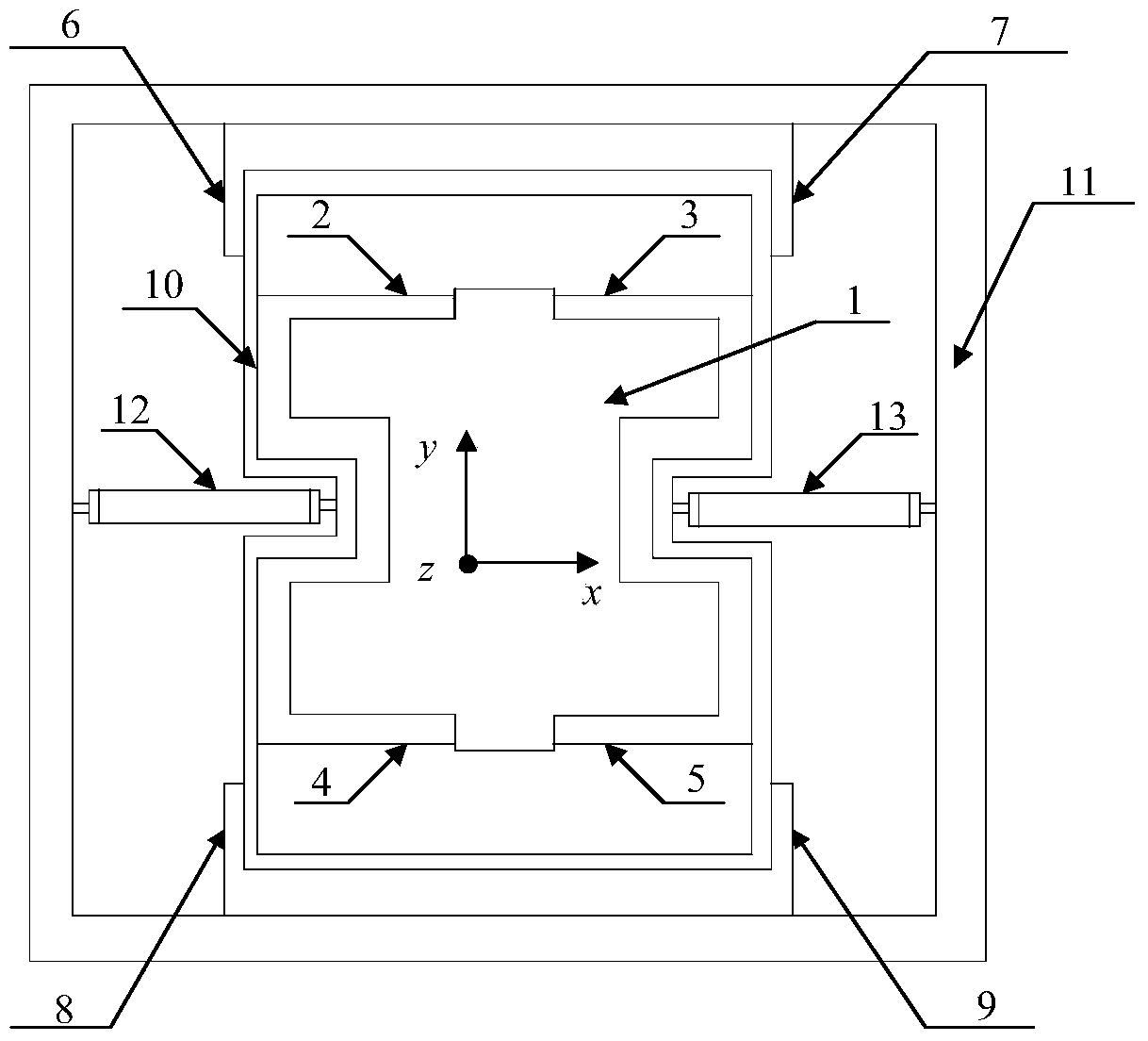

[0020] The design features of the gyroscope of the present invention are: (1) the direct output frequency is adopted, which greatly reduces signal loss and realizes weak Coriolis effect FM modulation. (2) The fully symmetrical structure makes it easy to match the resonant frequencies of the driving and detection modes, and also realizes the damping matching of the two modes, which can reduce the drift caused by process errors and environmental temperature changes. (3) The double-frame decoupling structure can reduce the quadrature error and improve the signal-to-noise ratio of the gyroscope. (4) Using a differential resonant structure can increase sensitivity and suppress most types of common-mode interference. (5) Planar scheme design, easy to adapt to wire-cut processing or MEMS-related processes, and easy to miniaturize.

[0021] A detailed description will be given below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the vibrating gyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com