Cement for lap joint of bentonite waterproof blanket and preparation method thereof

A bentonite waterproof blanket and bentonite technology, applied in the direction of adhesive, adhesive type, asphalt material binder, etc., can solve the problems affecting the waterproof and anti-seepage effect of bentonite waterproof blanket, easy to lose water, fall off, etc., to achieve good waterproof and anti- Penetration effect, durable waterproof performance, strong lap joint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the bentonite waterproof blanket lap joint uses the following steps to take the raw materials of the above ratio: use 20% to 40% emulsifier to emulsify 40% to 60% of petroleum asphalt, add 15% to 18 % of sodium bentonite and 2% to 5% of plasticizer, in a reaction vessel at a high temperature of 180°C, use a high-speed shearing machine to mix at a rate of 280 rpm for 30 minutes, and after the raw materials are reacted and fused, form The semi-solid black cement is cooled and packed into a rubber bucket to seal, so that the bentonite cement of the present invention is made. When the bentonite cement of the present invention is used, it can be used just by opening the glue barrel. After the above process is adopted in the present invention, the bentonite clay has strong viscosity, which can make the overlapping of the waterproof blanket more firm. At the same time, it is also flexible and can be well combined with waterproof blankets to adapt to ...

Embodiment approach 1

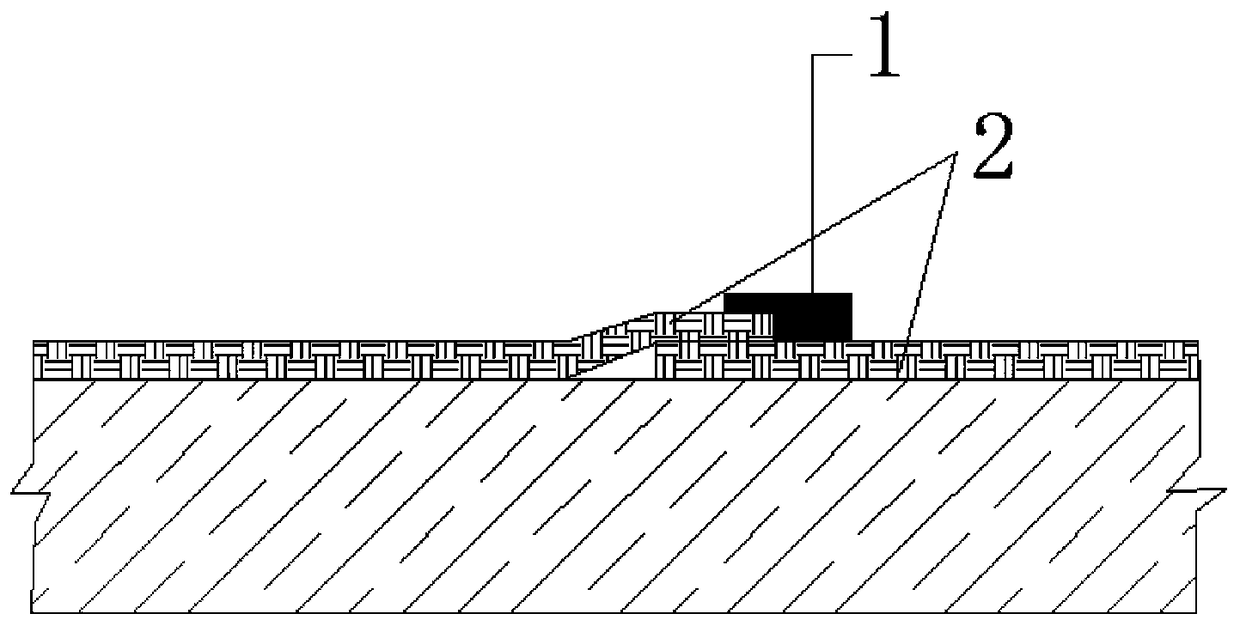

[0025] refer to figure 1 , when the present invention is in use, open the seal cover of the rubber bucket, and directly apply the bentonite clay 1 to the lap joint of the waterproof blanket 2 with a scraper with a length of 20 cm and a width of 4 cm. The width of the smear is 2.5 cm on each side, and the thickness is 0.5 cm. cm, spread evenly along the joint to the end.

Embodiment approach 2

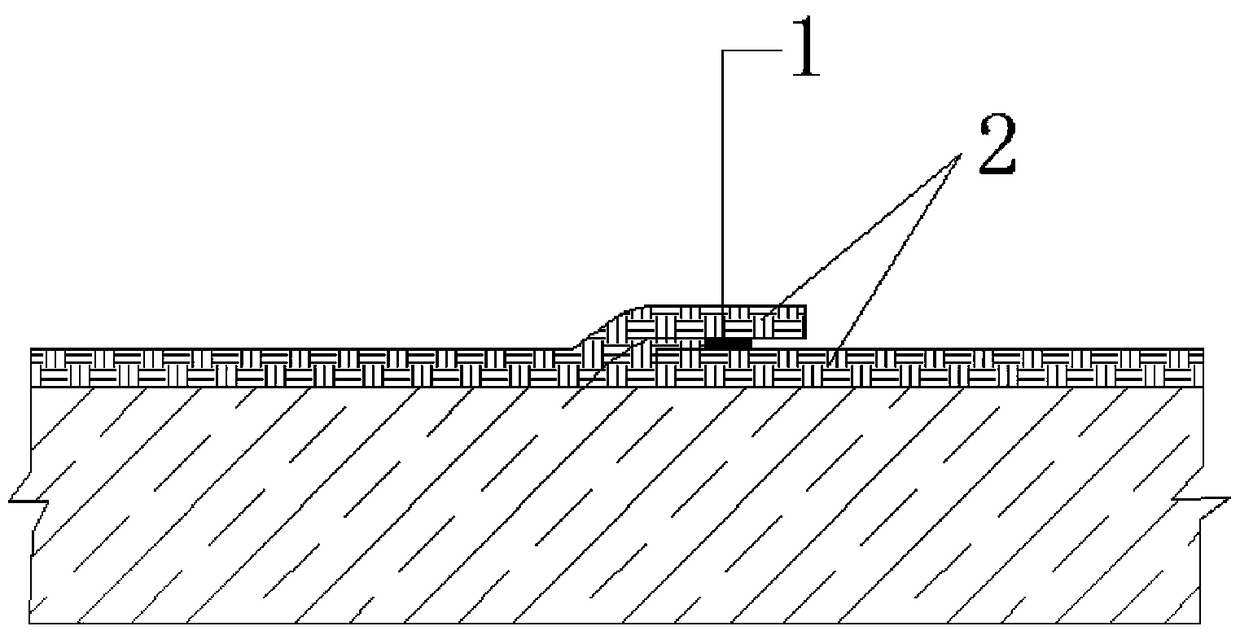

[0027] refer to figure 2 After laying the waterproof blanket, fold back the waterproof blanket 2 lapped on it by 10 cm, and at 2 cm from the edge of the waterproof blanket 2 below the overlap, use a scraper 20 cm long and 4 cm wide to directly apply the bentonite clay 1 on the edge , the width of the smear is 5 cm, the thickness is 0.5 cm, and then spread evenly along the 2 cm edge of the waterproof blanket 2 to the end, and then turn the folded waterproof blanket 2 back and directly compact and overlap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com