Process and equipment for regulating and controlling crystal forms of glass sand raw materials

A high-purity quartz sand and raw material technology, applied in lighting and heating equipment, furnace control devices, furnaces, etc., can solve the problem that impurities and gas-liquid inclusions cannot be completely exposed, the transformation of quartz crystal form is not considered, and the difficulty of impurity removal process is increased, etc. problems, achieve the effect of reducing re-pollution, reducing calcination time, and reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

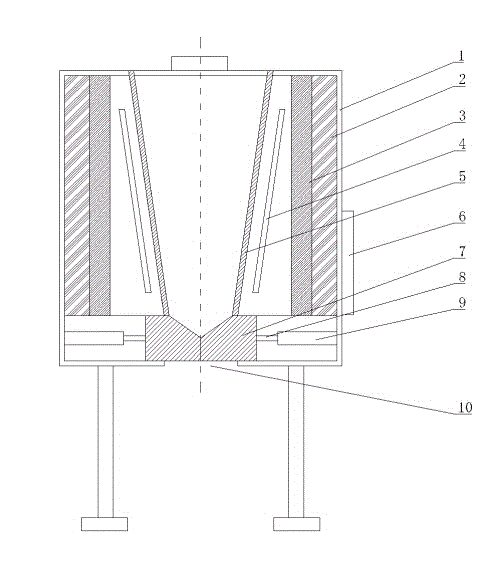

[0019] now attached figure 1 , the present invention will be further described in detail. A process for regulating the crystal form of high-purity quartz sand raw materials. The high-purity quartz sand raw materials are added from the top of the calciner along the slope of the furnace lining. When adding, the temperature in the furnace is controlled at 600°C-800°C and heated to 900°C. The heating rate is 4-6°C / min, keep warm for 1-2 hours, continue to heat up to 1200°C-1300°C after the end of the heat preservation, the heating rate is 8-10°C / min, keep warm for 2-4 hours, after the end of the heat preservation, the cylinder control unit will automatically discharge the material The furnace door is opened, and the calcined high-purity quartz sand raw material quickly falls from the discharge port and enters the next process. It saves heating time, reduces heat loss, reduces energy consumption, truly realizes automation, reduces manual operations, and saves production costs.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com