Lithium-containing molding material mixture based on an inorganic binder for producing molds and cores for metal casting

A technology of inorganic adhesives and molding materials, applied in the direction of manufacturing tools, metal processing equipment, cores, etc., can solve the problem of no mold strength specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0139] 1. Preparation of Water Glass Adhesive from Lithium Hydroxide Solution

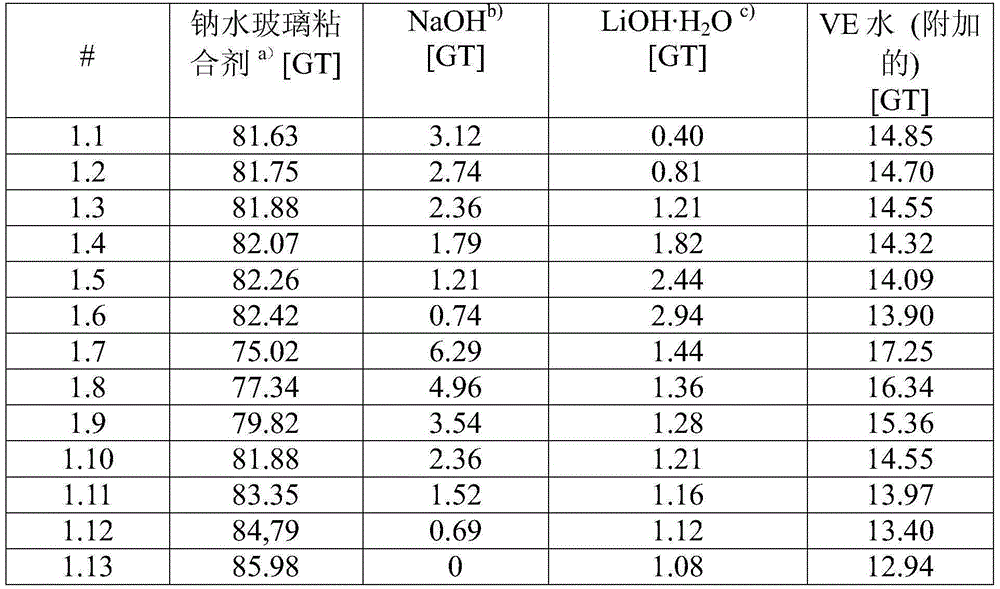

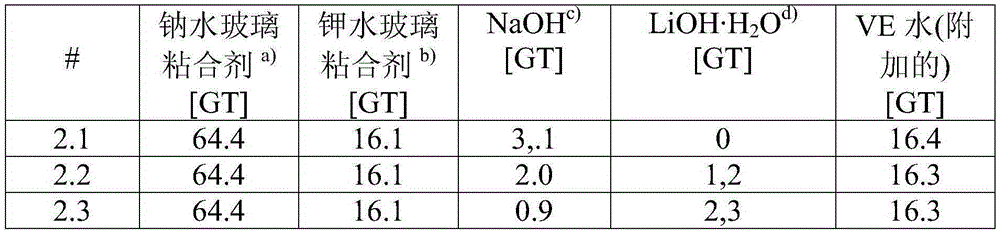

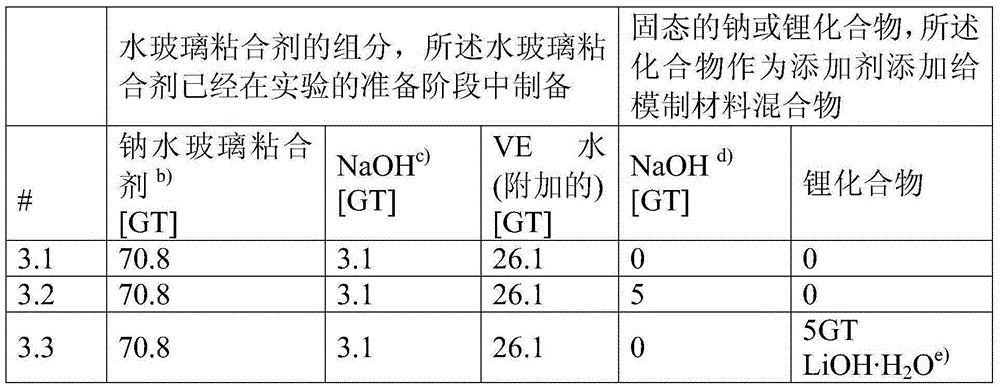

[0140] Tables 1, 2, 3 and 4 provide an overview of the components of the various inventive and non-inventive waterglass binders investigated in the current field of research. The preparation of the water glass binder is carried out by mixing the chemicals set forth in Table 1 or 2 such that a homogeneous solution exists. The application of the solution was carried out one day after its preparation in order to ensure its homogeneity. Alkali oxides and [SiO 2 ] concentration and its molar ratio and [Li 2 o aktiv ] / [M 2 The mass ratios of substances for O] are summarized in Tables 4 and 5. Table 3 gives an overview of the molding material mixture in which the lithium compound was added via the additive component. Here, the addition of solid lithium compounds together with amorphous SiO 2 together (see 2.1).

[0141] 2. Research on Storage Stability

[0142] 2.1 Preparation of molding mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com