double material feeder

A feeder and feeder technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of limited placement space of automatic feeders, inability to complete chip placement, increase production costs, etc., to improve user experience, Effects of increasing supply types and improving placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

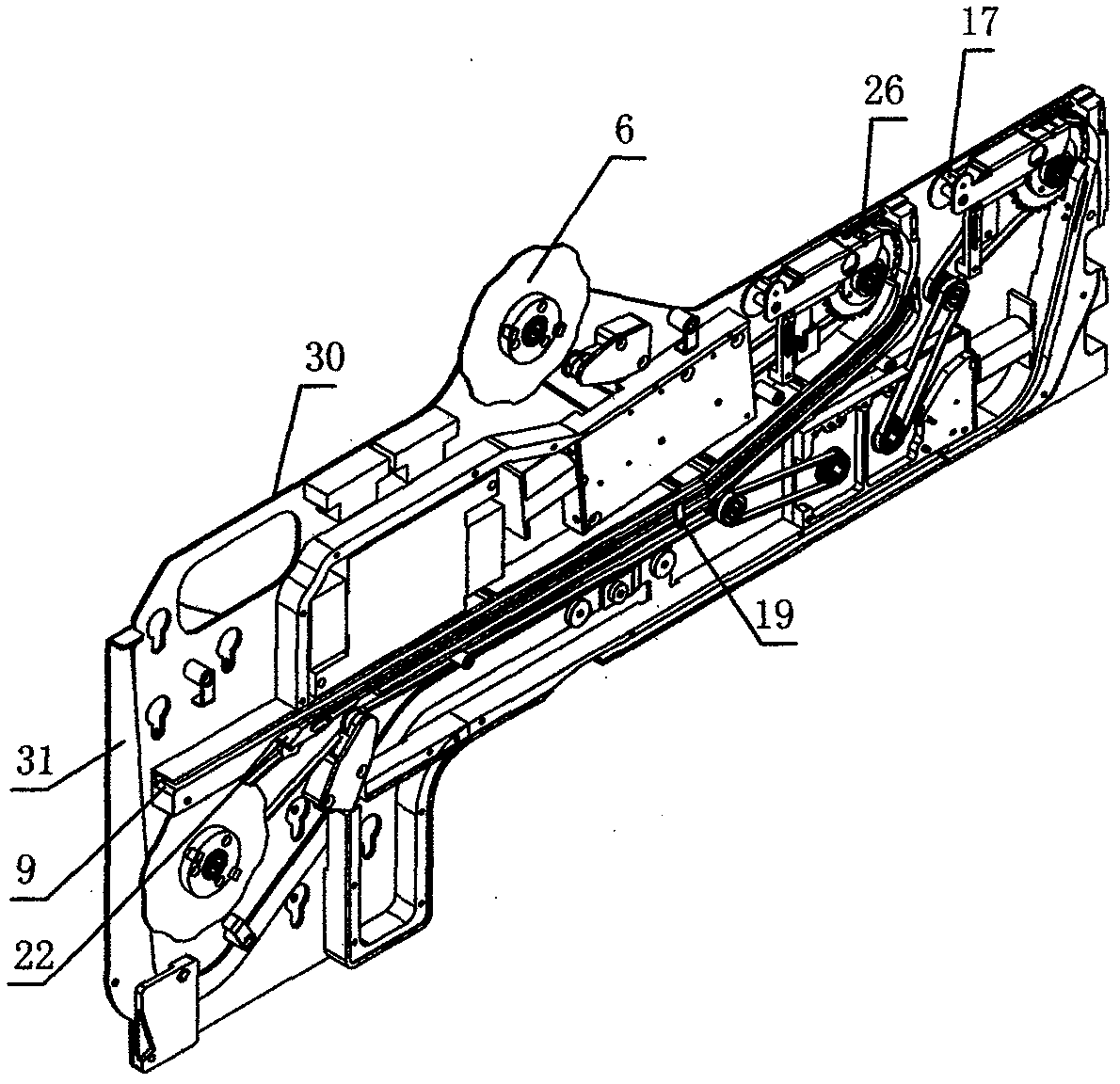

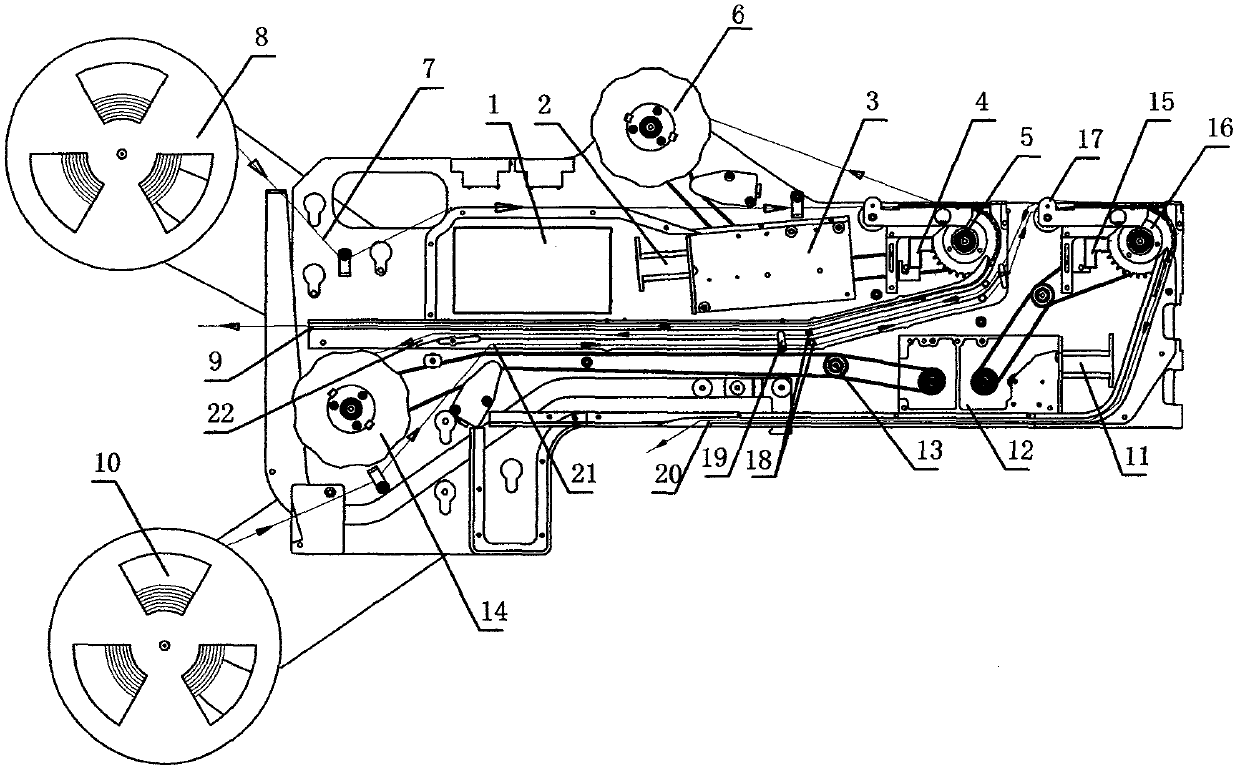

[0022] Attached below figure 1 , figure 2 The present invention is further described:

[0023] The double-material feeder of the present invention includes a main board 30, a main circuit board 1, a front side sealing plate, a rear side sealing plate, a locking mechanism 31, a first feeding system and a second feeding system. The main board 30 is the support board of the entire double material feeder, the main circuit board 1, the locking mechanism 31, the first feeding system and the second feeding system are respectively connected on the main board 30, at the same time, the front side sealing board and the rear side sealing board The board shields the main circuit board 1, the first feeding system and the second feeding system from both sides, so as to ensure the safety of the main circuit board 1, the first feeding system and the second feeding system.

[0024] The first feeding system includes a first servo motor 2, a first reducer 3, a first transmission system, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com