Hinged type wire connector

A wire connector and connector technology, applied in the direction of adjusting/maintaining mechanical tension, cable suspension device, etc., can solve the problem of not considering the tension bearing capacity of the wiring clip, etc., and achieve simple structure, good tension bearing capacity, and bearing tension capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

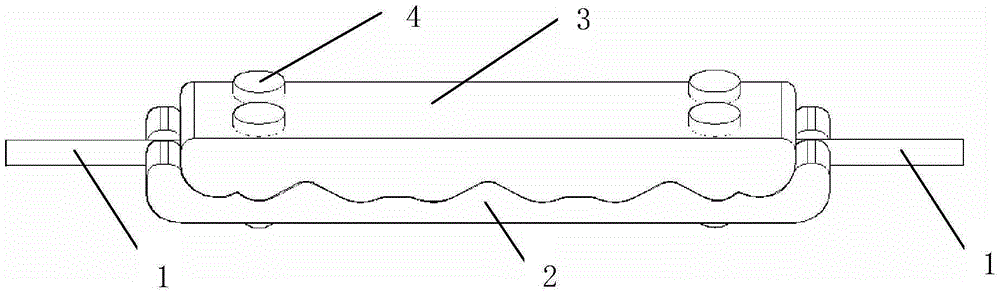

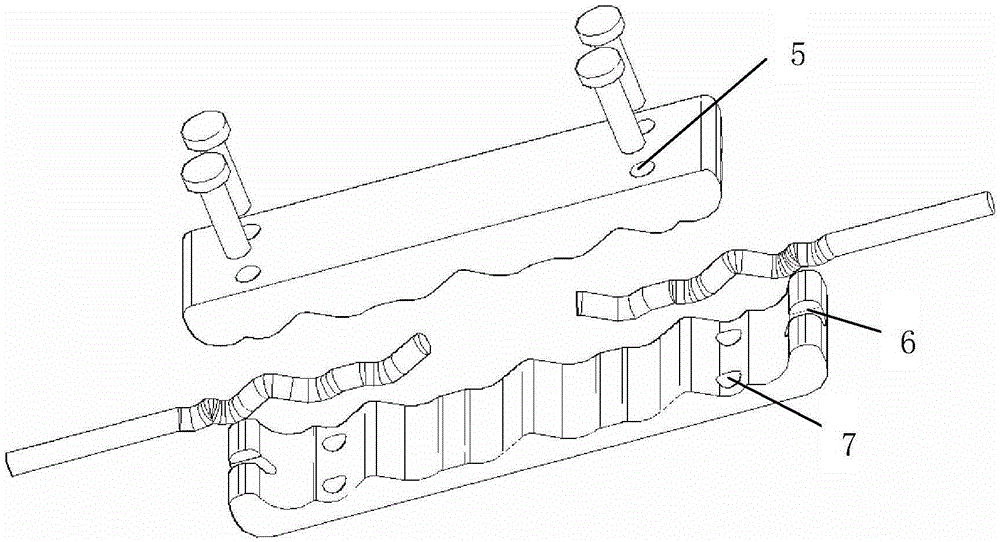

[0038] A hinge-type wire connector, including a connector body 2, a pressing block 3, and a locking device for detachably connecting the connector body 2 and the pressing block 3, and one surface of the connector body 2 is provided with concave and convex pressure lines Correspondingly, one surface of the pressing block 3 is provided with a matching concave-convex crimping structure, the shape of the concave-convex crimping structure is arbitrary, and it can be a wave-shaped undulating structure set on the surface of the connector body and the pressing block , or other structures that make the above-mentioned surface not a horizontal surface in the longitudinal direction; and at least one of the connector body 2 and the pressing block 3 is provided with a limiting structure for preventing the wire from sliding laterally; preferably a wire hole or a wire groove 6, When in use, the wire 1 is set between the concave-convex crimping structure of the connector body 2 and the concavo...

Embodiment 2

[0048] On the basis of the technical solution of the wire binding clip described in embodiment 1, the following improvements have been further made:

[0049] Such as Figure 6 , 7 As shown in and 10, a pair of wire holes or wire slots 6 are provided on the connector body 2 or the pressing block 3; the pair of wire holes or wire slots 6 can accommodate more than two wires; the two or more The wires are respectively inserted from the wire hole or the wire groove 6 at one end of the connector body 2 or the pressing block 3, and are arranged in more than two corresponding wire insertion grooves 8; the locking device includes more than two locking screws 4 , its position is set on both sides of the wire slot 8;

Embodiment 3

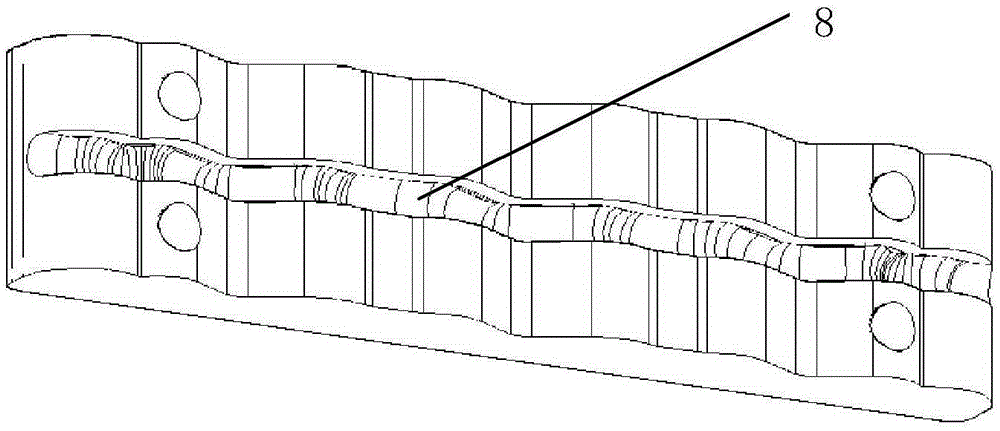

[0051] On the basis of the technical solution of the wire binding clip described in embodiment 1, the following improvements have been further made:

[0052] Such as Figure 8 , 9 As shown in and 11, two or more pairs of wire holes or wire grooves 6 are arranged at intervals on the connector body 2 or the pressing block 3; The wire holes or wire grooves 6 are inserted and set in more than two corresponding wire insertion grooves 8; the locking device includes more than two locking screws 4, and their positions are set on both sides of the wire insertion groove or two wire insertion grooves. between slots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com