Method of manufacturing positive electrode for solid-state battery, method of manufacturing solid-state battery, and positive electrode slurry

A positive electrode slurry and solid battery technology, which is applied in electrode manufacturing, electrolyte storage battery manufacturing, battery electrodes, etc., can solve the problems of battery output drop, resistance rise, peeling, etc., and achieve the effect of suppressing battery output drop and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Hereinafter, the present invention will be described in detail based on examples, but the present invention is not limited to the following specific embodiments.

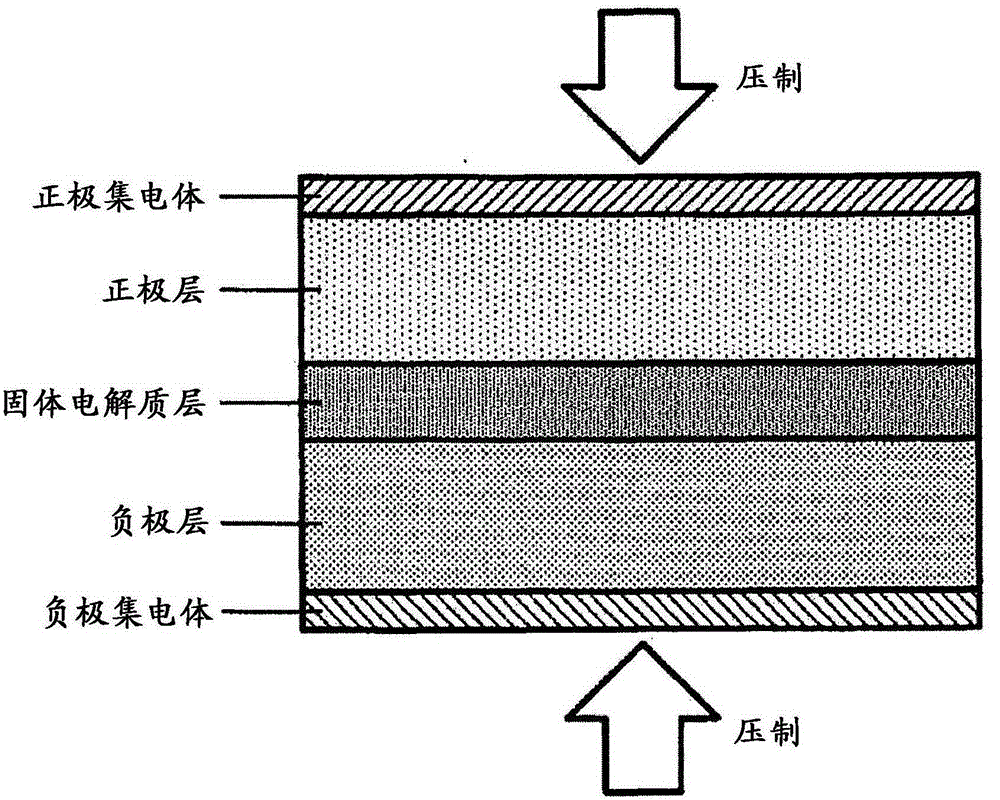

[0071] 1. Issues with conventional adhesives

[0072] A three-component system copolymer containing VDF monomer units, TFE monomer units and HFP monomer units is used as a binder to form a positive electrode slurry, and the slurry is coated and then dried quickly to form a positive electrode. When a battery is produced from this positive electrode, there is a problem that the output of the battery decreases compared with the case where the positive electrode is produced by natural drying. After intensive research, it was found that the reason was that the binder segregated on the surface of the positive electrode during rapid drying, and the resistance increased. On the other hand, conventional combinations of a binder and a solvent have problems in that the adhesion between the positive electrode layer and ...

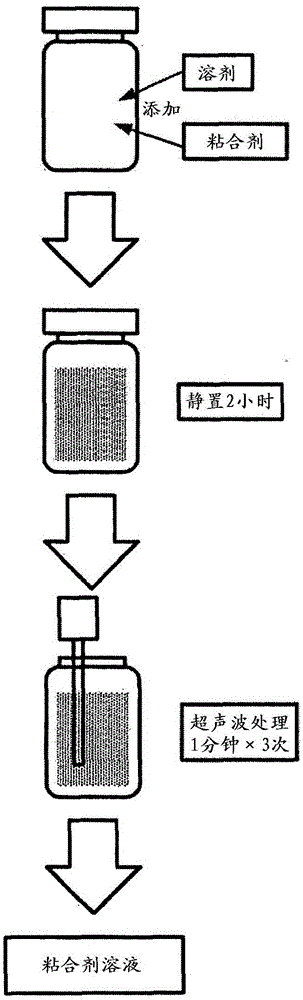

preparation example 1

[0076] (Preparation Example 1) Powder of polyvinylidene fluoride (PVDF, VDF 100%) was added to butyl methacrylate (manufactured by Kishida Chemical Co., Ltd.), and stirred overnight to prepare a binder solution (1). Here, the whole of the binder solution (1) was regarded as 100% by mass, and it was operated so as to contain 20% by mass of the binder. In addition, since PVDF cannot be dissolved and dispersed in butyl butyrate, butyl methacrylate was used instead of butyl butyrate as a solvent for the binder solution.

preparation example 2

[0077] (Preparation Example 2) Prepare a binder powder of a three-component system copolymerized at a ratio of VDF:TFE:HFP=55 mol%:25 mol%:20 mol%, and add it to butyl butyrate (manufactured by Kishida Chemical Co., Ltd. ), stirred overnight to dissolve the binder, and prepare the binder solution (2). Here, the whole of the binder solution (2) was regarded as 100% by mass, and it was operated so as to contain 5% by mass of the binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com