Three axis mechanical arm automatic grabbing device

A technology of grabbing device and robotic arm, which is applied in the field of three-axis robotic arm automatic grabbing device, can solve problems such as low production efficiency, high labor intensity, and laborious operators, and achieve the effects of improved efficiency, simple structure, and simple action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

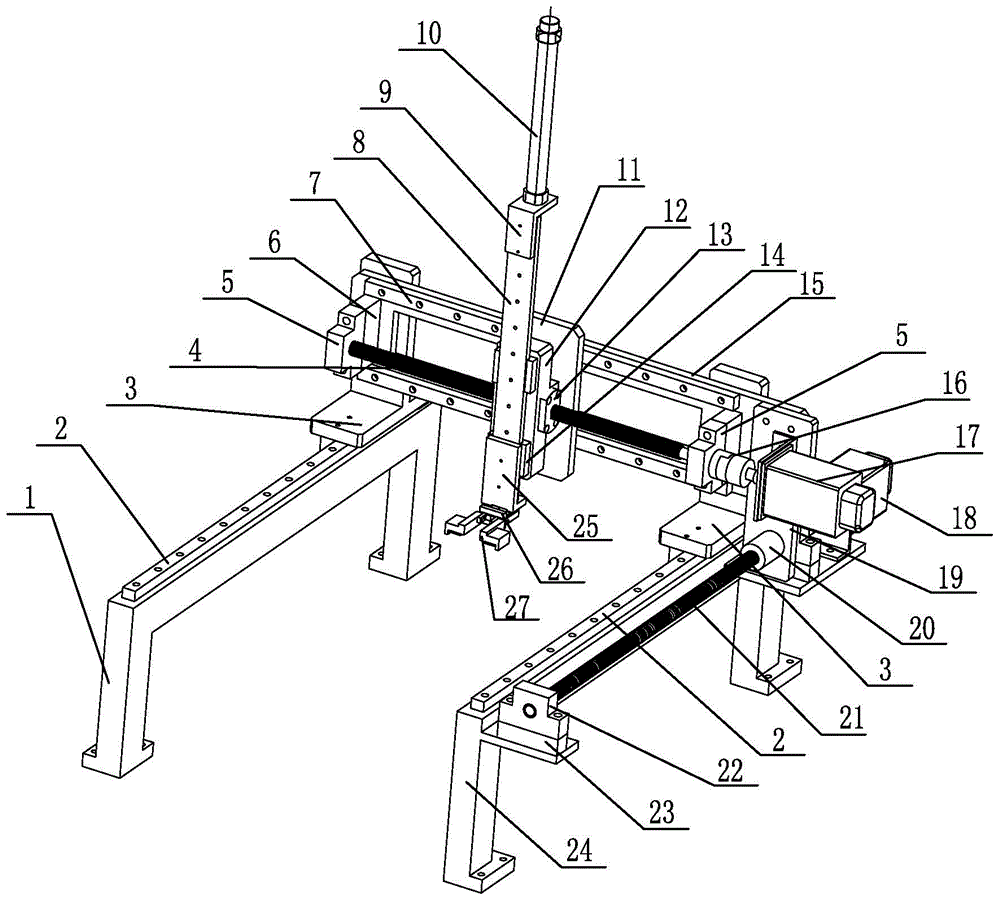

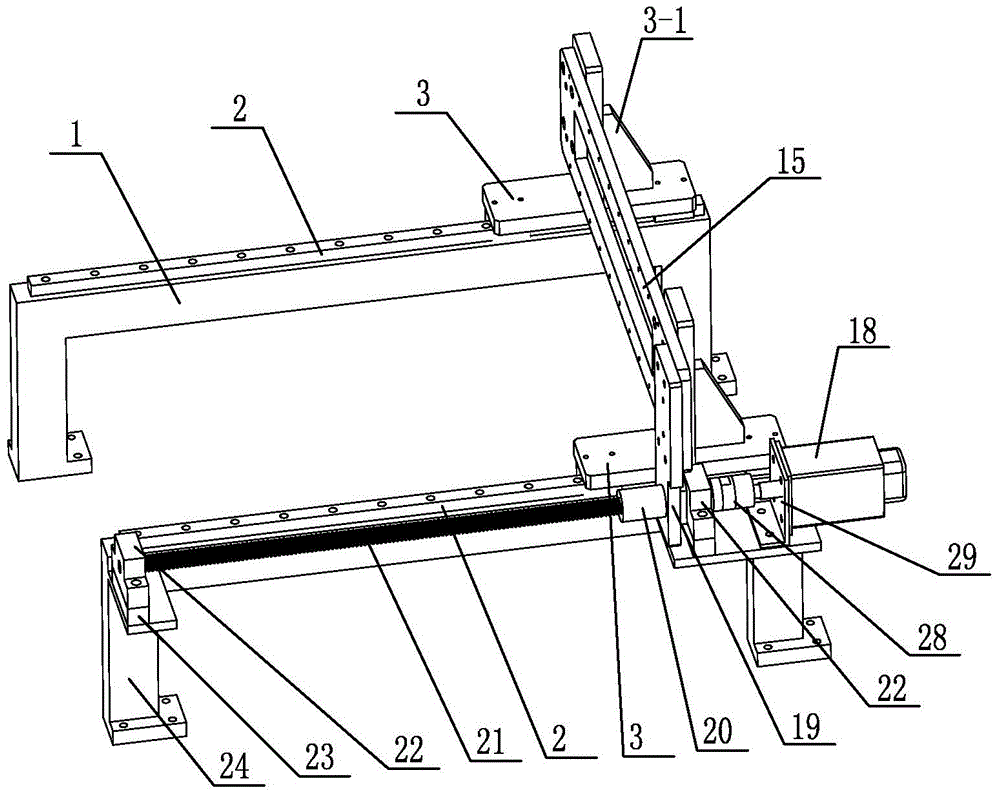

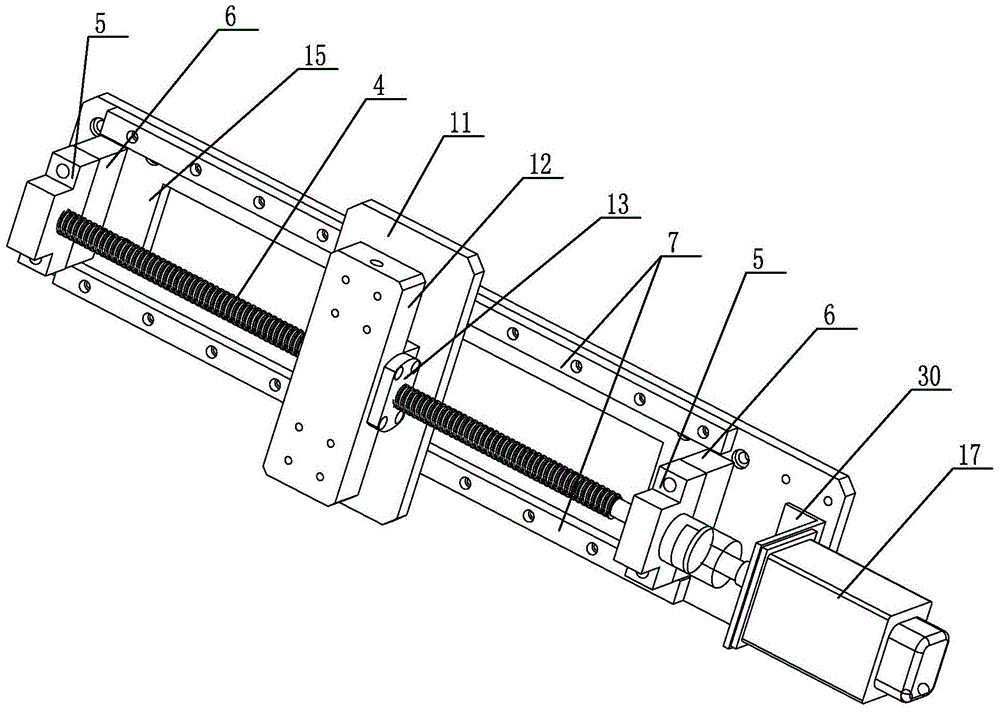

[0020] See Figure 1~4 As shown, the three-axis mechanical arm automatic grasping device of the present invention includes an x-axis direction movement mechanism, a y-axis direction movement mechanism and a z-axis direction movement mechanism.

[0021] See figure 1 , 2 As shown, the X-axis direction movement mechanism of the present invention includes a driven seat 1, a driving seat 24, a first servo motor 18 and a first lead screw 21, and first straight lines parallel to each other are installed on the driven seat 1 and the driving seat 24. The guide rail 2 and the two T-shaped slide blocks 3 are matched with the respective first linear guide rails 2 and can move. The T-shaped slider 3 of the present invention consists of a slide seat and a riser 3-1, and the slide seat is provided with a chute matched with the first linear guide rail 2, so that the T-shaped slide block 3 moves along the first linear guide rail 2, And vertical board 3-1 is then connected with transverse co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com