A tandem white organic light emitting device

An organic light-emitting device, white technology, applied in the direction of organic semiconductor devices, electric solid devices, semiconductor devices, etc., can solve the problems of high voltage and difficult preparation, and achieve the effects of improving efficiency, reducing equipment costs, and reducing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

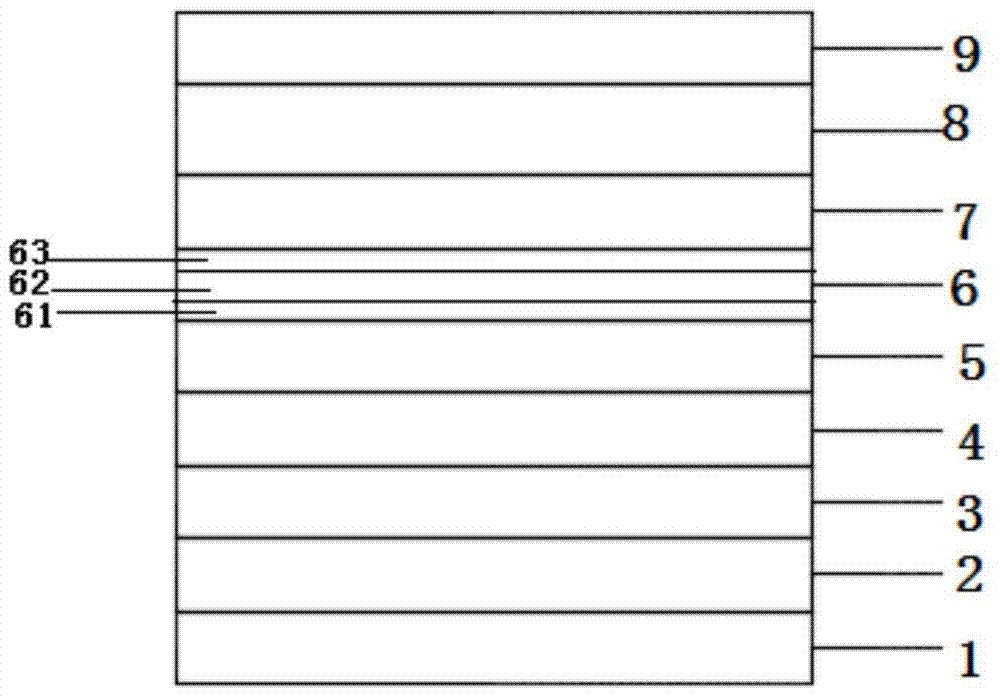

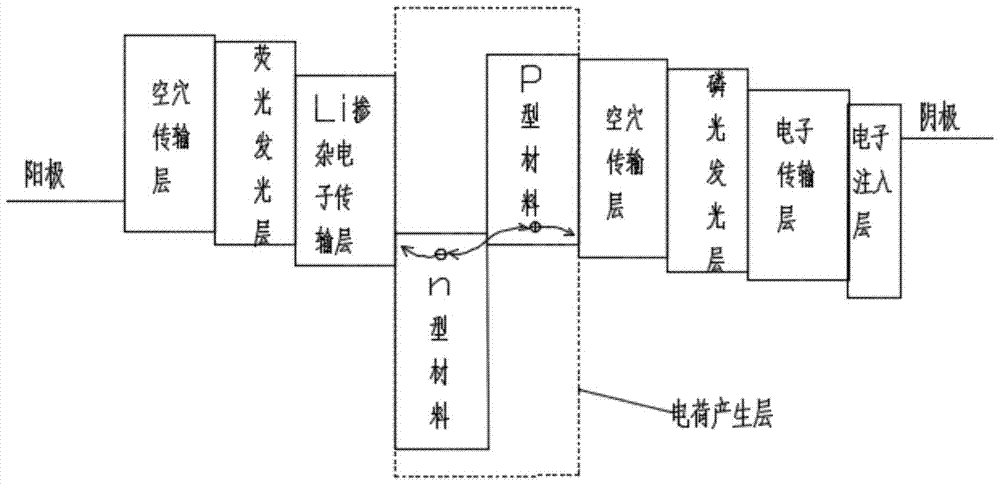

[0031] Such as figure 1 As shown, a tandem white organic light-emitting device of the present invention includes a substrate, and a first electrode layer 1, several blue-light fluorescent light-emitting units, several charge generation layers, several phosphorescent light-emitting units with a light-emitting wavelength greater than 500 nm, and a first electrode layer 1 are stacked. Two electrode layers 9; figure 1 The blue fluorescent light-emitting unit and the phosphorescent light-emitting unit of the serial white organic light-emitting device shown are one layer respectively.

