Medium-caliber juicer structure

A juicer and caliber technology, which is applied to the structure field of medium-caliber juicers, can solve the problems of insufficient juice yield, insufficient cutting force, low juicing efficiency, etc., and achieves high extraction rate, stable crushing process, and not easy to accumulate heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

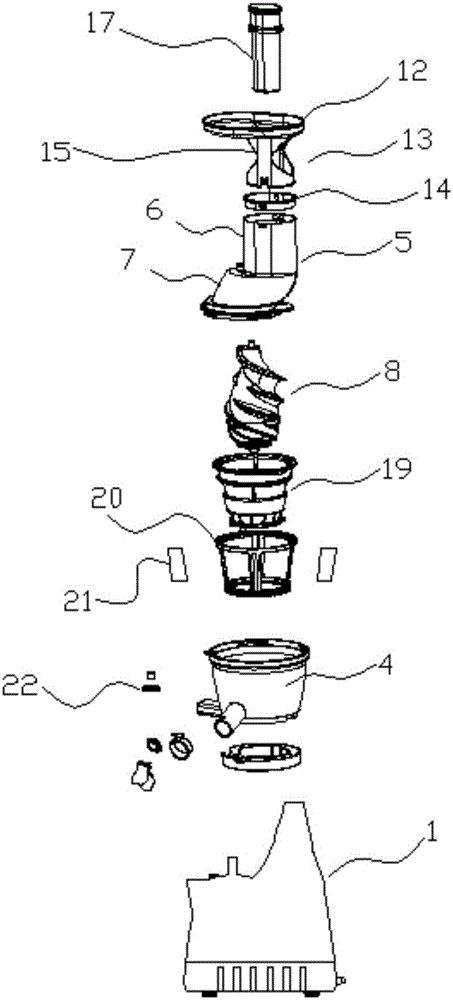

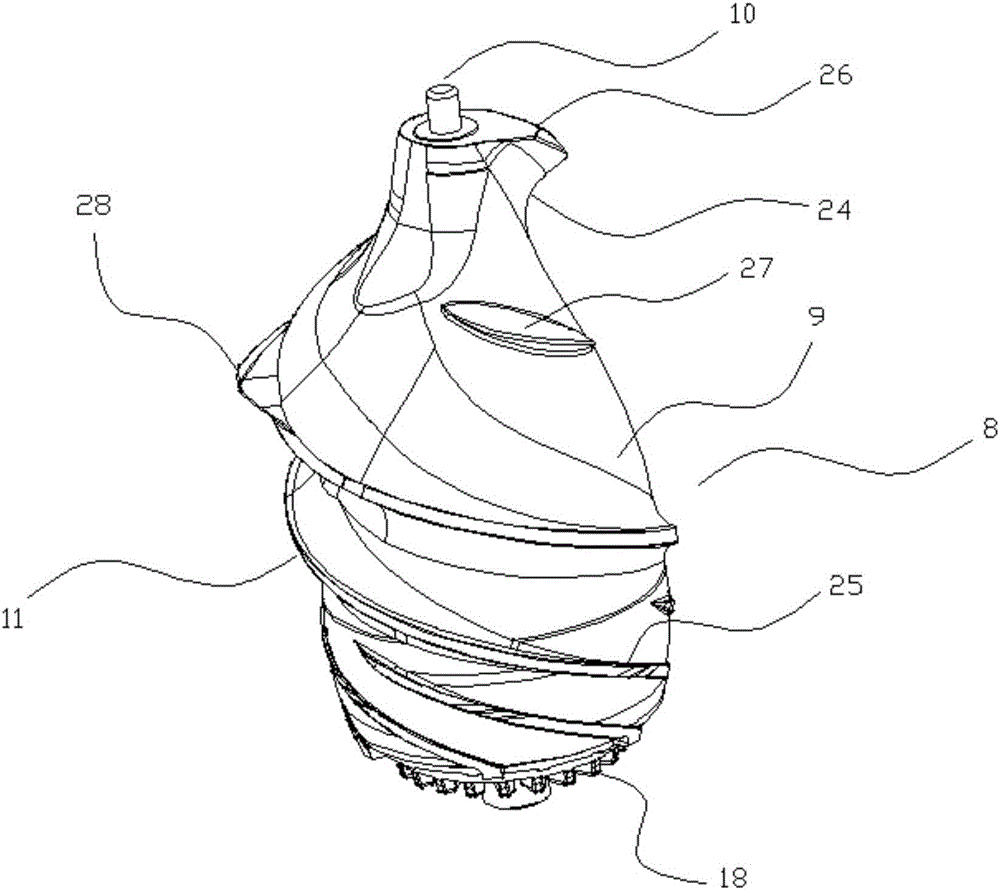

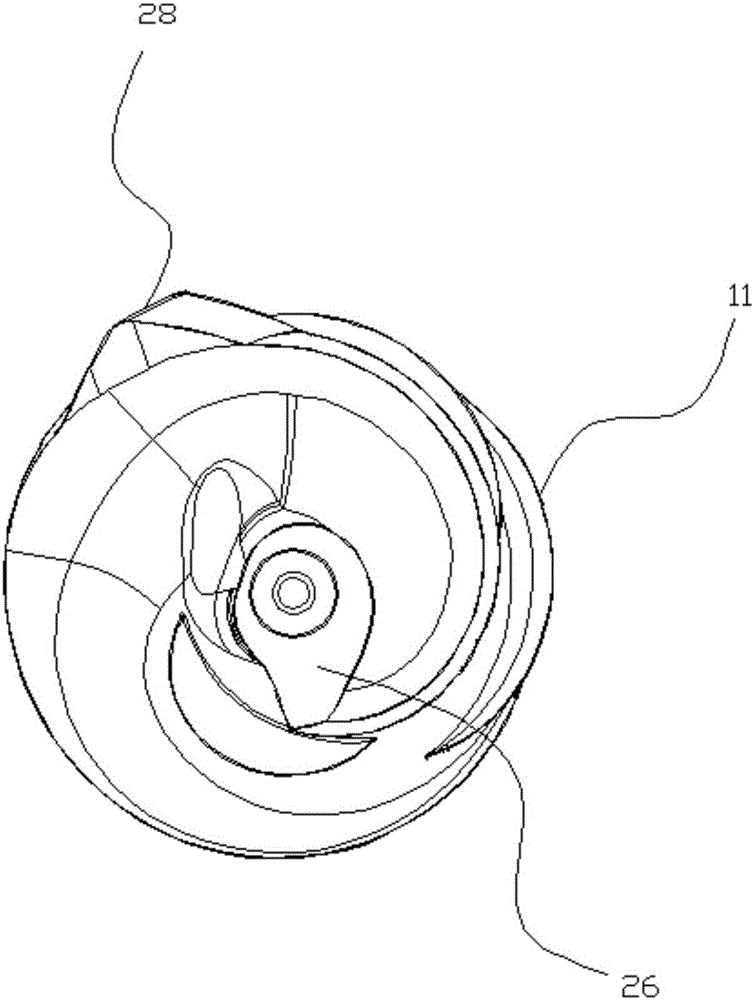

[0032] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 In the shown embodiment, a structure of a medium-caliber juice extractor includes a lower machine base 1 and an upper body, the lower machine base is provided with a motor 2, and the upper body includes a feeding part 3, The juice collecting tray 4, the main feeding barrel 5 above the juice collecting tray, the main feeding barrel includes the lower feeding barrel 6, the feeding barrel 7, the space in the feeding barrel and the space in the juice collecting tray together constitute a juice extraction cavity, so A juicing net assembly with an open upper end is arranged in the juice collection tray, and a juice squeezing screw body 8 is arranged in the juice squeezing cavity, and the juice squeezing screw body includes a juice squeezing screw body 9 and an output shaft of the motor. Connected central shaft 10, the juice extracting screw is sleev...

Embodiment 2

[0039] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown in , the juice extracting screw body is provided with several horizontal fine material grooves, and the concentrated material groove includes an outer groove section 39 and an inner groove section 40, and the outer end of the outer groove section opens at the juice squeezing screw body On the side wall, the inner tank section is provided with a recovery spring 41 connected to the juice extraction screw, and the outer tank section is provided with a fine material part connected with the recovery spring, and the fine material part includes A slide block 42 that can slide laterally in the outer groove section, and a fine material rod 43 connected with the slide block, the outer end of the fine material rod is provided with an elastic sealing head 44 . When the juice s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com