1200L blender

A mixer and sealing mechanism technology, which is applied to mixer accessories, mechanical equipment, mixers with rotating mixing devices, etc., can solve the problems of easy entry of powder into the bearing sealing seat and limited sealing device, and achieve good locking and fixing effect. , convenient and accurate installation, the effect of eliminating hidden dangers of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

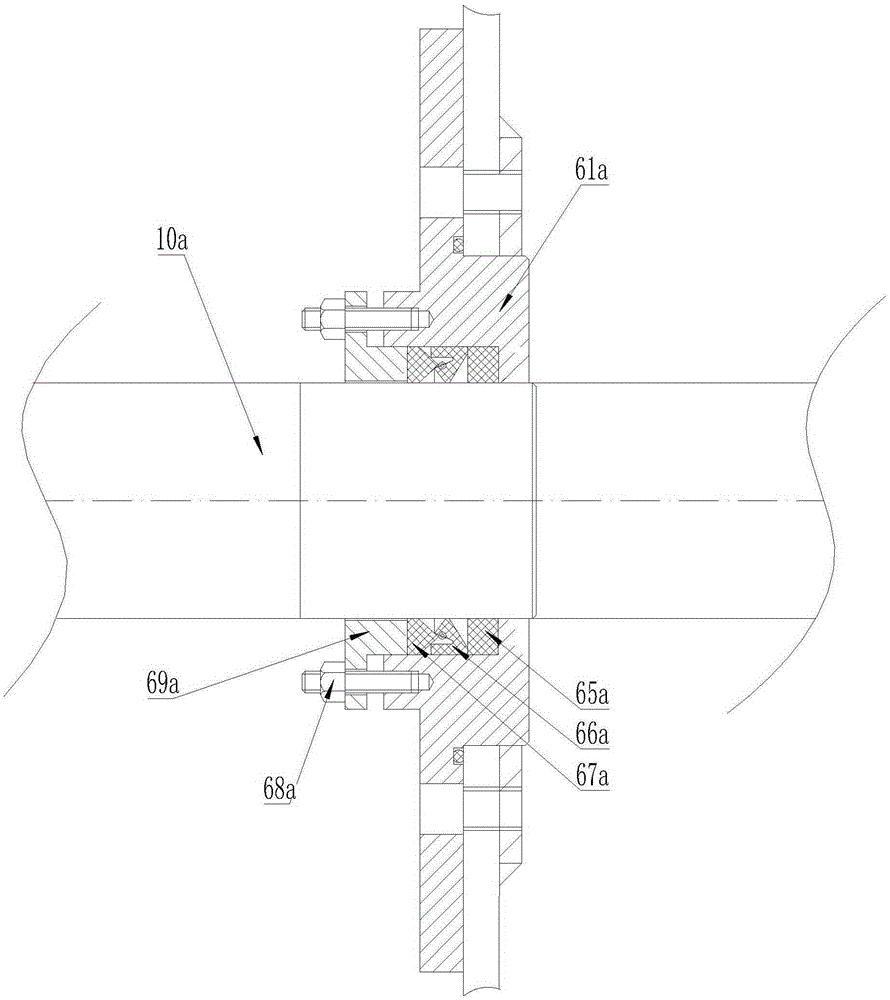

[0037] Embodiment 1: Shaft sealing mechanism

[0038] Such as figure 1 As shown, the rotating shaft sealing mechanism of this embodiment includes a fixed seat I61a with a through hole in the middle part for the rotating shaft to pass through, and a V-shaped sealing gasket I67a is arranged in close contact between the fixed seat I61a and the rotating shaft from left to right in sequence. , Lip gasket I66a and packing gasket I65a.

[0039]In another preferred preferred embodiment of the rotating shaft sealing mechanism, the fixed seat I61a extends toward the direction of the rotating shaft to form a protruding step, and the packing gasket I65a is closely arranged on the left side of the protruding step; the V The left side of the V-shaped gasket I67a is provided with a cover plate I69a that is tight against the V-shaped gasket I67a; the outer peripheral side of the cover plate I69a away from the rotating shaft is located on the left side of the fixed seat I61a, and is connected...

Embodiment 2

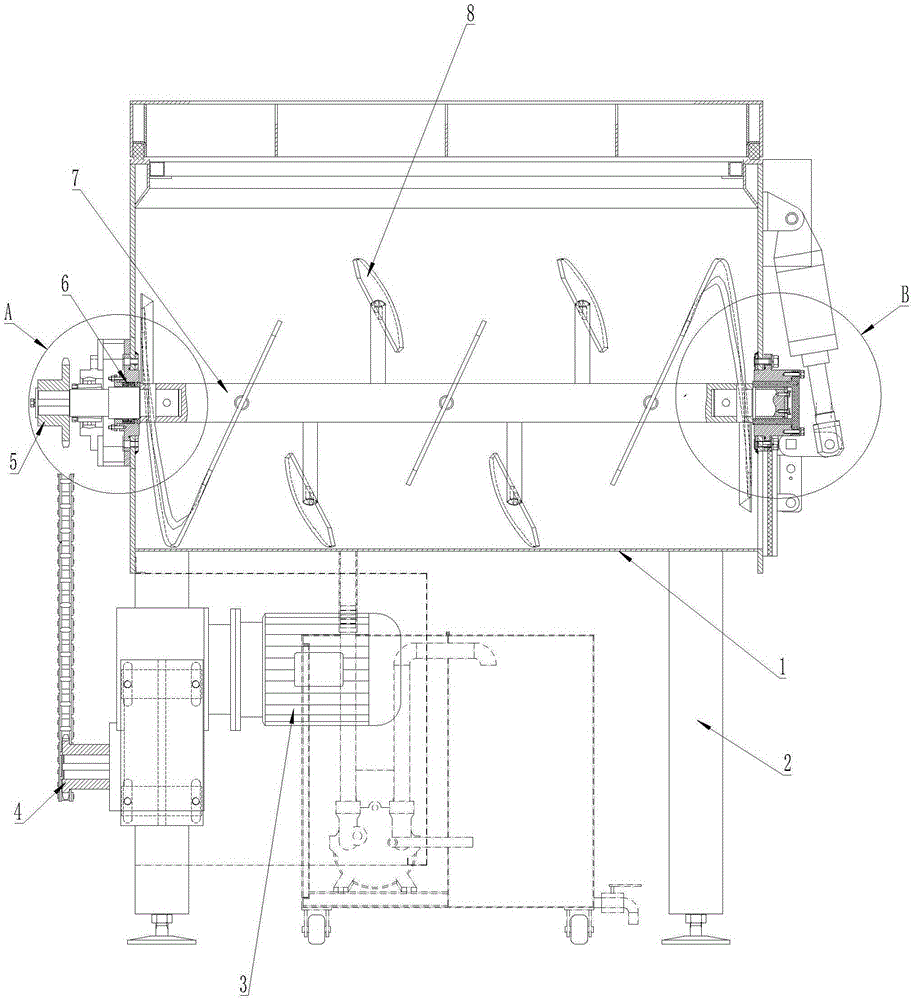

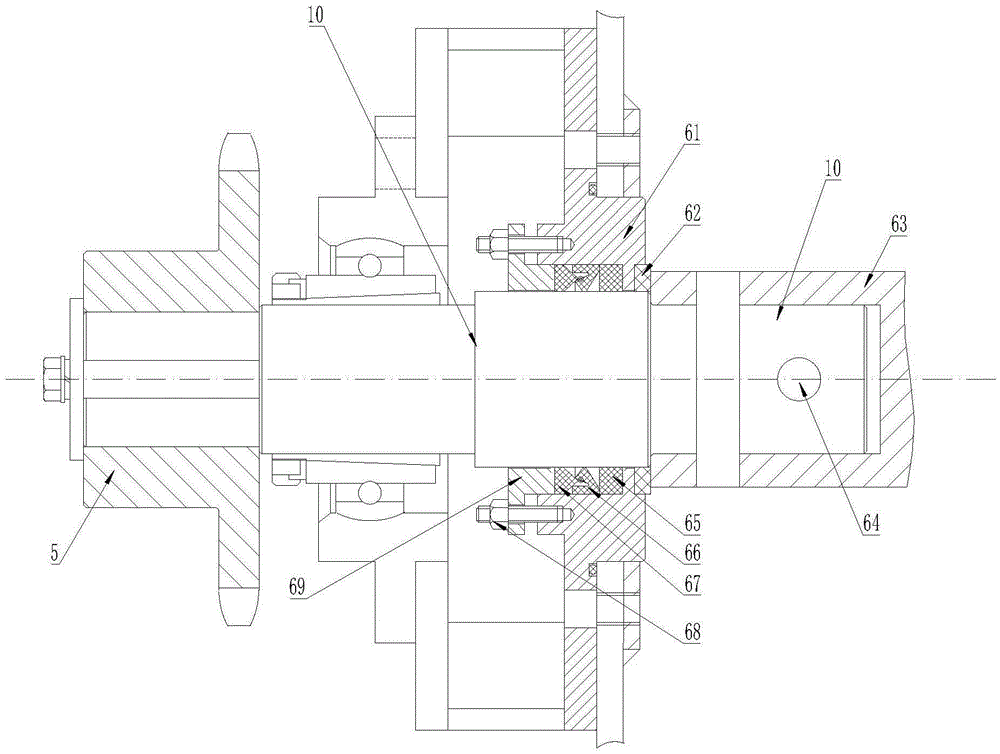

[0040] Example 2: Blender

[0041] Such as Figure 2-4 As shown, the mixer in this embodiment includes a pot body 1, a support frame 2 for supporting and fixing the pot body 1, an auger shaft located inside the pot body 1, and a blade 8 fixed on the auger shaft, The left and right side walls of the pot body 1 are respectively provided with a left through hole and a right through hole corresponding to each other, and the left through hole and the right through hole are respectively provided with an outer spherical bearing with a seat and a self-lubricating bearing. The two ends of the auger shaft and the pot body 1 are rotationally connected through the outer spherical bearing with seat and the self-lubricating bearing respectively; a left sealing mechanism 6 is arranged between the outer spherical bearing with seat and the auger shaft , the left sealing mechanism 6 is composed of a V-shaped sealing gasket 67, a lip sealing gasket 66 and a packing sealing gasket 65 in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com