A variable flow drilling and punching integrated nozzle

A technology of variable flow rate and nozzle, which is applied in the direction of drilling and construction with liquid/gas jet, which can solve the problems of low construction efficiency, cumbersome process, and incomplete coverage of water jet, so as to improve construction efficiency, good water jet forming, and replacement convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

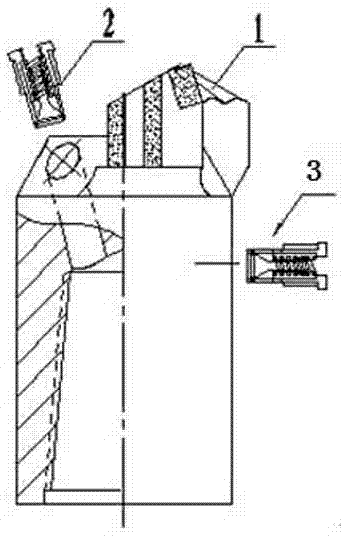

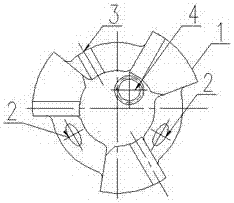

[0017] Nozzle of the present invention is installed on the drill bit, as figure 1 , 2 As shown, the drill bit is composed of a reinforced alloy broken drill bit body 1, two oblique front nozzles 2, radial nozzles 3, and front nozzles 4. The drill bit has nozzles in different directions, oblique front, radial, and front The external thread is installed in the nozzle mounting hole on the drill bit, and the nozzle is installed using a hexagonal wrench to act on the inner hexagonal water outlet 6 of the nozzle.

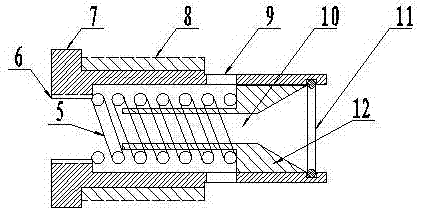

[0018] The concrete structure of described nozzle is: as image 3 As shown, the nozzle includes a nozzle body 7, a coil spring 5, a water jet piston 12 and a cylindrical inner circlip 11,

[0019] The front of the nozzle body has an inner hexagonal nozzle water outlet 6, the outside of the nozzle body has an external thread 8, the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com