Telephoto type super-large image plane high definition lens and installation method thereof

A telephoto and lens technology, applied in optical components, optics, instruments, etc., can solve the problems of increased design difficulty, difficult ratio, difficult application, etc., to achieve enhanced optical information collection capabilities, overcome serious front-to-back separation, and high-resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

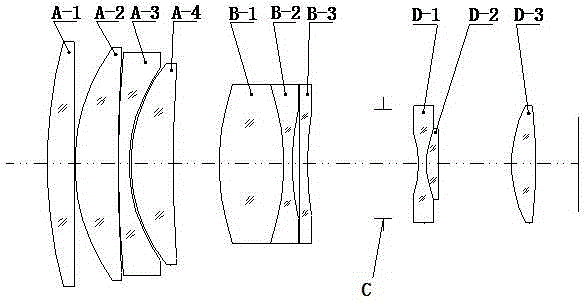

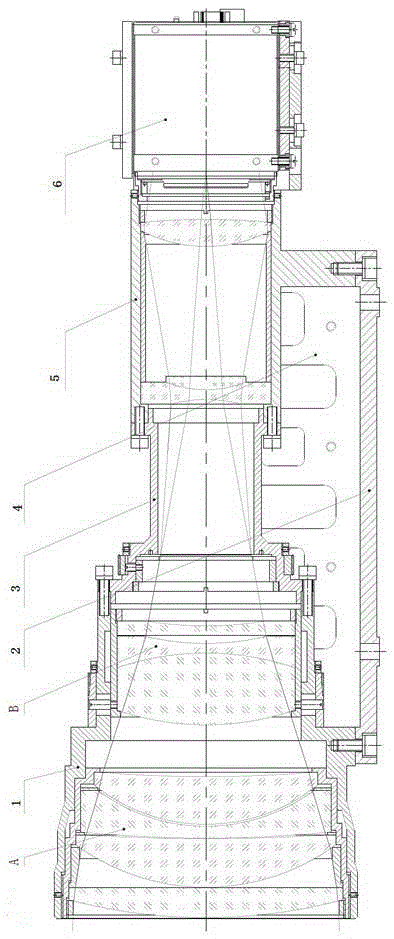

[0022] Such as Figure 1~2 As shown, a telephoto ultra-large image surface high-definition lens is characterized in that: the mechanical structure of the lens includes a main lens barrel, a rear group lens barrel, and a CCD assembly that are sequentially installed and connected to the base plate from left to right. The main lens barrel and the rear group of lens barrels are connected through a diaphragm seat. The optical system of the lens includes a front fixed group A with a positive refractive power and a focal power of Negative focusing group B, iris C, and rear fixed group D with positive refractive power, the front fixed group A and focusing group B are arranged in the main lens barrel, and the rear fixed group D is arranged in Inside the rear lens barrel.

[0023] In this embodiment, the front fixed group A includes a plano-convex lens A-1, a positive crescent lens A-2, a negative crescent lens A-3, and a positive crescent lens A-4 arranged in sequence. B includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com