Jet-flow vacuum machine

A vacuum machine and jet technology, which is applied in the field of vacuuming devices for vacuuming sealed bags, can solve the problems of long-term vacuuming, high power, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

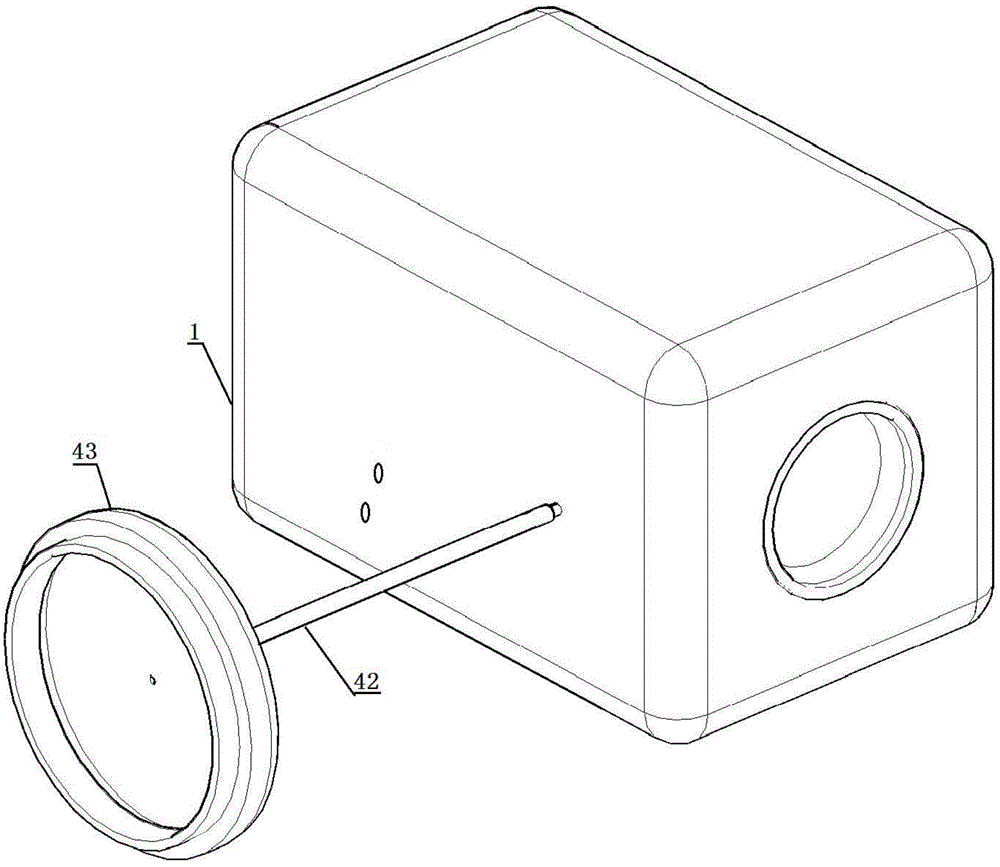

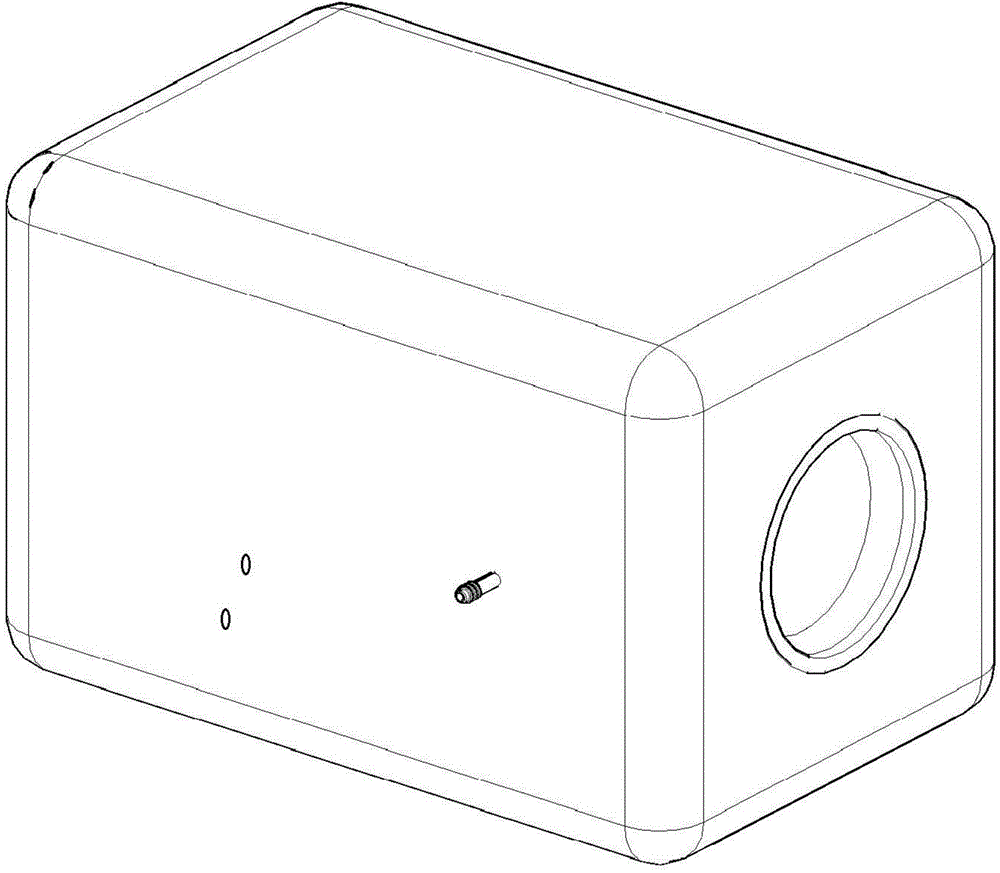

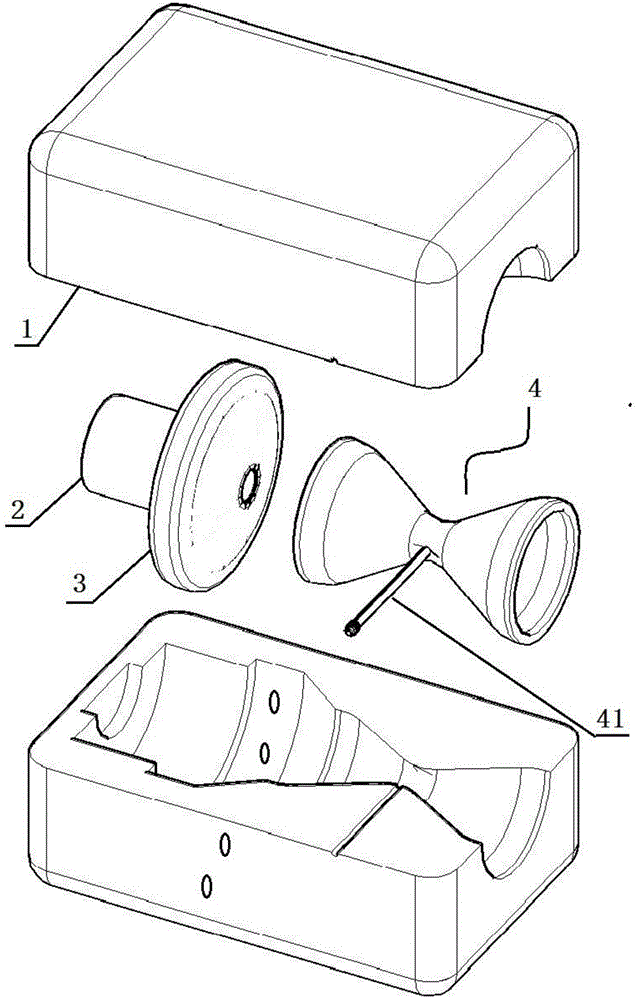

[0015] Such as Figure 1 to Figure 3 As shown, the jet vacuum machine is mainly composed of a casing 1 and a fluidic device placed in the casing. A switch and a power supply / power input interface are provided on the casing. The switch is used to control whether the jetting device is working. The jetting device mainly includes A motor 2, a booster fan 3 and an ejector 4 connected in sequence.

[0016] Such as Figure 4 As shown, the ejector is a Venturi tube structure with two ends large and the middle narrowed, the inlet end of the ejector is sealed and connected with the outlet end of the booster fan 3, and a fixing hole matching the ejector device is provided in the housing. The jet 4 of the jet device is arranged in the fixing hole; the narrow part between the inlet end and the outlet of the jet is provided with a hollow nozzle 41 protruding outwards, and correspondingly, in the fixing hole, there is a Outer nozzle hole matched with the nozzle, the nozzle is placed in the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap