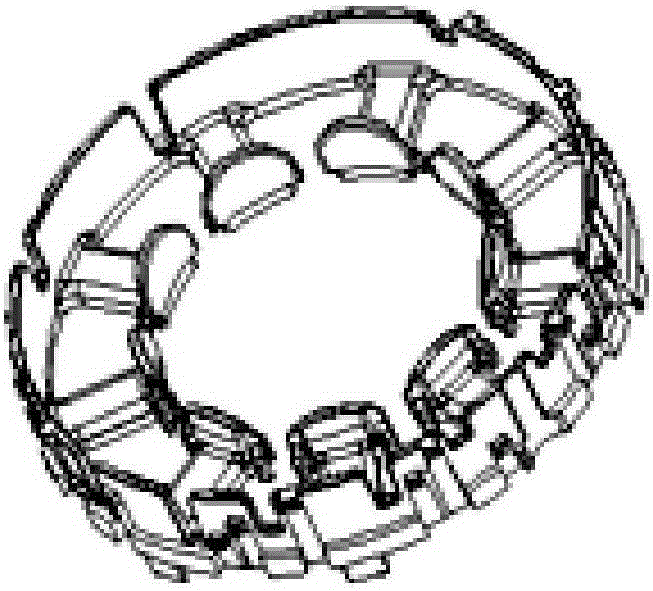

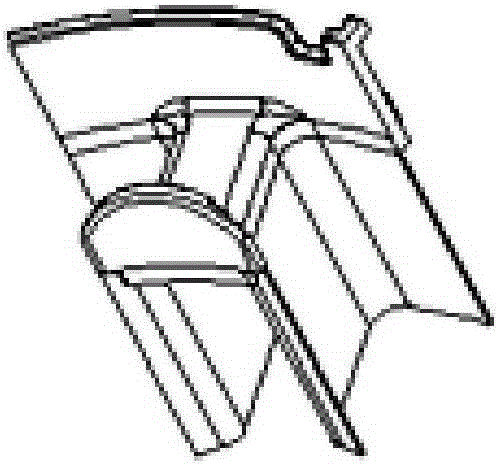

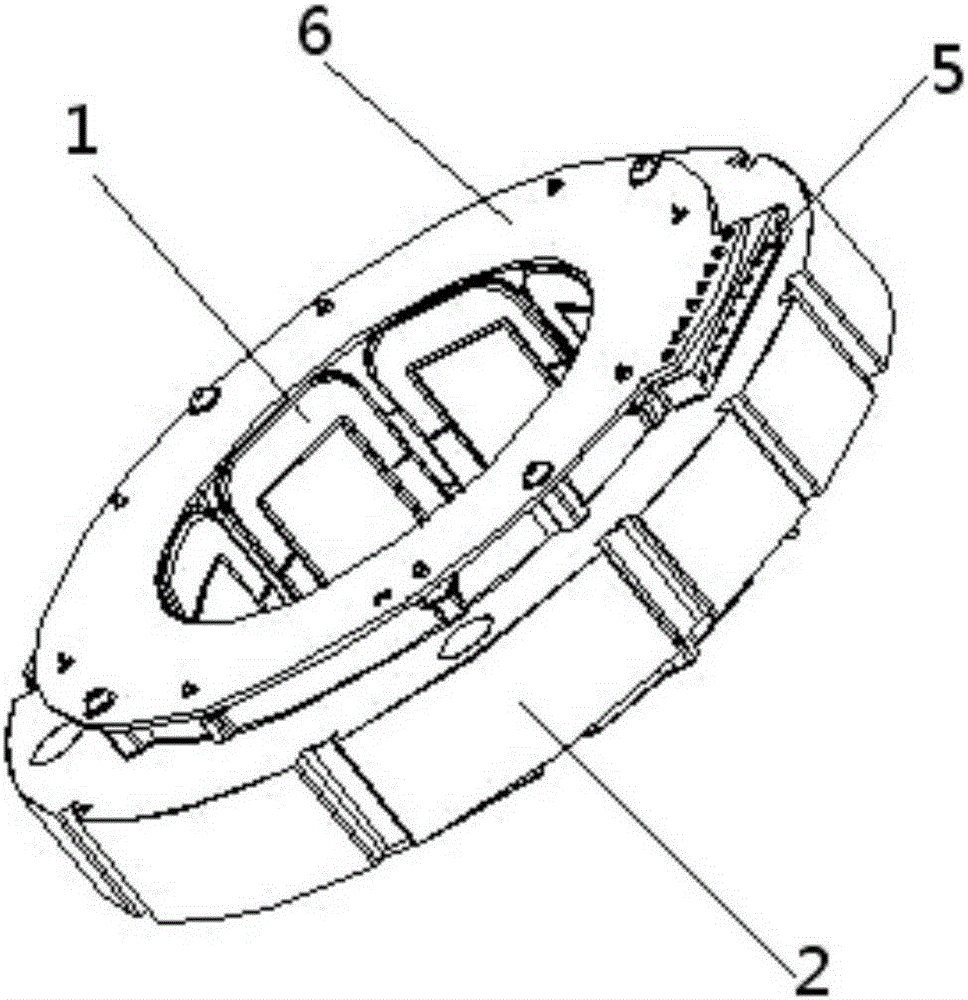

Magnetic bearing stator component and preparation method thereof

A bearing stator, magnetic suspension technology, applied in magnetic bearings, bearing components, bearings, etc., can solve problems such as major safety hazards, wiring confusion, slot paper movement, etc., to achieve strong parts versatility, reduce mold opening costs, and ensure reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below. In the following paragraphs, different aspects of the embodiments are defined in more detail. Aspects so defined may be combined with any other aspect or aspects unless specifically stated otherwise. In particular, any feature which is considered to be preferred or advantageous may be combined with one or more other features which are considered to be preferred or advantageous.

[0042] Terms such as "first" and "second" appearing in the present invention are only for convenience of description, to distinguish different components with the same name, and do not indicate a sequence or a primary and secondary relationship.

[0043] In describing the present invention, it is to be understood that the terms "upper", "lower", "front", "rear", "outer", "inner", "vertical" and "horizontal" indicate an orientation or The positional relationship is based on the orientation or positional relationship shown in the drawings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com