[0032] An n-type charge generation layer 5 made of an n-type material is arranged between the adjacent blue fluorescent light-emitting units and phosphorescent light-emitting units; Phosphorescent emitting layer.

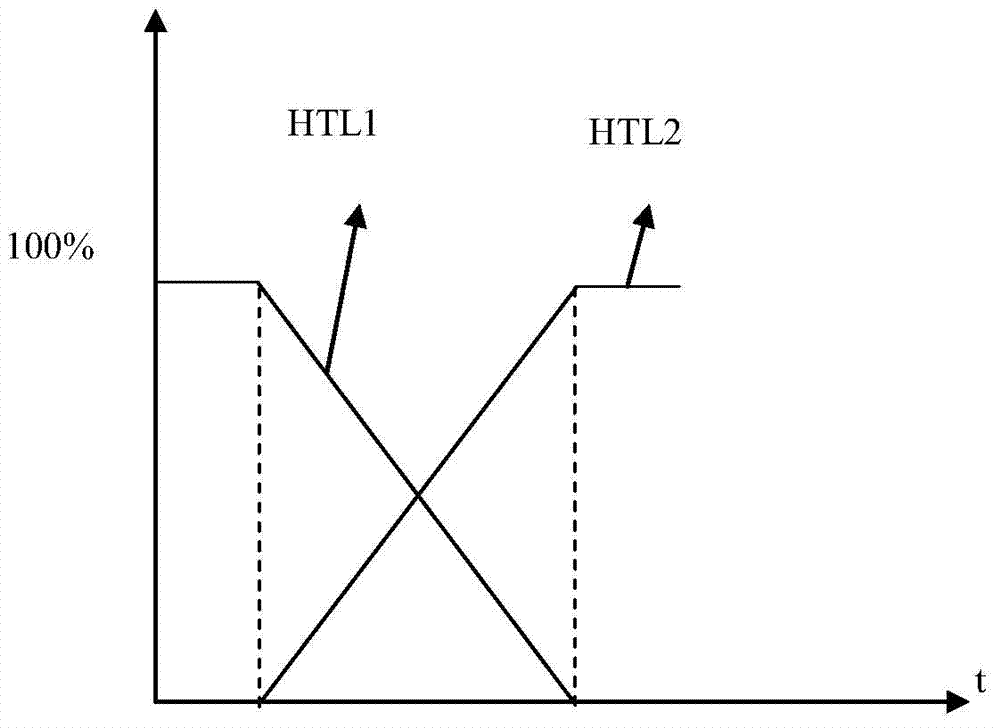

[0033] The phosphorescent light-emitting unit includes a first hole transport layer 6, a phosphorescent light-emitting layer 7 and a first electron transport layer 8; the first hole tran...

Embodiment 2

[0066] Such as Figure 4 As shown, a tandem white organic light-emitting device of the present invention includes a substrate, and a first electrode layer 1, a phosphorescent light-emitting unit, an n-type charge generation layer 5, a blue fluorescent light-emitting unit, an n-type charge generation layer 5, a phosphorescent The light emitting unit and the second electrode layer 9; other structures are the same as those in Embodiment 1. Specifically, a first electrode layer 1, a hole injection layer 10, a first hole material layer 61, a transition layer 62, a second hole material layer 63, a phosphorescent layer 7, and a first electron transport layer are stacked on the substrate. 8. The n-type charge generation layer 5, the second hole transport layer 2, the blue fluorescent light-emitting layer 3, the second electron transport layer 4, the n-type charge generation layer 5, the first hole material layer 61, the transition layer 62, the second Two hole material layers 63 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com