Clutch device of decelerating clutch and decelerating clutch

A deceleration clutch and clutch device technology, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve problems such as failure of the deceleration clutch clutch device, and achieve the effects of improving reliability, avoiding meshing tooth wear, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

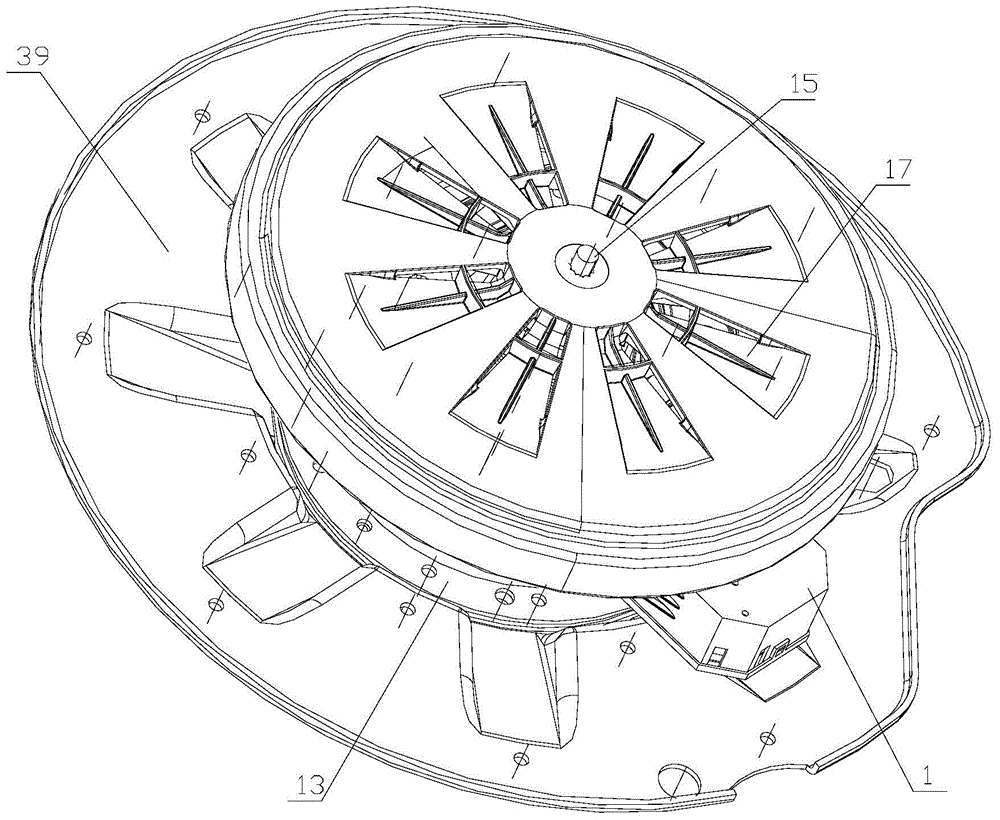

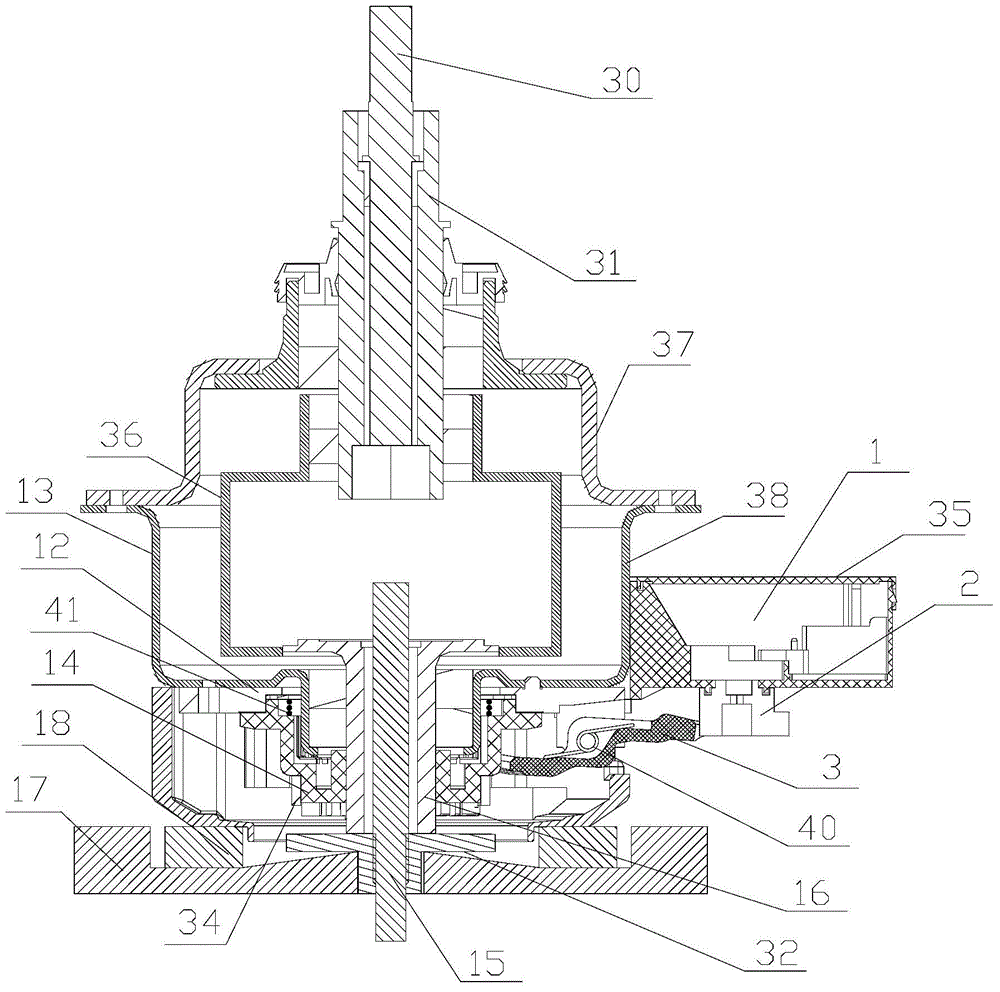

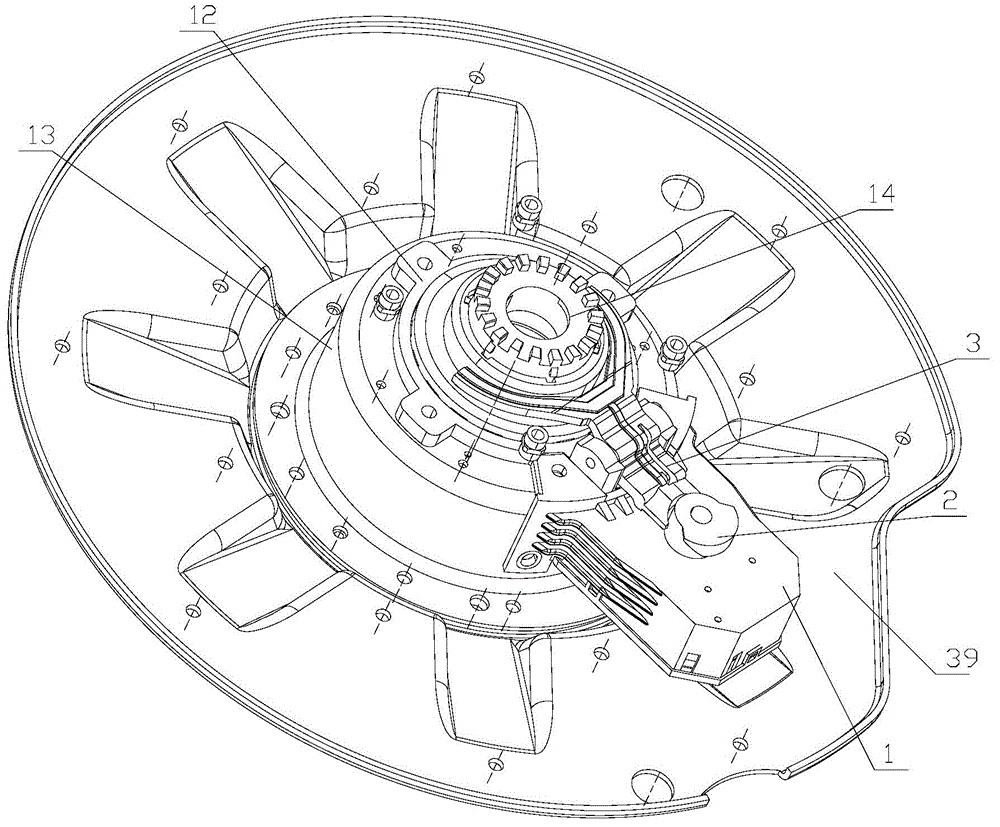

[0039] Such as Figure 3 to Figure 7 as shown in Figure 2-5 As shown, a deceleration clutch clutch driving device described in this embodiment includes a driving motor 1, a driving wheel 2 and a shift fork lever 3, the driving wheel 1 is installed on the output shaft of the driving motor 1, and the circumference of the driving wheel 2 is provided with supports The supporting surface has a height difference in the axial direction. The fork lever 3 is a lever structure with a fixed fulcrum in the middle. The head of the fork lever 3 is a shift fork 6. The shift fork 6 is located below the clutch bushing 14, and the The spring controls the up and down movement of the clutch sleeve 14 together. The tail of the shift fork lever 3 is the driving end 7, and the driving end 7 is provided with a sliding contact surface, which is slidingly matched with the supporting surface; the driving motor 1 drives the driving wheel 2 to rotate, and the tail of the shift fork lever The driving end...

Embodiment 2

[0055] Such as Figure 6 , Figure 8 and Figure 9 As shown, in this embodiment, the upper and lower ends of the clutch sleeve 14 are respectively provided with upper spline teeth 48 meshing with the upper fixed disk and lower spline teeth 49 meshing with the lower dehydration disk. For ease of description, the direction in which the clutch sleeve rotates with the motor rotor 17 is defined as clockwise. The tooth top profile of the upper spline tooth 48 is a slope rising in the clockwise direction; the tooth top profile of the lower spline tooth 49 is a slope descending clockwise. So that. Make the clutch sleeve 14 more smoothly and smoothly mesh when the upper spline teeth 48 and the upper matching spline teeth 50 and the lower spline teeth 49 and the lower matching spline teeth 51 mesh.

[0056] In this embodiment, the lower dehydration tray is composed of a part that is separately set on the top surface of the rotor 17 of the motor or is integrally set with the rotor 17, ...

Embodiment 3

[0064] Such as Figure 8 and Figure 9 As shown, in this embodiment, a clutch bushing, the upper and lower ends of the clutch bushing 14 are respectively provided with upper spline teeth 48 meshing with the upper fixed disk and lower spline teeth 49 meshing with the lower dehydration disk. , At least one of the meshing parts of the upper and lower teeth is provided with a shock-absorbing layer.

[0065] In this embodiment, the shock-absorbing layer is composed of a shock-absorbing sleeve 34 sleeved on the outer wall of the clutch shaft sleeve 14 . The shock absorbing sleeve 34 protrudes from the tooth groove bottom of the lower spline teeth and / or the upper spline teeth, and the shock absorbing sleeve 34 is made of elastic material; preferably, the shock absorbing sleeve 34 is made of It is composed of rubber sleeves that are elastically stretchable and deformable.

[0066] In this embodiment, due to the process of tooth engagement between the clutch sleeve 14 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com